-

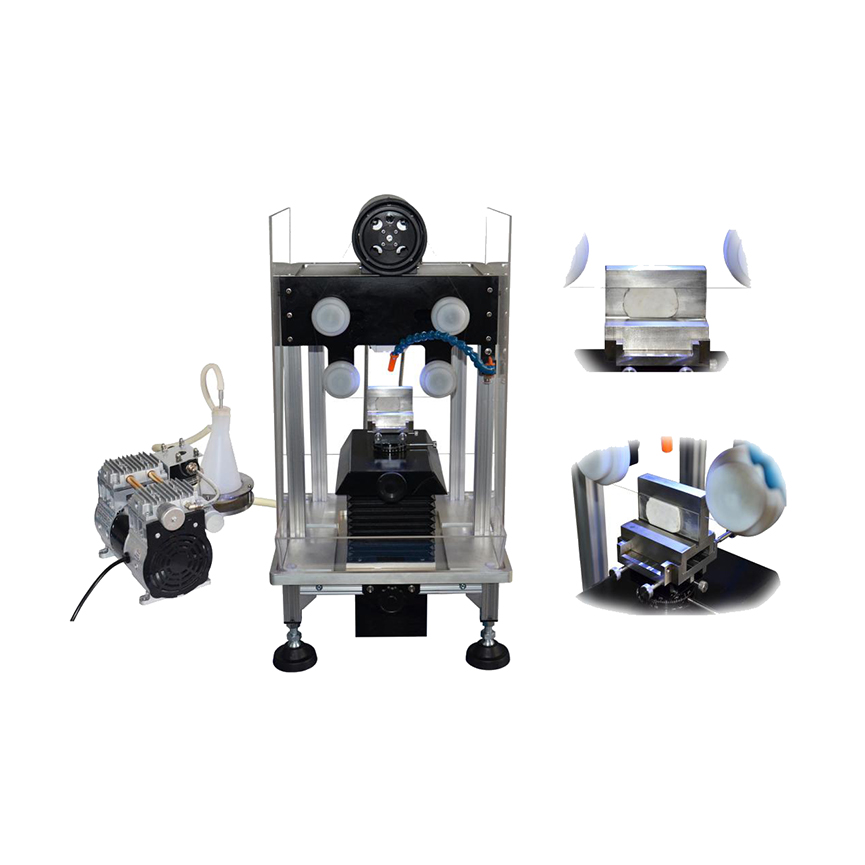

Diamond Wire Saw For Cutting Max. 50mm

STX-202A Compact Diamond Wire Saw is specially designed for material researchers. It is used for precision cutting of fragile material samples. It can slice, cut, and square materials. The rotary workbench can also cut the sample at a certain angle. The materials include ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials. When using it for ultra-thin precision cutting, the thickness of samples (within the range of about 1 inch) can reach 0.08mm.

Send Email Details -

Swing Rotary Sample Fixture and Rotation Control System

STX-202A-A swing/rotary sample fixture is mainly used for samples with extremely high requirements for roughness and flatness of sample surface when cutting with a diamond wire saw.

Send Email Details -

Diamond Wire Saw With Pneumatic Tension System

STX-202AQ Compact Diamond Wire Saw is specially designed for material researchers. It is used for precision cutting of fragile material samples. It can slice, cut, and square materials. The materials include ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials.The tension wheel adopts pneumatic tensioning mode, and the air pressure can be adjusted according to the thickness of the wire diameter. When the wire diameter is too thin, it can effectively protect the cutting wire from breaking due to excessive tension.

Send Email Details -

Geological Thin Slice Cutting System

STX-202A geological thin slice cutting system is aimed at processing rock samples in geological industry.

Send Email Details

It can adsorb geological thin slice by connecting an oilless vacuum pump to a suction filter tank and a vacuum chuck.

The required thickness is much easier to achieve by suing thinner diamond wire when cutting the slice. -

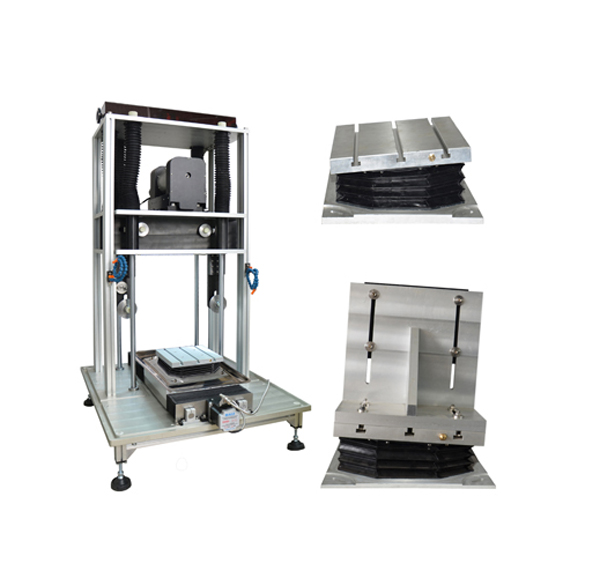

Swing Sample Fixture for Diamond Wire Saw

STX-1200-YB swing sample fixture is specially developed and designed for STX-1203 automatic diamond wire saw. It is mainly used for cutting high hardness materials (such as silicon carbide, silicon nitride, alumina ceramics, zirconia, sapphire, Jade, etc.) and low hardness materials (such as barium fluoride, graphite, KDP, etc.). It can also be used for precision cutting of brittle materials such as crystals, ceramics, glass, thermoelectric materials (such as bismuth telluride, lead telluride, silicon germanium alloys, etc.), rock samples, mineral samples, PCB boards, refractory materials, composite materials, biological and biomimetic composite materials or used for cutting difficult-to-cut materials such as metal materials, rubber and other organic materials. STX-1200-YB swing sample fixture swings left and right during operation. It can reduce the contact area between the cutting wire and the sample, prolong the contact time, improve roughness and flatness of the sample surface, and reduce wire cutting traces on the sample. At the same time, STX-1200-YB swing sample fixture is equipped with an elevated frame, which can increase swinging extent of the sample and increase the wire swing speed, thereby increasing the grinding efficiency per unit time and improving the cutting speed of the sample.

Send Email Details -

Endless Diamond Wire Saw

STX-201 Endless Precision Diamond Wire Saw is an ideal equipment for cutting fragile, brittle, small volume and other materials. Diamond-embedded wire is especially suitable for cutting of various crystals and substrates without damage, such as ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials and biomedical materials. The cutting speed is not only related to the rotation speed of the annular diamond wire, but also related to the weight of the applied force.

Send Email Details -

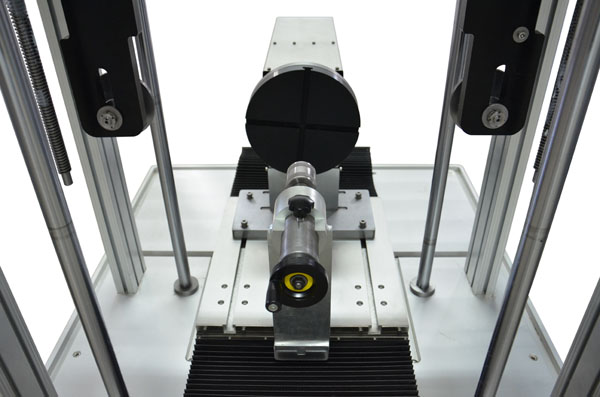

Axis Swing/Rotary Sample Fixture and Rotation Control System

STX-1200-A axis swing/rotary sample fixture is specially developed and designed for STX-1203 automatic diamond wire saw. It is mainly used for cutting high hardness materials (such as silicon carbide, silicon nitride, alumina ceramics, zirconia, sapphire, Jade, etc.) and low hardness materials (such as barium fluoride, graphite, KDP, etc.). The STX-1200-A axis swing/rotary sample fixture can perform both swing cutting and rotary cutting in the opposite direction to that of the working diamond wire. For a larger or heavier sample, the top part of the sample should be fixed with a spindle, so the sample top will rotate simultaneously with the spindle. In this way, the cutting efficiency per unit time is improved, the actual cutting time is shortened, the service life of the diamond wire is prolonged, the roughness and flatness of the cutting surface is significantly improved, and the cutting wire traces on sample surface are reduced, resulting in a high-quality cutting surface.

Send Email Details -

Automatic Diamond Wire Saw With Electric Angle Stage

STX-203 fully automatic diamond wire saw is specially designed for material researchers. It is used for precision cutting of fragile material samples. It can slice and cut materials. The materials include ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials.

Send Email Details -

Electric Wire Installer

STX-2500 (and STX-2500/100QX) electric wire installer is suitable for diamond wire saws. It adopts a low-speed and large-torque motor to drive the spooler, which can rotate CW and CCW. The electric magnetic powder damper controls rotational resistance through current. When in use, install the drive motor together with the fixing plate onto the pulley side of the spooler (remove the original fixing plate), and fix the magnetic powder damper on the side of the device.

Send Email Details