-

Swing Rotary Sample Fixture and Rotation Control System

STX-202A-A swing/rotary sample fixture is mainly used for samples with extremely high requirements for roughness and flatness of sample surface when cutting with a diamond wire saw.

Send Email Details -

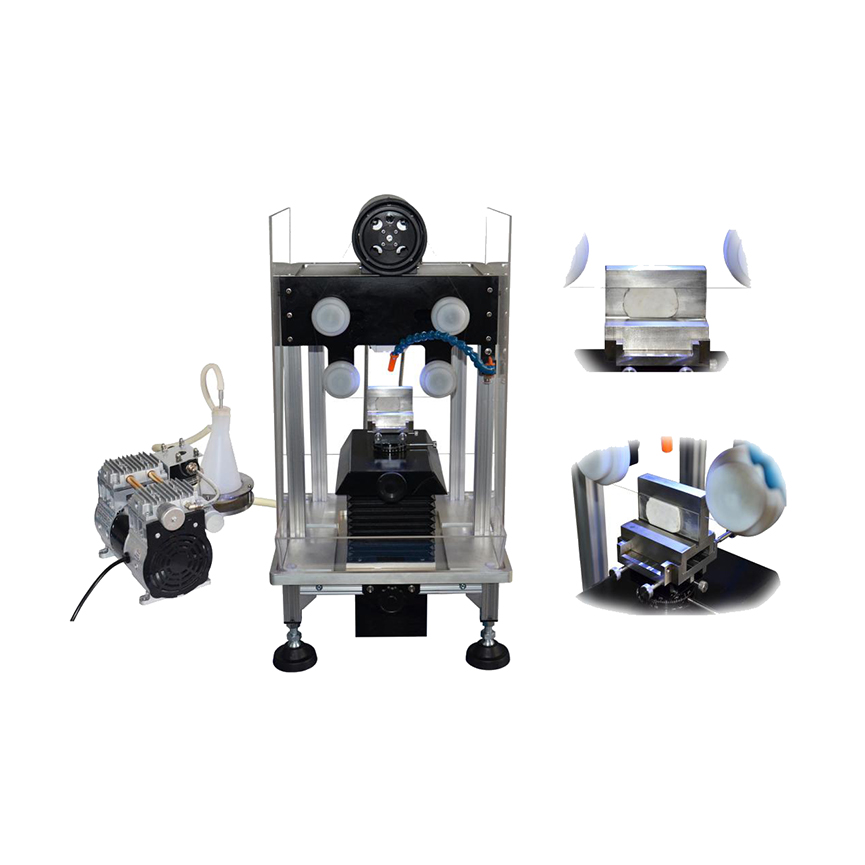

Geological Thin Slice Cutting System

STX-202A geological thin slice cutting system is aimed at processing rock samples in geological industry.

Send Email Details

It can adsorb geological thin slice by connecting an oilless vacuum pump to a suction filter tank and a vacuum chuck.

The required thickness is much easier to achieve by suing thinner diamond wire when cutting the slice. -

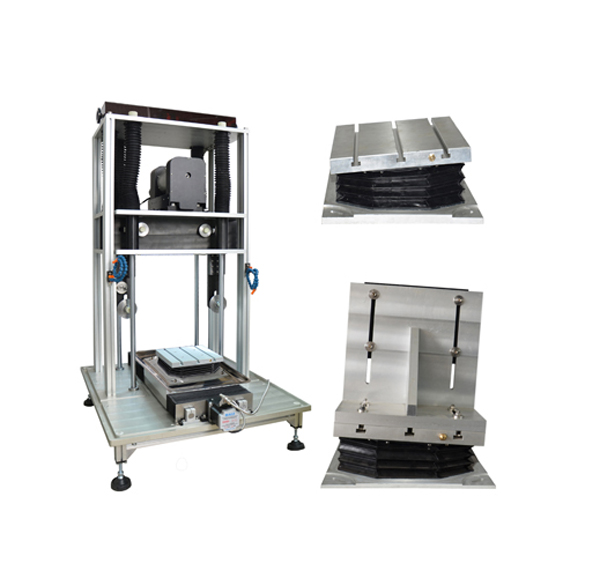

Swing Sample Fixture for Diamond Wire Saw

STX-1200-YB swing sample fixture is specially developed and designed for STX-1203 automatic diamond wire saw. It is mainly used for cutting high hardness materials (such as silicon carbide, silicon nitride, alumina ceramics, zirconia, sapphire, Jade, etc.) and low hardness materials (such as barium fluoride, graphite, KDP, etc.). It can also be used for precision cutting of brittle materials such as crystals, ceramics, glass, thermoelectric materials (such as bismuth telluride, lead telluride, silicon germanium alloys, etc.), rock samples, mineral samples, PCB boards, refractory materials, composite materials, biological and biomimetic composite materials or used for cutting difficult-to-cut materials such as metal materials, rubber and other organic materials. STX-1200-YB swing sample fixture swings left and right during operation. It can reduce the contact area between the cutting wire and the sample, prolong the contact time, improve roughness and flatness of the sample surface, and reduce wire cutting traces on the sample. At the same time, STX-1200-YB swing sample fixture is equipped with an elevated frame, which can increase swinging extent of the sample and increase the wire swing speed, thereby increasing the grinding efficiency per unit time and improving the cutting speed of the sample.

Send Email Details -

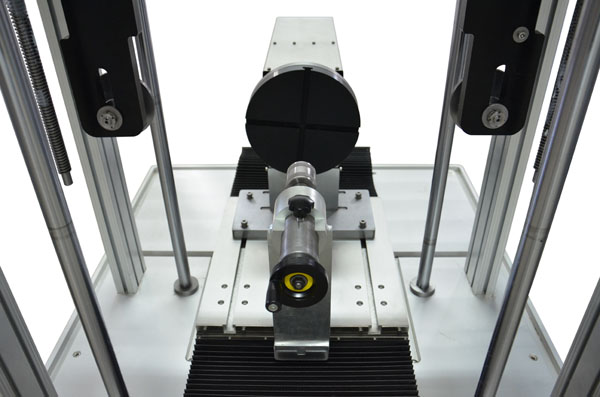

Axis Swing/Rotary Sample Fixture and Rotation Control System

STX-1200-A axis swing/rotary sample fixture is specially developed and designed for STX-1203 automatic diamond wire saw. It is mainly used for cutting high hardness materials (such as silicon carbide, silicon nitride, alumina ceramics, zirconia, sapphire, Jade, etc.) and low hardness materials (such as barium fluoride, graphite, KDP, etc.). The STX-1200-A axis swing/rotary sample fixture can perform both swing cutting and rotary cutting in the opposite direction to that of the working diamond wire. For a larger or heavier sample, the top part of the sample should be fixed with a spindle, so the sample top will rotate simultaneously with the spindle. In this way, the cutting efficiency per unit time is improved, the actual cutting time is shortened, the service life of the diamond wire is prolonged, the roughness and flatness of the cutting surface is significantly improved, and the cutting wire traces on sample surface are reduced, resulting in a high-quality cutting surface.

Send Email Details -

Electric Wire Installer

STX-2500 (and STX-2500/100QX) electric wire installer is suitable for diamond wire saws. It adopts a low-speed and large-torque motor to drive the spooler, which can rotate CW and CCW. The electric magnetic powder damper controls rotational resistance through current. When in use, install the drive motor together with the fixing plate onto the pulley side of the spooler (remove the original fixing plate), and fix the magnetic powder damper on the side of the device.

Send Email Details -

Heating Plate

The heating plate is specially developed for material processing and material research laboratories. It is made of aluminum as a whole, and a single-chip microcomputer is used as the core control component. The temperature is adjustable, and the heat dissipation is fast after use. The heating plate is mainly suitable for materials whose properties will not change during heating, i.e. materials will not be affected by heating. It is especially suitable for heating temperature-sensitive materials (such as crystals, semiconductors, ceramics, metals, etc.).

Send Email Details -

Coolant Circulating Tank With Pump

It is suitable for small scale production and cooling water transportation. It is mainly used for the UNIPOL series grinding and polishing machines manufactured by our company. YJXZ-12 liquid stirring circulating pump not only has the function of conventional circulating pumps, but also adds stirring function. YJXZ-12 liquid stirring circulating pump can also be used to transport cooling circulating water when the cutting machine is working.

Send Email Details -

Through-Microscope

3R Wireless WIFI Digital Microscope allows you to study tiny objects. WiFi wireless connection not only frees yourself from wired connection, but also allows others to share wireless connection to watch the tiny world under the microscope together. 3R wireless WIFI digital microscope can be used together with STX series diamond wire saws and SYJ-400CNC dicing saw manufactured by our company.

Send Email Details -

Automatic Recirculating Filter System

The working steps of the automatic filtration circulating water tank: the cooling liquid in the equipment enters the filter cotton in the return water tank through the return port, so that the large particle cuttings in the cooling liquid will stay in the filter cotton. The coolant that has been filtered for the first time flows into the tank for precipitation. After the coolant inside the tank reaches a certain capacity, it flows into the second sedimentation pool through the overflow port, and finally flows to the equipment from the outlet joint of the circulating pump after being filtered by the filter screen..

Send Email Details