Mini Arc Melter

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 10 working days

Supply capacity 50 sets

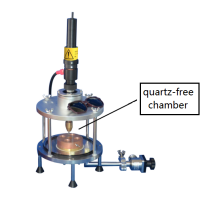

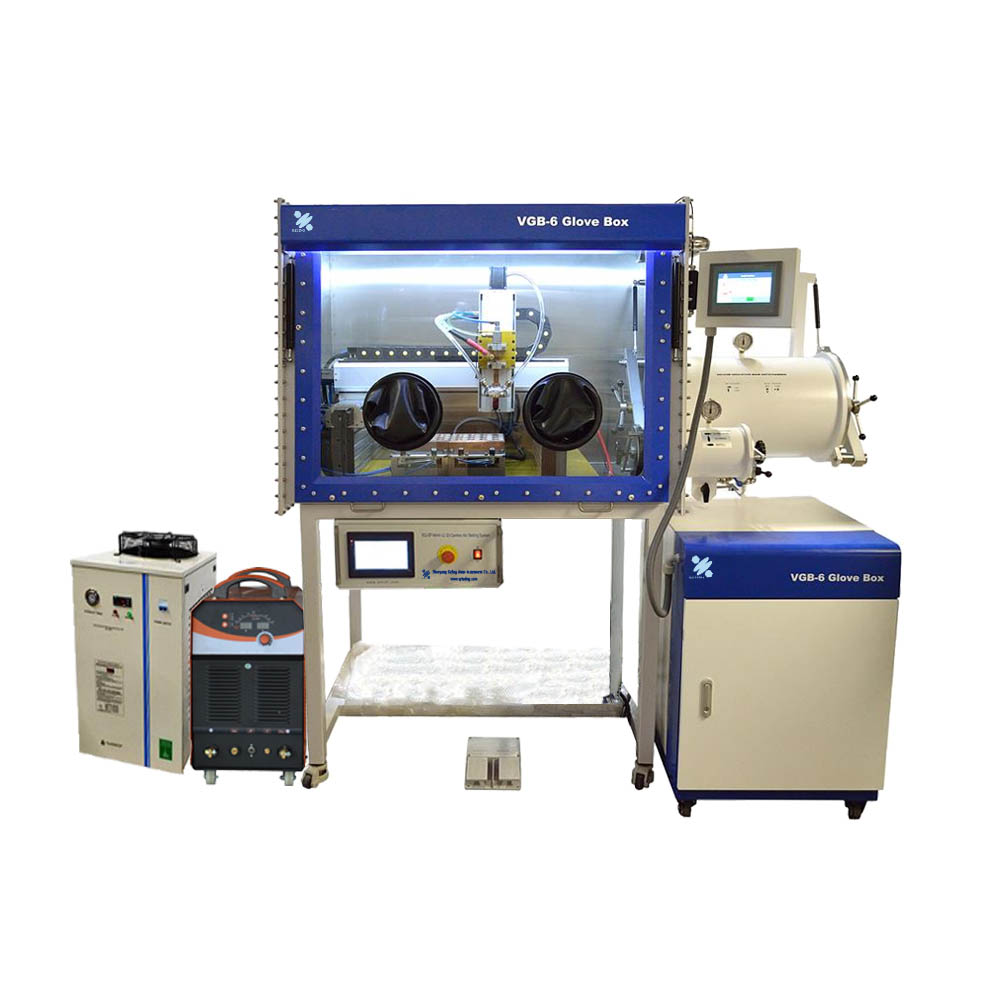

SP-MSM130 Micro Arc Melting Furnace (Quartz Chamber) is an inexpensive small vacuum arc melting furnace that can be used in a glove box. It adopts tungsten electrodes and removable crucibles. The smelting temperature of the equipment can exceed 3500℃, and then is rapidly cooled down. It adopts a clear quartz chamber, the smelting of the sample can be observed 360 degrees. SP-MSM130 is an inexpensive experimental tool for sample smelting and heat treatment and phase diagram study.

Main Features

1. The application environment is diversified, and the equipment can be used in the glove box or in the atmosphere.

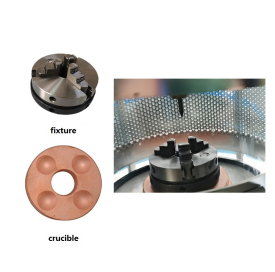

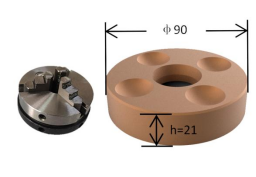

2. Multifunctional detachable crucible (outer diameter 90mm), smelting sample weight ≤8g (4 smelting cas are hemispherical φ23×7mm, the crucible is detachable and customizable.)

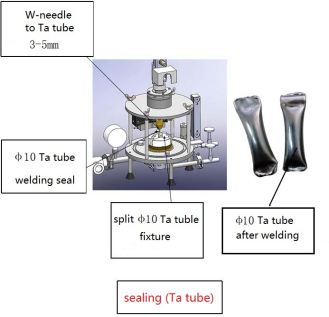

* (Standard) Welding and sealing tantalum (Ta) tube cavity, opening: φ29, including a set of telescopic clamps, clamping range: φ3~φ16mm, length: 30~90mm

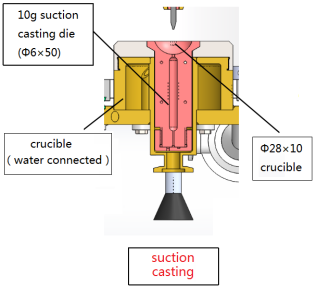

* (Optional) Suction casting crucible, 10g suction casting mold/die (φ6×50), φ28×10

3. Transparent quartz chamber, equipped with protective cover, to observe the smelting of samples.

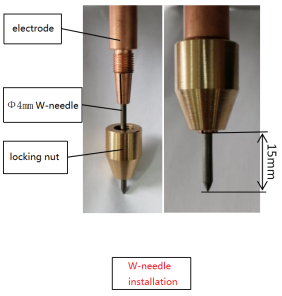

4. Equipped with 4mm diameter tungsten electrode, the electrode rod does not need water cooling (note that the continuous smelting time cannot exceed 30s)

|  |

|  |

Technical Parameters

Product Name | SP-MSM130 Micro Arc Melting Furnace | |

Major Parameters (Specification) | Main machine 1. Equipped with barometer (-0.1 to +0.15MPa) 2. Argon arc power supply, input voltage 220VAC, single-phase, 50Hz. 3. Tungsten electrode: Equipped with a tungsten electrode with a diameter of 4mm. The angle and height of the electrode gun can be adjusted. It is used for melting multiple samples. Smelting sample weight ≤8g (calibrated with iron), temperature up to 3500℃ 4. Current adjustment: an integrated button on the upper part of the control handle controls arc ignition and current adjustment, and the adjustment range is 30~255A. 5. Multifunctional water-cooled crucible: equipped with water cooling, 5 cavities, 4 smelting workstations are hemispherical φ23×7mm One workstation encapsulated Ta tube with a diameter of φ10~φ20mm and a length of 30~90mm. Crucible is removable and customizable. 6. Chamber: Quartz chamber is used, and the inner size of chamber is φ168×142mm. | |

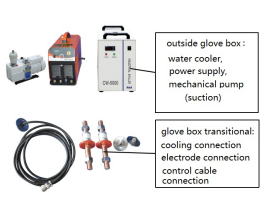

vacuum pump 1. Model: VRD-8 mechanical pump 2. Power supply: single-phase/three-phase 3. Motor power (kW): 0.75/0.55 4. air intake and exhaust DN: KF25 5. Oil consumption (L): 0.9-1.5 6. Motor speed (rpm): 50 Hz/1440, 60 Hz/1720 7. Working ambient temperature (℃): 5-40 8. Noise (dB): ≤58 9. Weight (kg): 30 |

| |

Water-cooling device 1. Model: KJ5000 water-cooling device 2. Working voltage: AC 208V-240V 50Hz/60Hz 3. Working current: 3.5-5.6A 4. Water tank volume: 6L 5. Water flow rate: 16L/min 6. Water inlet and outlet: copper nozzle with outer diameter Ø10mm 7. Cooling capacity: 722Kcal/h (2866Btu/h) |

| |

power supply 1. Model: WS-250 2. Input voltage: AC220V±15%, 50Hz, single item 3. Input current: ≤18.9A ( an air switch of ≥25A is needed) 4. Rated output voltage: 20V 5. Output current regulation: 10-250A (DC) 6. Use current control rotary knob on the power supply to control the power output. 7. Rated input power: 6.3kVA |

| |

Product Dimension and Weight | Dimension: 430×225×550mm Weight: 13.5kg | |

Application Environment | Use in the atmosphere

| |

Use in a glove box

| ||

Optional Accessories

type | name | functional type | picture |

Optional Components | Suction Casting Component | (optional) |

|

Tube-Sealing Component | (optional) | | |

Optional Crucible | Standard Crucible Hemispherical φ23×H7 four-cavity (each station ≤8g 304 calibration), with a sealing cavity in the middle (Opening hole φ29, including a set of telescopic clamps, clamping range φ3~φ16mm, length 30~90mm) | (standard) | |

Optional Large Cavity Crucible φ40×H8 (≤50g 304 calibration) | (optional) |

| |

Customized Irregular Shaped Crucible | (optional) |

| |

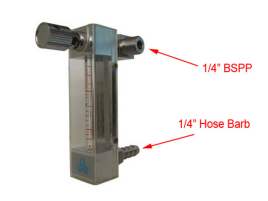

Optional Accessories | Float Gas Flow Meter (used to control the amount of gas intake) | (optional) |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics