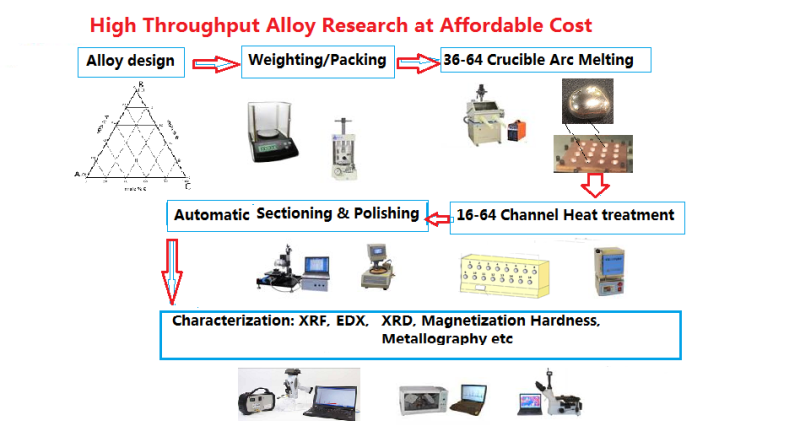

Arc Melting System For High Throughput Alloy Formation

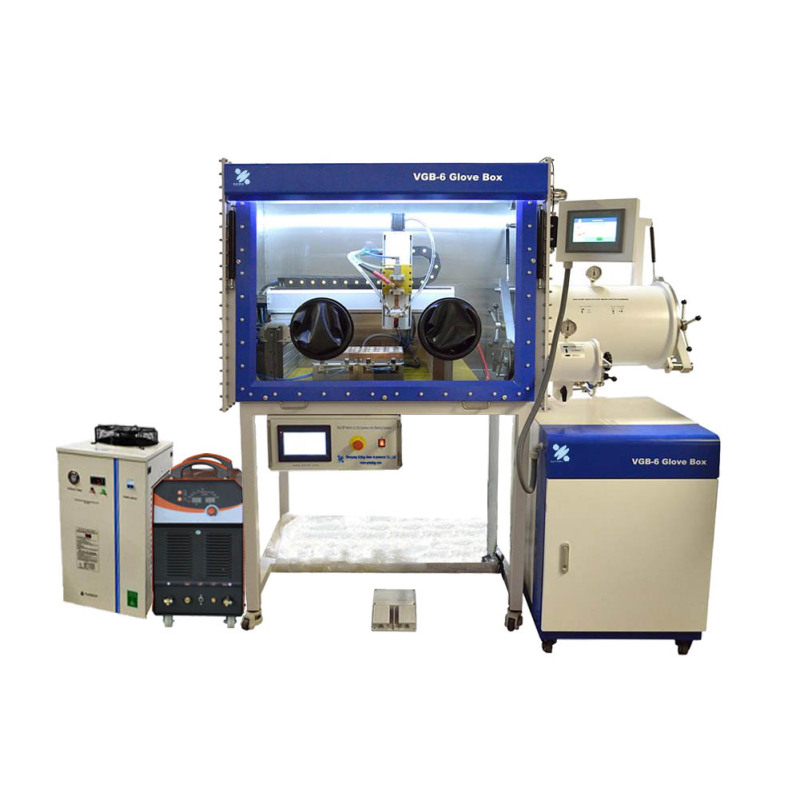

SP-MSM360 32-Cavity High-Throughput Arc Melting System is a multi-station (the number of stations can be customized according to requirements) high-throughput arc melting system, and is specially designed for research experiments on alloy structure and phase diagram. It is composed of a vacuum glove box, a X-Y-Z axis movable machine tool and an arc melting furnace. It can smelt 32 groups of samples at one single time, and its melting temperature can be as high as 3500℃.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Main Features

1. The shell of the vacuum glove box is made of 3mm thick 304 stainless steel, and the observation window is made of high-strength tempered glass.

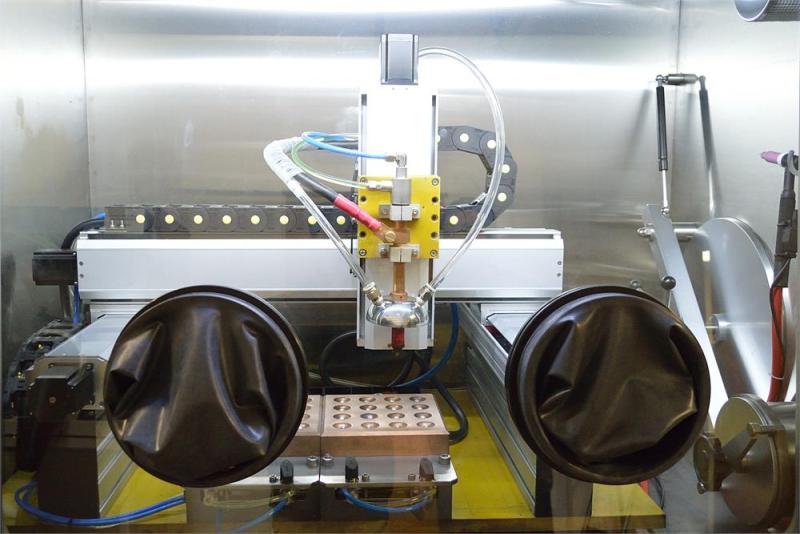

2. The water-cooled crucible group (180mm×180mm)×2 are fixed on the insulating bottom plate. The X-Y-Z axis position controller adopts touch screen control. After the program is set and started, the controller can move the tungsten electrode to each water-cooled crucible for melting according to the program.

3. Equipped with KJ-5000 circulating water cooling machine.

4. The system needs to use high-purity argon with a purity of 99.999%, H20≤5ppm, O2≤5ppm or better.

Technical Parameters

Product Name | SP-MSM360 32-Cavity High-Throughput Arc Melting System |

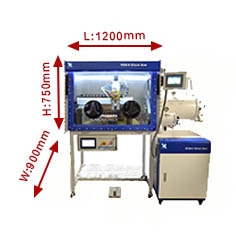

Major Parameters (Specification) | Vacuum glove box 1. The size is 1200mm×900mm×750mm with a single front opening window. Transition bin: 360mm×600mm/150mm×300mm 2. Single-column purification, equipped with a circulating fan, and automatic cleaning function

Gas purification system 1. The automatic water purification system can reduce the moisture and oxygen in the glove box to below 1PPM. 2. The dew point meter and oxygen analyzer (0-999ppm) are installed inside the glove box with an accuracy of ±0.1ppm. 3. A heating module is installed in the circulation system, which can regenerate the dehydrant and deoxidizer. 4. The automatic pressure control system can keep the air pressure constant in the glove box. 5. The operations used by the circulation system are controlled only by a color touch screen. Arc Melting 1. Tungsten electrode: tungsten needle Ø4mm, with water cooling pipe 2. Maximum adjustment travel distance of tungsten electrode: ≤380mm×300mm×50mm 3. Water-cooled crucible: Ø25mm in diameter, total 32 pcs 4. Maximum melting temperature: 3500℃ power supply 1. Voltage: AC 380V 50Hz 2. Output current: 15A-315A |

Product Weight | Weight: about 120kg |

Cautions | 1. High-purity Ar gas (5N) is required in the metal smelting process. 2. The smelting needs to be operated in a flowing protective gas environment, and a pressure reducing valve must be installed on the gas cylinder. 3. When the metal is smelting, please do not look directly, please wear goggles to observe. 4. If there are special size requirements for the glove box or different requirements for the number of smelting cavities, other size glove boxes made by our company can be selected. |

Optional Accessories | 1. Pressure-Reducing Valve |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics