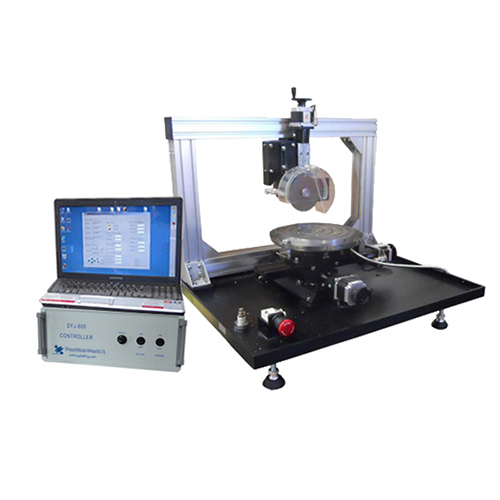

Precision CNC Cutting And Dicing Saw

Brand Shenyang Kejing

Product origin Shenyang, China

Delivery time 10 working days

Supply capacity 50 sets

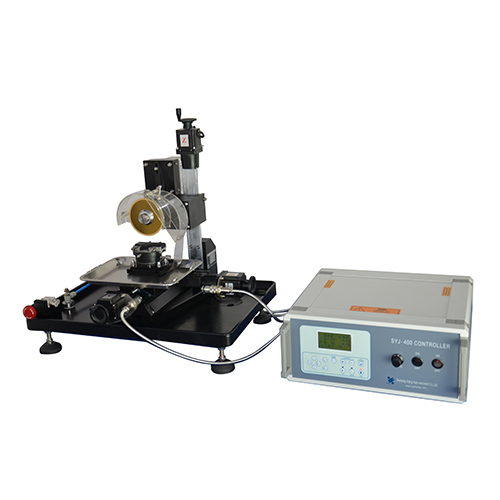

SYJ-400 CNC dicing saw is mainly suitable for dicing, grooving and cutting of various materials such as crystals, ceramics, glass, ore, metal, etc. It adopts a stepper motor, and can be computerized with a position accuracy of 0.01 mm. The sample cutting workbench can be rotated at 360°, and is equipped with a cross mount vise (with 90° positioning die to ensure the accuracy of cutting) and a vacuum chuck(Optional).

Main Features

Computerized control, allowing users to program sample cutting by themselves

Adopting large-torque AC brushless motor to drive the spindle through belt pulleys and adjusting rotating speed 0-3000rpm through speed regulating buttons

Choosing proper blade and blade clamp according to the size of material samples

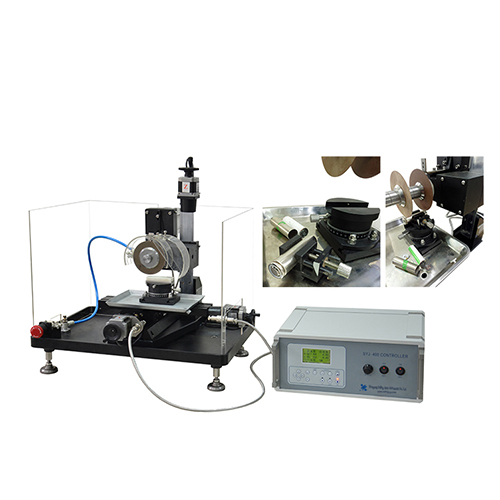

Equipped with a splash-protection cover and a throttle valve to control coolant flow

Technical Parameters

Product Name | SYJ-400 CNC Dicing / Cutting Saw | |

Product Model | SYJ-400 | |

Conditions for Installation | 1.This equipment is required to be used with a temperature of 0-45℃, and a humidity of 10-85%RH (at 25℃ no condensation) 2.There is no strong source and corrosive gas around the equipment. 3.Power supply:AC220V 50Hz 4.Water: The equipment is equipped with water inlet and outlet and corresponding water pipelines, which need to be connected to tap water and drainage by users. 5. Gas: N/A 6. Workbench: size 800mm×600mm×700mm, bearing 50kg or above 7.Ventilation: good ventilation environment, no special ventilation requirements | |

Major Parameters (Specifications) | 1. Power supply voltage: 110V/220V | |

2. Power of spindle motor: 180W | ||

3. Spindle speed: 0-3000rpm | ||

4. X-axis slide distance: 210mm | ||

5. Y-axis slide distance: 110mm | ||

6. Z-axis slide distance: 90mm | ||

7. X/Y/Z axis drive motor: high-precision stepper motor | ||

8. Stepper motor positioning accuracy: 0.01mm | ||

9. Max. Cutting depth: 50mm | ||

10. Workbench rotation: 360°±0.5° | ||

11. Sample plate size: 80mm×25.4mm | ||

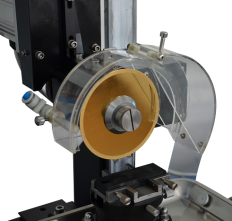

12. Blade size: Ø100mm×Ø12.7mm, Ø150mm×Ø12.7mm | ||

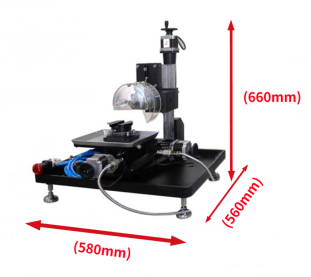

13. Dimension and weight · dimension: 580mm×560mm×660mm · weight: 39kg |

| |

Standard Accessories

No. | name | qty | picture |

1 | Blade Clamp | total 3 sets |

|

2 | Cross Mount Vise | 1 set | |

3 | Aluminum Plate | 2 pcs |

|

4 | Resin Bonded Ceramics (50×50×10mm) | 2 pcs | |

5 | Fully Sintered Diamond Blade (Ø100mm×Ø12.7mm×0.33mm) | 1 pcs |

|

6 | Electroplated Diamond Blade Ø100mm×Ø12.7mm×0.5mm | 2 pcs |

|

7 | Wax Bar | 4 pcs |

|

8 | Splash-Protection Cover | 1 set | |

9 | Goggles | 1 pair |

|

Optional Accessories

No. | name | functional type | picture |

1 | Edge Sintered Diamond Blade (Ø100mm×Ø12.7mm×0.33mm) | (optional) |

|

2 | Sintered Diamond Dicing Blade | (optional) | |

3 | Oilless Vacuum Pump | (optional) | |

4 | JXZ-25Y Coolant Circulating Tank (with Pump) | (optional) | |

5 | Heating Plate | (optional) |  |

Remarks and Warnings

· It is recommended that customers use anti-corrosion coolant during the cutting process to avoid rusting of the lead screw.

· Be sure to clean the machine after each use, especially clean the lead screw with lubricant to make sure that X, Y and Z axles can move freely without blocking or rusting.

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics