Experiment: to test the effect of UV ozone cleaning time on spin coating

Report of the Experiment

I. Experimental Purpose:

to test whether UV ozone cleaning can reach the effect of other cleaning methods and to test the effect of UV ozone cleaning time on spin coating

II.Experimental Equipment and Material:

Experimental Equipment: VTC-100 vacuum spin coater, VGT-1620QTD UV cleaner and UV ozone lamp (8W/pcs×3, total power 24W)

Experimental Material: φ50×1mm round glass substrate and green ink

III.Experimental Principle:

UV lamp decomposes organic molecules (pollutants) by producing high-intensity UV light of 185nm and 254nm. Light of 185nm can convert oxygen molecule O2 into active O3 ozone molecule. Light of 254nm simultaneously excites organic molecules on the surface, making it more easily absorbed and decomposed by ozone molecules. This photosensitive oxidation reaction process is continuous, under illumination of these two short-wave UV lights, ozone will continue to generate and decompose, producing more and more reactive oxygen atoms. Reactive oxygen atoms (O) with strong oxidation function oxidize with activated organic molecules to form volatile gases (such as CO2, CO, H2O, NO, etc.), which escape from the object surface, thereby completely removing the organic pollutants adhering to the object surface. In the production of LCD and OLED, light cleaning before applying photoresist, PI adhesive, directional film, chrome film and color film can greatly improve the wettability and the adhesion of the substrate surface.

IV.Experimental Process:

First, clean the surface of the glass substrate with UV wave for 10 minutes. The cleaning medium is alcohol. Then put the UV cleaned glass substrate under a UV ozone lamp for UV ozone cleaning and surface wettability improvement. The distance between the UV lamp and the glass substrate is 38mm. Then, spin coat the glass substrate cleaned by UV ozone for different times is rotated coating, and the parameters of film coating are step 1 1000rpm 5s for step 1, and 3000rpm 50s for step 2, and the amount of film liquid is 100μl each time. Observe the change of film morphology on the surface of the glass substrate after coating.

V.Experimental Data

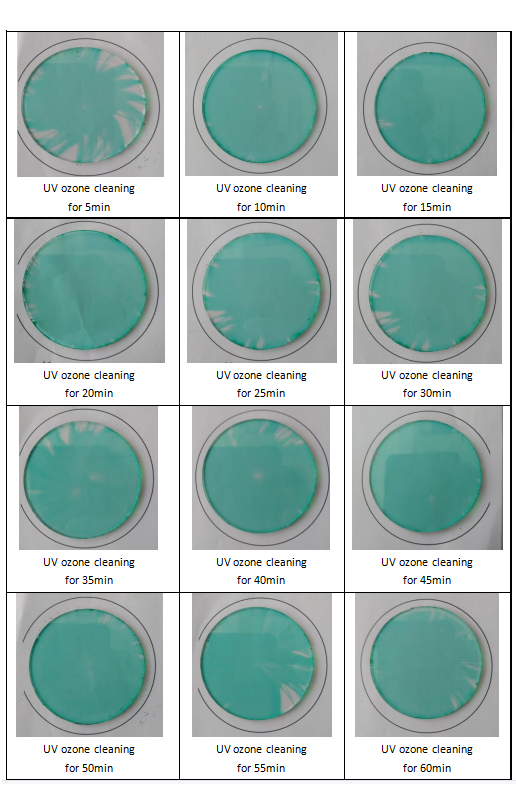

Experiment 1:

After UV ozone cleaning at 5min intervals, the substrate is coated with a film as shown in the figure below:

It can be seen that when the cleaning for over 10min, the wetting performance of the glass substrate surface changes significantly, and the film almost completely covers the surface of the glass substrate when coating for 10min, 15min, and 20min. Theoretically, the longer the cleaning time, the cleaner the substrate surface is cleaned, the better the wetting performance of the substrate surface, and the better the film coated on the substrate surface, but it can be seen from this experiment that the film on the substrate surface is incomplete whening coating for 25min, 30min, and 35min, and after that a complete film is coated with time prolonged. This behavior can occur for two reasons:

1.The inorganic or organic pollutants on the substrate surface aren’t completely removed before UV ozone cleaning, cannot be removed during UV ozone irradiation, so, the surface of the substrate is still unclean after twice cleaning, and a complete liquid film cannot be coated on the surface of the substrate.

2.During UV ozone irradiation, the decomposed organic matter on the substrate surface forms a dynamic balance for some certain period of time. The organic matter is completely decomposed, and the active O produced by the decomposition of ozone completely reacts with the organic matter to generate stable oxides which can volatilize. With the absence of active particles on the surface of the glass substratefor a period of time, the previously improved wetting performance of the surface of the substrate is reduced. So, a complete film cannot be obtained during this period of time. While ith the extension of UV light irradiation time, this dynamic balance is broken again, so that the wetting performance of the glass substrate surface is restored, and a complete film can be coated again.

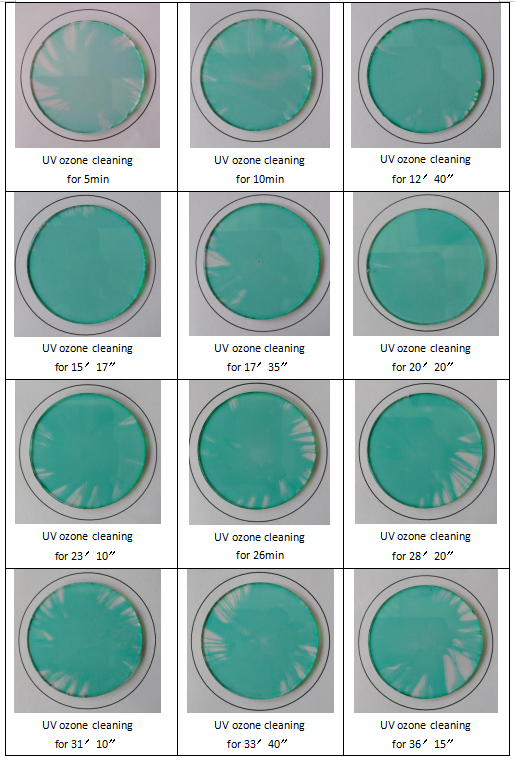

Experiment 2:

Continuously coat on the substrate and observe effect of coating time on film coating. It can be seen from the result of experiment 2 that the coating effect is the best when UV ozone cleaning for 10min to 23min. However, the coating effect is not good when UV ozone cleaning for 23min to 38min, during this period of time, a complete film cannot be coated. While with the irradiation time prolonged, the coating effect is somehow improved.

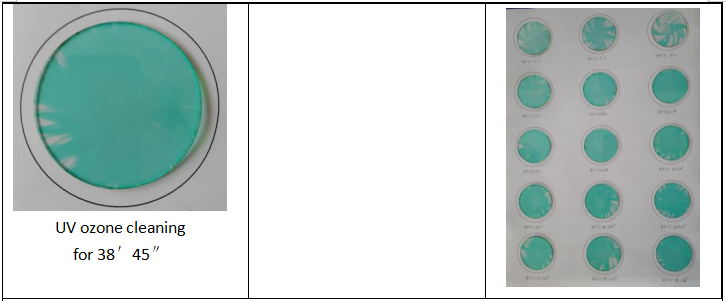

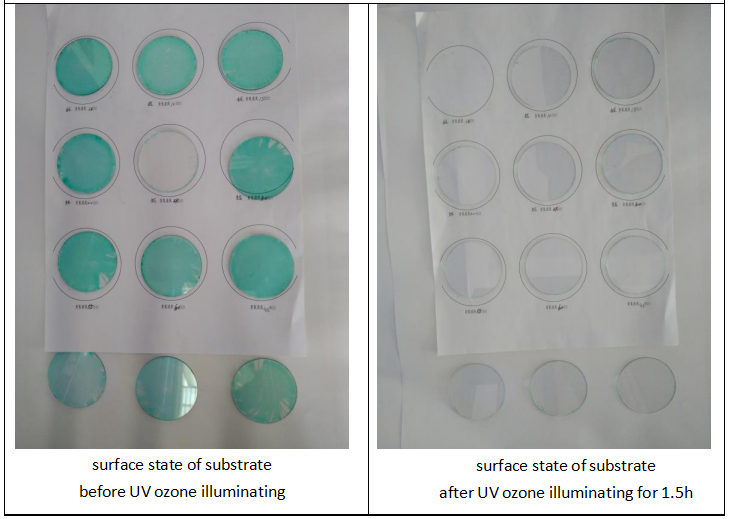

Experiment 3:

Put all the coated subtrates under the irradiation of UV ozone light for about 1.5h. After that, take out the substrates. It can be seen that the color on the substrate surface is almost removed. Based on this, it can be proved UV ozone can decompose the colored matter on the substrate surface, but there there are also some contaminants on the surface. There are two possibilities for this phenomenon. One possibility is that these contaminants are not organic and therefore cannot be decomposed by UV light, leaving them on the substrate surface. Another possibility is that there are too many contaminants taht require longer exposure time.

VI.Experimental Conclusion

1. UV ozone irradiation plays an obvious role in changing the wetting performance of the substrate surface.

2. There are obvious differences in the improvement of the surface performance of the substrate by different UV irradiation time, and it can be seen from experiment 1 and experiment 2 that the coating effect is the best when the irradiation time is between 10min and 25min.

3. UV ozone cleaning can remove the colored components on the substrate surface.

4. UV ozone cleaning operation is simple, no additional equipment is required, the process of substrate cleaning is shortened, saving experimental time, and multiple substrates can be cleaned at the same time.