Taking a Round Rod Sample on a Smelted Stainless Steel Block with a Sample Puncher

2023-07-06 13:41Experimental Material:

A φ25×9mm smelted stainless steel block

Due to the different lattice types of stainless steel materials, the hardness of ferritic and martensitic stainless steel is slightly lower than that of carbon steel, while the hardness of austenitic stainless steel is slightly higher than that of carbon steel. In general, stainless steel is a harder material.

Figure 1: smelted stainless steel block

Experimental Purpose:

to take a φ3.5×9mm round rod sample on a stainless steel block

Experimental Equipment:

SYJ-30QY sample puncher and hot glue gun

SYJ-30QY sample puncher hot glue gun

Figure 2: equipment used in the experiment

Experimental Consumables:

φ4mm sintered diamond drill bit, resin ceramic spacer block and hot glue bar

drill bit resin ceramic spacer block hot glue bar

Reasons for Selecting Equipment:

SYJ-30QY sample puncher is specially used for taking cylindrical or ring samples of solid materials, and can also be used for sampling crystals, ceramics, metals, glass, rocks, cores, plastics, PCB boards, refractories, composites, etc. The minimum sampling size of this machine is Ø3mm, which can be used for TEM sample preparation in the early stage.

Equipment Features:

1. Samplers of different specifications can be used to obtain cylindrical and annular samples of different sizes, and can also carry out drilling operations on materials.

2. The samples obtained are neat with high accuracy.

3. The Z axis is driven by a stepper motor, and the X and Y axes are manually adjusted.

4. The machine is equipped with a fast caliper and a cooling water tray.

5. The machine is easy to use, simple to operate and beautiful in shape, occupying small space, and is suitable for applications in laboratories.

Experimental Process:

In this experiment, to take a round rod sample from the metal block, the metal block must be fixed first, and paraffin wax or hot melt adhesive is often used in laboratories to fix samples. Paraffin wax usually can fix flat surfaces relatively firmly, while for uneven surfaces, the firmness of paraffin wax is relatively poor, because paraffin wax is soft and is easy to break after receiving forces. Therefore, in this experiment hot melt adhesive is selected to fix the sample. Insert the hot melt glue rod into a hot glue gun, switch on the hot glue gun for heating, when the the glue bar melts and viscous glue flows out, the sample can be bonde. The lower surface of the sample should be flattened as much as possible during the bonding process to facilitate sampling.

When sampling with SYJ-30QY sample puncher, the resin ceramic spacer pad that holds the sample is firmly stuck with a caliper on the sampling stage, and then adjust the sample machine so that the drill bit is moved above the sample. During the sampling process, the sample and the drill bit should be cooled with water to avoid the drill bit from being damaged because the temperature increases too high due to the friction between the drill bit and the sample. Excessive high temperature will melt the hot melt adhesive that holds the sample in place, causing the sample to fall off, which in turn is not conducive to the continuous sampling process. When cooling the sample and the drill bit, it should be noted that the cooling water need to be poured onto the drill bit and the sample at the same time, and the water flow should not be too fast, so as not to pour water outside of the sample puncher. The fixing method and position of the sample on the sampling stage is shown in Figure 4.

Figure 4: fixing position of sample on sampling stage

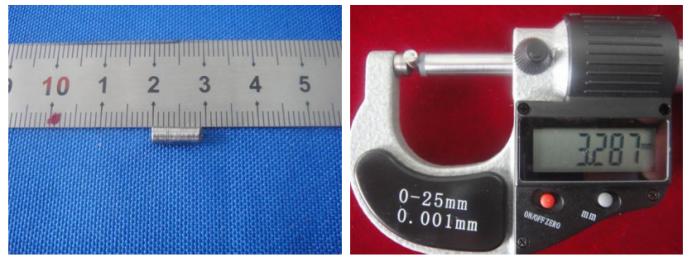

After fixing the sample and adjusting the drill bit position, sampling can be performed. As the stainless steel sample is relatively hard, the sampling speed should not be too fast. Otherwise, sampling may fail and at the same time the drill bit may be damaged. Therefore, the sampling speed should be slowed down. In this experiment, the sampling speed is set to 0.1mm/min. The sampling distance should be set slightly largher than the actual thickness of the sample, so as to ensure that a complete sample can be taken out. In this experiment, the sampling distance is set to 15mm. When adjusting the spindle speed, turn the spindle knob to the right for half a circle to get the required sampling speed. Start the sample puncher after setting parameters. When sampling, first switch on the spindle of the machine to let it rotate, and then start the control box to run the program. Otherwise, if running the program first, the drill bit will bump onto the sample, which will cause the spindle not to rotate and the drill bit or even the machine to be damaged. The morphology and size of the finished sample are shown in Figure 5. It can be seen that the finished sample is a round rod with a diameter of 3.3mm and a length of about 9mm. The actual diameter of the sample is slightly smaller than requirement. This is because there will be a certain amount of shaky movement with the rotation of the drill bit, which will make the actual size of the sample smaller. To get the right size sample, increase the size of the drill bit appropriately according to the shaking margin of the machine, or customize corresponding drill bits to obtain a sample with the desired size. It can be seen from Figure 5 that the size of the finished sample is uniform, which indicates that, the shaking margin is uniform and the downward travel speed is uniform as the drill is driven downward into the sample throughout the sampling process.

Figure 5: morphology and size of finished sample

Experimental Conclusion:

When sampling with SYJ-30QY sample puncher, the finished sample is a round rod with high accuracy. The sampling speed can be adjusted according to the material of the sample.