Diamond Wire Saws

Cutting principle of diamond wire saws:

A diamond wire saw is equipped with a spooler. The spooler reciprocates while rotating at a high speed, thereby driving the diamond wire to move repeatedly backwards and forwards. The diamond wire is tensioned by the tensioning wheel. In order to increase the cutting accuracy and the flatness of the cutting surface, a guide wheel will be installed to guide the cut[1]. The sample is continuously fed in the direction of the diamond wire on the workbench which is automatically controlled by the machine, or the sample is continuously fed in the direction of the workbench when the diamond wire is automatically controlled by the machine. In this way, grinding and cutting is continuously generated between the diamond wire and the sample so as to generate cutting motion.

Cutting advantages of diamond wire saws:

When non-conductive material needs to be processed by wire cutting, EDM wire saw is no longer applicable. At this time, the processing advantages of the diamond wire saws are revealed. Diamond wire saws are suitable for cutting both conductive materials and non-conductive materials (with less hardness than diamond wire). Therefore, diamond wire saws are widely used in cutting various metals and non-metals and composite materials, such as ceramics, glass, rocks, gems, jade, meteorites, monocrystalline silicon, silicon carbide, polycrystalline silicon, refractory bricks, epoxy boards , ferrite, PCB as well as building materials, dental materials, biological materials and biomimetic composite materials, etc., especially suitable for cutting various brittle materials with high hardness, high value and easy breakage[2-3].

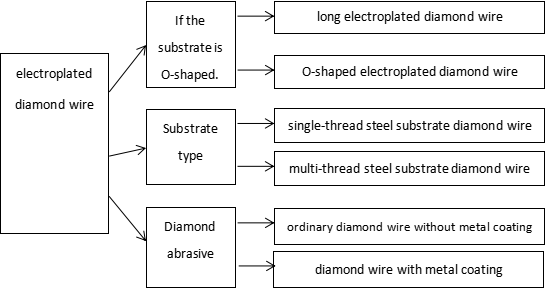

The diamond wires commonly used in diamond wire saws are mainly electroplated diamond wires.

1. Electroplated type: A linear superhard material tool is made by depositing a layer of metal (usually nickel and nickel-cobalt alloy) on the metal wire by electroplating, and consolidating diamond abrasive in the metal. The metal coating is the bond and the diamond abrasive is used for the cutting process.

At present, the most researched and applied diamond wires are single-thread steel substrate long diamond wire with a round cross-section and annular electroplated diamond wire. Electroplated long diamond cutting wire refers to the cutting wire formed by consolidating diamond abrasives onto a headed metal substrate by means of electroplating. The cross-section of commonly used substrates is circular, generally from 0.12 to 0.5 mm, and this type pf wire is mainly used for cutting silicon crystals and sapphire. The O-shaped electroplated diamond cutting wire refers to the cutting wire formed by electroplating diamond abrasive onto the O-shaped metal substrate. When this type of cutting wire is used, it is generally wound around several guide wheels for one-way circular cutting, and there is no need to change direction during the cutting process, so the cutting speed is high. The diameter of the O-shaped electroplated diamond wire welded by a single steel wire is generally no more than 1 mm, so the cutting kerf is small, and this type of wire is suitable for cutting relatively precious hard and brittle materials such as silicon crystal and sapphire. However, the technical requirements on heat treatment of the welded joints are relatively high, and the service life is relatively short. A single-thread steel wire is weaved into an O-shaped steel strand or an O-shaped wire rope by means of winding. The diameter of this type of cutting wire is generally difficult to be less than 1 mm, so the cutting kerf is wider. The cutting wire is not easy to break, and has a long service life, which is suitable for cutting graphite, composite non-metallic materials, etc. [4].

The diamond wires used on STX series diamond wire saws (manufactured by SHENYANG KEJING AUTO-INSTRUMENT CO., LTD.) are mainly electroplated diamond wires. At present, diamond wires with different diameters are applied: φ0.125mm, φ0.25mm, φ0.35mm and φ0.42mm. The wires can also be customized according to the actual needs of customers. The wire diameter tolerance of φ0.125mm and φ0.25mm diamond wires is ±0.02mm, while the wire diameter tolerance of φ0.35mm and φ0.42mm diamond wires is ±0.03mm. When cutting, the appropriate wire diameter can be selected according to the material, shape, size and actual cutting requirements of the sample. Generally, the diamond wire with a diameter of 0.35mm is suitable for cutting most materials.

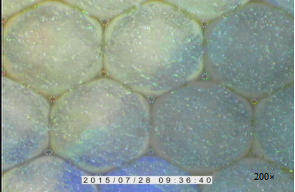

STX series diamond wire saws (manufactured by SHENYANG KEJING AUTO-INSTRUMENT CO., LTD.) are high-precision flexible cutting machines, which have the features of simple operation, As shown in Figure 1, being magnified 200 times under the microscope, the surface topography of the glass column (cut by STX-202A diamond wire saw) has excellent processing quality, perfect cutting surface and unbroken edges. Diamond wire saws are especially suitable for cutting crystals, ceramics, glass, honeycomb ceramics (car exhaust gas treatment carrier, thin-walled, fragile), metal, plastic, PCB, rock samples, mineral samples, refractory materials, jade, meteorites, composite materials, building materials, dental materials, biological and biomimetic composite materials, etc. However, diamond wire saws are generally not applied to metals with high toughness, because soft metal with high toughness are easy to stick to the blade when cutting, which will reduce the service life of the diamond cutting wire to a certain extent. The diamond wire saws manufactured by SHENYANG KEJING AUTO-INSTRUMENT CO., LTD. adopt aluminum profile structure, which is beautiful and light, and is not easy to rust. According to the size and shape of the samples, diamond wire saws can be divided into various models. Each model of the STX series diamond wire saws has both common features and its own characteristics and advantages. Customers can select the appropriate cutting machine according to the morphological characteristics of samples.

Fig 1: surface topography of glass column after being cut by STX-202A diamond wire saw