Ultrasonic Spray Pyrolysis Coater

MSK-USP-04C Ultrasonic Spray Pyrolysis Coater/Glue Sprayer uses a stepper motor and a microprocessor to control the volumetric pump to ensure accurate transmission of solutions through the infusion set and the continuity of ultrasonic spray process. An ultrasonic atomizer is used to prepare a thin micro-nano coating, and a stepper motor is used to control the atomizer to move in the X-axis and Y-axis directions, and the moving speed can be adjusted within a certain range to ensure the uniformity of coating on the substrate surface.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

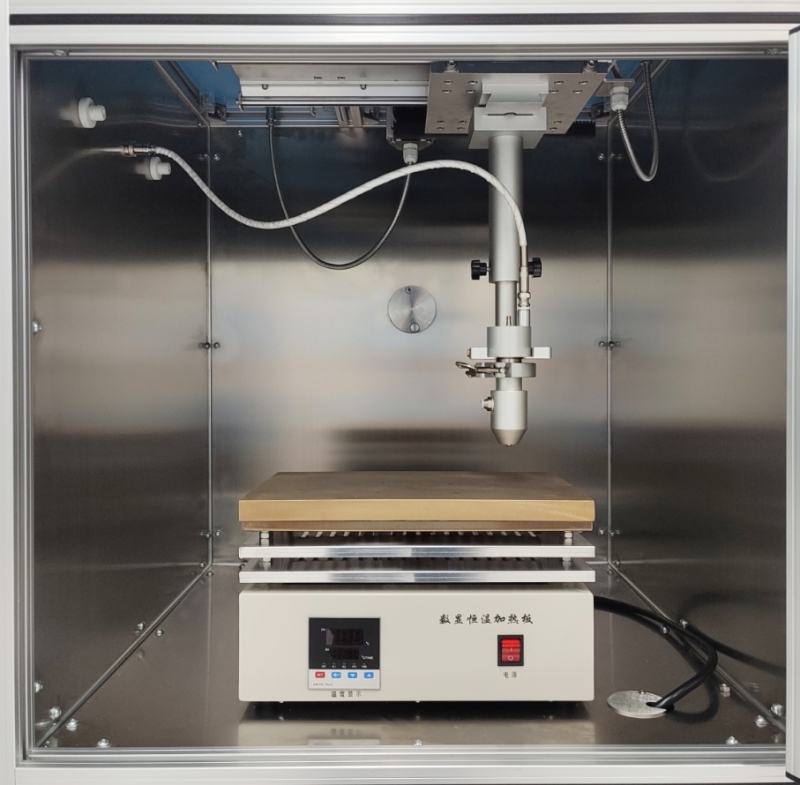

The MSK-USP-04C Ultrasonic Spray Pyrolysis Coating System (Spray Coater) utilizes a stepper motor and microprocessor to precisely control the volumetric pump, ensuring accurate solvent delivery and continuous ultrasonic spraying. A high-frequency ultrasonic atomizer produces fine micro- and nanoscale coatings, while the spray head—driven by a stepper motor—moves along the X and Y axes with adjustable speed to ensure uniform film deposition on the substrate surface.

The system features a heating platform that controls the substrate temperature to accelerate film drying. The platform can reach temperatures up to 500°C, meeting the requirements of most laboratory applications.

The spray pyrolysis coating method involves atomizing a precursor solution and spraying it onto a heated substrate, where the desired material structure forms upon solvent evaporation and decomposition. This method is particularly suitable for depositing oxide films and has a long history of use in transparent electrode fabrication. It is now widely applied in the preparation of perovskite solar cells.

Main Features

The atomization method is to spray the solution onto the substrate after atomization, so as to obtain the desired material structure. This material preparation method is particularly suitable for depositing oxides and has a long history of application in the preparation of transparent electrodes. Now this method is widely used in the preparation of perovskite solar cells.

Technical Parameters

| Product Name | MSK-USP-04C Ultrasonic Spray Pyrolysis Coater/Glue Sprayer | ||

| Product Model | MSK-USP-04C | ||

| Installation Conditions | 1. Temperature and Humidity: 10–85% RH (at 25°C, non-condensing); Temperature: 5–45°C. 2. Environment: The equipment should be installed away from strong vibration sources and corrosive gases, with at least 200 mm of clearance around it. 3. Water Supply: Not required. 4. Power Supply: Single-phase AC220V 50Hz, 16A, three-prong socket with proper grounding required. 5. Air Supply: Requires an air compressor or gas cylinder (with pressure regulator); working pressure: >0.4 MPa. 6. Workbench: Not required; floor-standing equipment with an installation area of at least 2 m². 7. Ventilation: The equipment must be connected to an exhaust duct. | ||

Main Parameters (Specification) | Injection pump

| · Pump Power Port: DC24V independent power adapter (standard configuration “Power Adapter” IN: AC100-240V 50/60Hz, OUT: DC24V 3.75A) · Pump Power: ≤50W · Injection Pump Size (Actuator): 250mm×65mm×50 mm · Injection Speed: 0.001–20 mm/min · Fine Adjustment Speed: 0.001–10 mm/min · Syringe Diameter: 0.04–30 mm · Standard Syringe Volume: 20 mL · Stroke Setting Range: 0.01–90 mm · Operation Control Mode: 4.3-inch touchscreen with independent settings (synchronized with main unit operation) | |

Ultrasonic Atomization

| · Power Supply Port: AC 220V 50Hz 10A, powered via main unit interlocked socket · Atomizing Nozzles: • CSA40-1 Mushroom Head – Wider spray diameter: 40 mm × 1 pc • CSA40-2 Cylindrical Tip – Narrower spray diameter: 20 mm × 1 pc · Ultrasonic Nozzle Frequency: 40 KHz ±10% · Maximum Ultrasonic Power: 200 W · Particle Size / Flow Rate: Particle size: 10–20 μm; Flow rate: 0.6 pl–4 mL/min · Viscosity / Solid Content: Viscosity ≤100 cps; Solid content ≤10% · Control Mode: Independently set or operated in synchronization with the main unit | ||

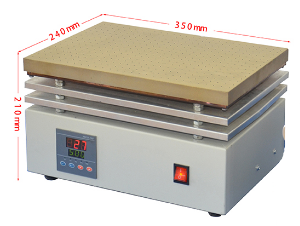

Heating Platform

| · Power Supply Port: AC 220V 50Hz 16A, powered via main unit interlocked socket · Cast Copper Heating Plate Size: 350 × 240 mm · Heating Range: Effective operating range: Room temperature – 500°C · Heating Power: 2.5 kW · Control Mode: Independently set or operated in synchronization with the main unit | ||

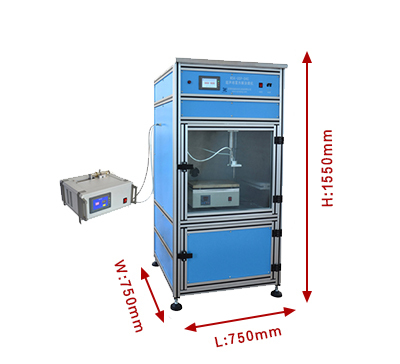

| Main Unit | · Power Supply Port: AC 220V 50Hz 16A · Total Power: 2.8 kW (excluding air compressor) · X-Axis Travel (Sample Length): 1–200 mm · Y-Axis Travel (Sample Width): 1–200 mm · X-Axis Speed Range: · Manual Control: 10–100 mm/s · Automatic Control: 10–800 mm/s · Y-Axis Speed Range: · Manual Control: 10–100 mm/s · Automatic Control: 10–100 mm/s · Layer Spacing: 1–100 mm · Z-Axis Manual Adjustment Range: 60 mm · Exhaust Port: Ø75 mm ·Control Mode: 4.3-inch touchscreen operation ·Overall Dimensions: 1550mm× 750mm × 750 mm ·Total Weight: 120 kg |  | |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics