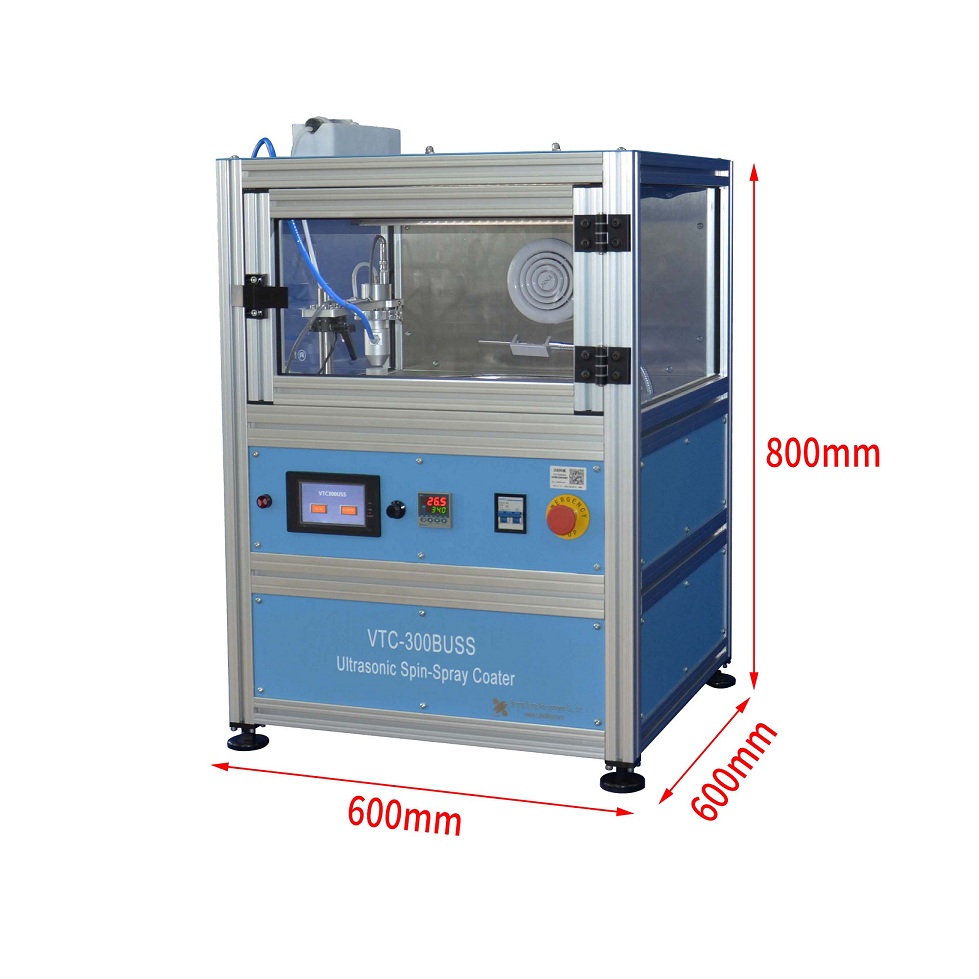

Ultrasonic Spin-Spray Coater With Heater And Fume Hood

VTC-300BUSS Ultrasonic Spin-Spray Coater is an all-in-one film preparation equipment with box structure that combined ultrasonic atomization, liquid injection and spin coating functions. The diameter of absorbable substrates (of VTC-300BUSS ultrasonic spin-spray coater/glue sprayer) can be up to 12" (300mm).

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

The VTC-300BUSS Ultrasonic Atomizing Spin Coater / Spray Coater combines the advantages of both spin coating and spray coating technologies. This system converts standard 50–60 Hz AC power into a high-power, high-frequency (15 kHz–100 kHz) electrical supply for the ultrasonic atomizing head, which then transforms electrical energy into mechanical vibrations. These vibrations atomize the solution into fine droplets, enabling dense and uniform liquid-phase coatings on large substrates.

It is suitable for a wide range of applications, including low-temperature precipitation (e.g., for RF/microwave ferrite deposition), polymer coatings, powder and composite coatings, and coatings on patterned or uneven substrates. The system allows precise control of the solution stoichiometry, spray rate, and droplet size, and it supports both independent spin and independent spray operation modes.

The VTC-300BUSS features a fully enclosed chamber design, which effectively prevents external environmental factors from interfering with the coating process. The rear exhaust system safely removes harmful gases through an external ventilation pipeline. The liquid delivery system, driven by a stepper motor and microprocessor-controlled volumetric pump, ensures accurate solution feed (with optional solution heating).

The ultrasonic atomizer, mounted on a swingable support arm, guarantees coating uniformity by evenly depositing fine mist particles onto the substrate, resulting in the desired material structure. It enables the preparation of thin micro- and nanoscale films with excellent consistency.

The system supports substrates up to 12" (305 mm) in diameter and includes an infrared radiation heating module for rapid film drying via substrate temperature control.

This material preparation technique is especially suitable for oxide deposition and has long been used in transparent electrode fabrication. In recent years, it has been widely applied in the production of perovskite solar cells.

Main Features

1. It is an all-in-one film preparation equipment with box structure that combined ultrasonic atomization, liquid injection and spin coating functions.

2. Infrared heating method is adopted, and the heating speed is fast.

3. This equipment needs to be used with a vacuum pump and an air compressor. The vacuum pump adsorbs and fix samples, and the air compressor enhances the directionality of spray and reduces the spilling of the spray. (The air compressor is not standard configuration.)

4. The liquid injection system can be equipped with single channel or multi channels.

5. The equipment is equipped with an exhaust system, which can remove the steam and peculiar smell of the liquid in the box.

6. A gas filter device can be added to filter the exhausted toxic and harmful gases and reduce pollution to the environment.

7. The equipment is equipped with an infrared alignment mechanism, which can determine the starting position of spraying through infrared rays.

8. LED lighting system is used in the box, which has a longer service life and brighter light.

9. There is a movable thermometer in the box, which can accurately measure the temperature of each point in the box.

10. The number of ultrasonic atomizing nozzle stations can be increased up to 4 stations.

Technical Parameters

Product Name | VTC-300BUSS Ultrasonic Spin-Spray Coater | ||

Product Model | VTC-300BUSS | ||

| Installation Conditions | 1. Temperature and Humidity: 10–85% RH (at 25℃, non-condensing); Temperature: 0–45℃. 2. Environment: The equipment should be placed in an area free from strong vibrations and corrosive gases. 3. Water: Not required. 4. Power Supply: Single-phase AC220V 50Hz 16A, with reliable grounding. 5. Gas: ① Vacuum (vacuum pump) with an exhaust flow rate not less than 70 L/min. 6. Worktable: No special requirements. 7. Ventilation: No special requirements. | ||

Main Parameters (Specification) | Rotating host 1. Sample tray (suction cup + card): Polypropylene vacuum suction cup: φ203 mm, upper limit of adsorption substrate diameter: φ305 mm 2. Operation mode: single direction counterclockwise operation 3. Spindle speed: 100-3000rpm effective 4. Speed stability: ±2% 5. Swing arm swing angle: 0-60° Recommendation: 8 inches (φ203) set angle 45°, 12 inches (φ305) set angle 60° 6. Swing arm speed: 1-20°/s 7. Atomizing nozzle: cylindrical tip: narrower spray diameter ~20mm 1 pc Mushroom head: wider spray diameter ~40mm 1 pc 8. Ultrasonic nozzle frequency: 40KHz±10%: amplitude power gear: 1, 2, 3 Adjustable gear 9. Particle size: 10-20um 10. Flow rate: 0.6pl-4ml/min 11. Viscosity: ≤100cps 12. Solid content: ≤10% 13. Fluid viscosity range: 1-50mpa.s (cP) 14. Recommended compressed air range for aqueous solution: ~2psi 15. Ultrasonic power: 200W 16. Heating method: infrared heating lamp: radiation baking 17. Heating temperature: RT-50℃ 18. Heating power: 2kW 19. Exhaust port: φ100 (can be connected externally: filter other gases in the box) 20. Host control mode: PLC programmer + touch screen + knob stepless speed regulation 21. Host total power: 2.5kW 22. Host power supply port: AC220V 50Hz 16A | ||

Injection pump system 1. Dimensions: 250mm×65mm×50 mm 2. Injection speed: 0.001-20 mm/min 3. Fine-tuning speed: 0.001-10 mm/ min 4. Syringe diameter: 0.04-30 mm 5. Standard needle volume: 20ml 6. Stroke setting range: 0.01-90 mm 7. Pump power: ≤50W 8. Pump power supply port: DC24V (standard "power adapter" IN: AC100-240V 50/60Hz OUT: DC24V 3.75A) | |||

Product Dimension | · Product Specifications: · Outline Dimension: 600mm×600mm×800mm · Total Weight: 100 kg |

| |

Optional accessories:

| No. | Name | Functional category | image |

| 1 | Multi-channel(heatable) liquidsupply system | Optional | - |

| 2 | Silent Oil-free AirCompressor | Optional | - |

| 3 | Cleaning machine: (1)Plasma cleaningmachine.PCE-6small plasmacleaning machine.PCE-6V smallplasma cleaning machine (2) UV ozonecleaning machine.PCE-22 UV ozonecleaning machine | Optional | - |

| 4 | Film thickness meter: TFMS-IV series compact high-precision reflective film thickness meter, SGC-10 thin film thickness gauge | Optional | - |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics