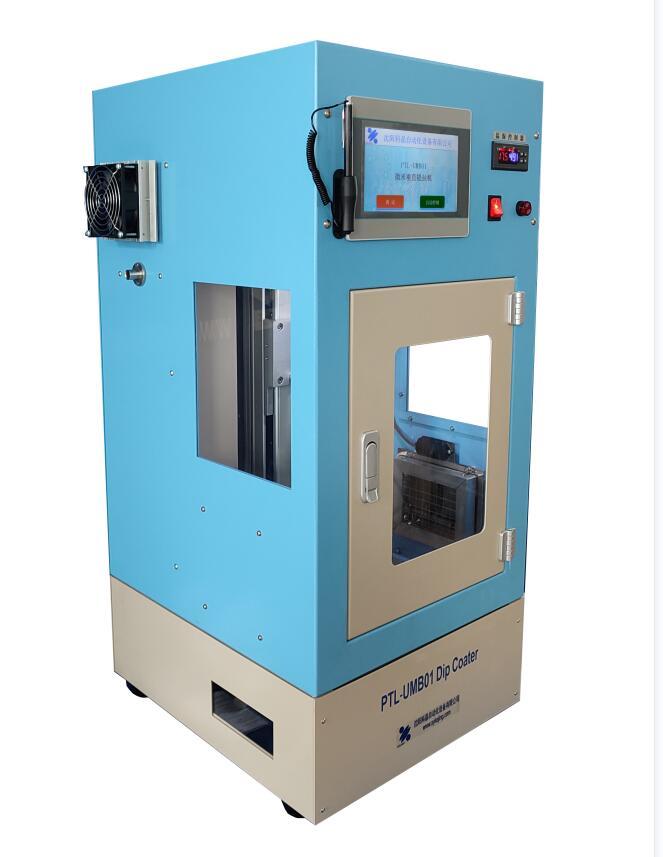

Servo Micron Grade Thermostatic Dip Coater

PTL-UMB01 Servo Micron Grade Thermostatic Dip Coater is designed for dipping the film in the liquid phase. By coating the substrate in the loading cup for a certain time and then pulling it out vertically, the film grows on the surface of the sample in the liquid phase.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The PTL-UMB01 Servo Micron Dip Coater is a micron-level precision instrument designed for dip-coating experiments in liquid-phase deposition. It is widely used in the field of thin-film material liquid-phase growth and is an essential tool for universities, research institutes, and laboratory applications in enterprises.

The system adopts a human-machine interface with programmable control and uses a closed-loop system to precisely drive the actuator with a high-precision servo motor, ensuring smooth and accurate lifting operations.

Its working principle is to vertically immerse the sample into the liquid-phase thin-film material, and after a preset dwell time, withdraw it at a uniform speed for drying, thereby forming a uniform film of specific thickness on the sample surface.

Main Features

1. Easy Operation: Equipped with a 7-inch color touch screen, providing an intuitive interface suitable for beginners.

2. High-Precision Control: A PLC controller in closed-loop mode drives the servo motor and precision linear module as the lifting mechanism, ensuring smoother and more accurate operation.

3. Additional Functions: Features heating and auxiliary dehumidification functions, making it suitable for a wider range of applications.

4. Space Optimization: Compact design with high cost-performance ratio, saving valuable laboratory space.

Technical Parameters

Product Name | PTL-UMB01 Servo Micron Grade Thermostatic Dip Coater |

| Product Model | PTL-UMB01 |

| Mounting Conditions | 1.This equipment is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 2. Water: N/A 3. Power Supply: Single-phase AC 220V ±7%, 50/60Hz, must have good grounding 4. gas: N/A 5. Workbench: size 800mm×600mm×700mm, bearing more than 200kg 6. Ventilation device: no need |

Major Parameters (Specifications)

| 1. Rated working voltage: AC220V 50/60Hz 2. Rated total power: 800W 3. Type: Programmable – Constant temperature 4. Drive motor: High-precision servo motor 5. Lifting speed setting range: · Manual: 10 μm/s ~ 8000 μm/s, resolution 1 μm · Automatic: 1 μm/s ~ 8000 μm/s, resolution 1 μm 6. Drying time: 1 ~ 999 s 7. Lifting stroke: 1 ~ 220 mm 8. Lifting cycles: 1 ~ 20 times 9. Dwell time: 1 ~ 999 s 10. Effective immersion depth: · Recommended ≤135 mm · Substrate: 75 mm × 25 mm × 2.5 mm · Immersion depth ≤60 mm 11. Substrate clamping size: · With standard accessories: Beaker 150 mL (φ60 × H80 mm); Substrate: 75 mm × 25 mm × 2.5 mm (2 pieces simultaneously) · Maximum recommendation: Beaker 3000 mL (φ150 × H240 mm); Substrate: 170 mm × 140 mm × 2.5 mm (single piece) · Note: Actual clamping size depends on container size and immersion depth. 12. Maximum lifting load: ≤1000 g 13. Main control/display: 7-inch color touchscreen 14. Temperature range: RT (room temperature) ~ +50 ℃ (max) 15. Humidity range: With auxiliary dehumidification function (subject to ambient humidity) 16. Temperature/humidity display & setting: Independent digital meters (dual-digit display / four-button setting) 17.Heating rated power: 300W × 2 18. Product Specifications: · Overall dimensions: 480 mm × 460 mm × 880 mm · Equipment weight: ≈60 kg |

Standard Accessories

No. | name | qty | picture |

1 | Coating fixture | 1 set | - |

| 2 | Liquid tank | 1 pcs | - |

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics