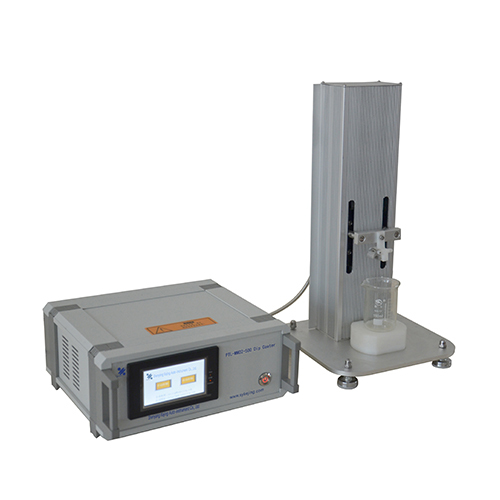

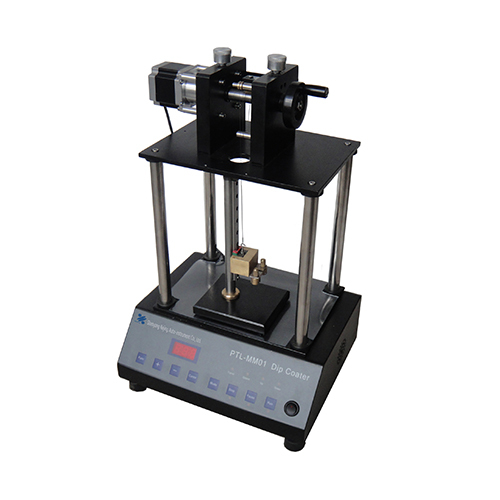

PLC Controlled Precision Dip Coater (1-500 mm/min)

PTL-MM02-500 Program-Controlled Vertical Dip Coater is a precision equipment specially designed for the study of liquid growing films of substrates. The film is grown by vertically pulling the sample that is dipped in liquid coating material. The pulling speed, the dipping time, the speed of the sample entering the liquid, the cycle times of the sample coating, and the drying time of the sample can be controlled by the control system.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The PTL-MM02-500 Programmable Vertical Dip Coater is a precision instrument designed for studying thin film growth on substrates in liquid phase. By vertically lifting samples immersed in liquid, thin films are formed on the surface. The system uses a high-precision stepper motor with subdivided driver control to ensure stable and accurate lifting speed. Parameters such as lifting speed, immersion time, dipping speed, coating cycles, and drying time can all be precisely set through the control system. Equipped with a high-precision speed control system and a touch-screen interface, the coater enables fully automatic process control. Compact in size and easy to operate, it is an ideal choice for laboratories and small-scale production workshops to coat larger samples at room temperature.

Main Features

1. This machine is equipped with a high-precision speed control system.

2. Parameters are set via a touch screen.

3. The entire process is fully automated.

4. CE certified.

Technical Parameters

Product Name | PTL-MM02-500 Programmable Vertical Dip Coater |

Product Model | PTL-MM02-500 |

Installation Conditions | This equipment is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: N/A 2. Electricity: AC220V 50Hz, must have good grounding 3. gas: N/A 4. Workbench: size 800mm×600mm×700mm, bearing more than 200kg 5. Ventilation device: no need |

Main Parameters (specification) | 1. Power supply: 220V (50Hz)/110V(60Hz) 2. Sliding (up and down) speed: 1mm/min-500mm/min(integer) 3. A high precision stepper motor is adopted. 4. Substrate size: 75mm (length) × 25mm (width) × 2.5mm (thickness) 5. pulling load: ≤100g 6. Effective dipping length: 60mm 7. Dipping and drying time setting: 1-999s |

cautions | 1. The process of film growing of sample surface is very delicate work. When installing and removing of the substrates, the growing film surface cannot be touched. 2. The substrate must be left with a head (6-10mm). For example, the film 50mm and the length of substrate is 56-60mm. If the head is not reserved, a special fixture can be purchased to make the substrate dipped completed into the liquid, i.e., a head is not required. This fixture can only hold one substrate. 3. If there are special requirements for the machine (speed, travel distance, substrate size, anti-corrosion, etc.), it can be specially designed for customers. |

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Power Cord | 1 pcs | - |

| 2 | Fixture | 1 pcs | - |

| 3 | Beaker Holder | 1 pcs | - |

| 4 | Control Box | 1 pcs | - |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics