PLC Controlled Precision Dip Coater (1-200 mm/min)

PTL-MM02-200 Program-Controlled Vertical Dip Coater is a precision equipment specially designed for the study of liquid growing films. The film is grown by vertically pulling the sample that is dipped in liquid coating material. Larger samples can be coated, and the size of samples can reach 310mm×260mm with thickness of 1mm-5mm.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

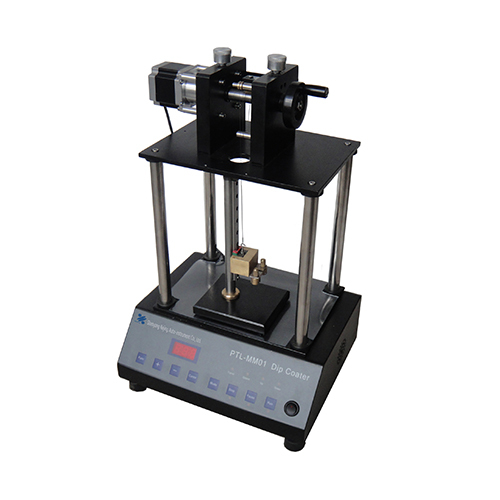

The PTL-MM02-200 is a millimeter-level precision dip-coating system, specially designed for thin film growth in liquid phase under ambient conditions. It is widely applied in the field of thin film material preparation.

This model is equipped with a PLC-based programmable control system and adopts a high-precision stepper motor with screw-drive mechanism to achieve smooth and accurate vertical motion. Using the vertical dip-coating method, the substrate is immersed in the liquid-phase film solution for a preset duration and then lifted at a constant speed. After natural drying at room temperature, a uniform thin film layer is formed on the substrate surface.

Featuring a compact structure, user-friendly operation, and convenient mobility, the PTL-MM02-200 is an ideal solution for universities, research institutes, and laboratory applications in the field of thin film fabrication.

Main Features

1. Equipped with a 4.3-inch color touchscreen with a simple and intuitive interface, suitable for beginners.

2. Compact size and cost-effective design, saving laboratory operating space.

3. Controlled by a PLC system with a high-precision stepper motor drive, ensuring smooth operation and high accuracy.

Technical Parameters

| Product Name | PTL-MM02-200 Programmable Vertical Dip Coater | |

| Product Model | PTL-MM02-200 | |

| Installation Conditions | 1. Power supply: Single-phase AC100–240V, 50/60Hz, A 10A circuit breaker must be installed at the front end. 2. Site environment: To be used at a temperature of 25℃ ±15℃ and humidity of 55%Rh ±10%Rh. | |

Main Parameters (Specification) | 1. Rated Power of Lifting Unit: 50W 2. Operating Voltage of Lifting Unit: DC24V 3.75A (Standard: AC100~240V Power Adapter) 3. Type: Programmable – Constant Temperature Model (with temperature-controlled chamber) 4. High-precision Stepper Motor: Drive motor 5. Speed Range: 1~200 mm/min (adjustable in 1 mm increments) 6. Immersion Dwell Time: 1~999 s (adjustable in 1 s increments) 7. Baking Dwell Time: 1~999 s (adjustable in 1 s increments) 8. Lifting Stroke: 1~270 mm (adjustable in 1 mm increments) 9. Lifting Cycles: 1~20 times 10. Sample Substrate Size: Max. (L) 310 mm × (W) 260 mm × (T) 1~5 mm 11. Effective Immersion Depth: ≤200 mm 12. Maximum Lifting Load: ≤5.5 kg 13. Solution Tank Material: White acrylic 14. Solution Tank Dimensions (Inner): (L) 340mm × (W) 50mm × (H) 280mm 15. Display & Control: 4.3-inch color touchscreen | |

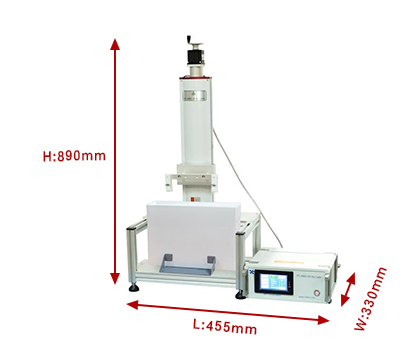

16. Product Specifications: · Dimensions:455mm×330mm×890mm · Net Weight:≈18kg |  | |

Standard Accessories

| No. | Name | Quantity | Image |

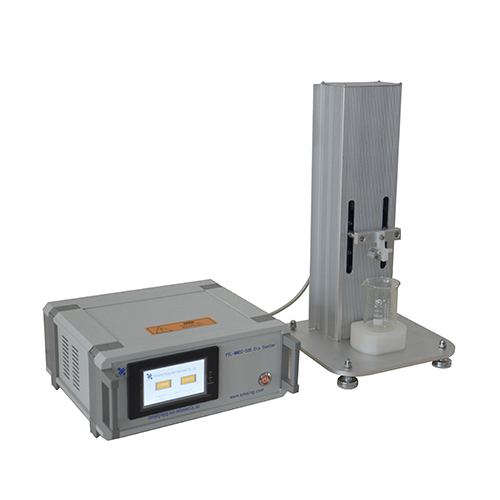

| 1 | Control Box | 1 pc | - |

| 2 | Solution Container | 1 pc | - |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics