Programmable Dip Coater ( Bridgman ) With Atmosphere Control

PTL-HT High Temperature Dip Coater is widely used in the study of various high-temperature pulling and coating. The heating furnace tube can provide a pulling and coating temperature of up to 1000℃. PTL-HT high temperature dip coater is especially suitable for materials that grow thin films at high temperatures, such as ceramic thin films, crystal thin films, battery material thin films, and special nano thin films.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

The PTL-HT High-Temperature Pull-Up Coating Machine is widely used for high-temperature pull-up coating research. Samples are fixed below the pull-up wire and lowered into the loading tray beneath the furnace tube, where they are immersed in liquid-phase film materials for a set period. The samples are then pulled back into the furnace tube for heating, allowing the film to rapidly solidify.

The heating furnace tube provides a pull-up coating environment with temperatures up to 1000℃. The machine is standardly equipped with pull-up wires suitable for environments up to 800℃. For operation in the 800–1000℃ range, custom pull-up wires or customer-supplied wires are required.

The PTL-HT is especially suitable for high-temperature film growth materials, such as ceramic films, crystalline films, battery material films, and special nanofilms. It meets the future development needs of high-temperature film formation technology. The machine features simple operation and easy cleaning, making it widely used in laboratories of universities, research institutes, and enterprises.

Main Features

1. Provides a high-temperature environment up to 1000℃, suitable for coating special materials; standard pulling wires are rated for ≤800℃, higher temperatures require customization.

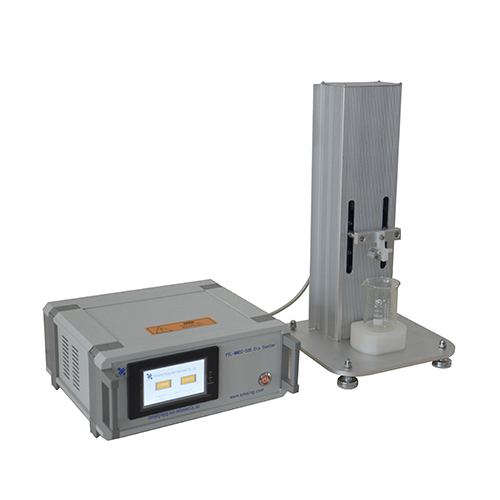

2. Can operate under inert gases (N₂, Ar) or oxidizing atmospheres.

3. Features three independent temperature zones, each with individually adjustable pulling speed.

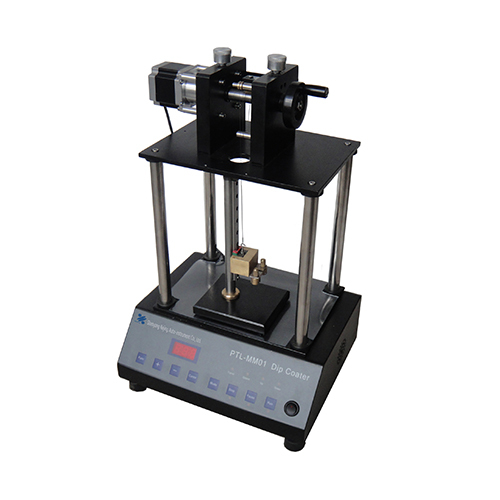

4. PLC-controlled high-precision stepper motor with suspended wire transmission for vibration reduction.

5. Equipped with a 4.3-inch color touchscreen, intuitive interface, easy operation.

Technical Parameters

Product Name | PTL-HT High Temperature Dip Coater | |

Product Model | PTL-HT | |

Installation Conditions | 1. Power supply: Single-phase AC220V 50/60Hz, with a 16A air switch installed upstream. 2. Operating environment: Temperature 25℃±15℃, humidity 55%Rh±10%Rh. | |

Main Parameters (Specification) | 1. Pulling unit operating voltage: DC24V 3.75A (standard: AC100~240V power adapter) 2. Pulling unit rated power: 50W 3. Type: Programmable – High-temperature model (with high-temperature furnace) 4. Drive motor: High-precision stepper motor 5. Speed setting range: Three-stage operation, each stage speed independently adjustable, 1–200 mm/min 6. Baking/holding time: 1–999 s 7. Total travel: Low-temperature zone + High-temperature zone + Cooling zone = 620 mm 8. First stage travel (Low-temperature zone): fixed at 236 mm 9. Second stage travel (High-temperature zone): fixed at 150 mm 10. Third stage travel (Cooling zone): fixed at 234 mm 11. Effective dipping length: 60 mm 12. Maximum pulling load: ≤200 g 13. Sample substrate size: L75 mm × W25 mm × D1–4 mm 14. Display & control: 4.3-inch color touchscreen | |

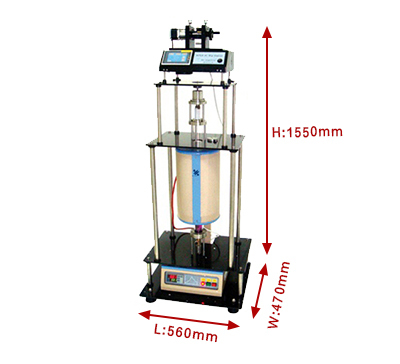

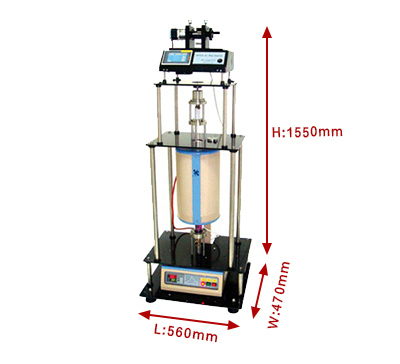

15.Product Specifications: · Dimension: 560mm×470mm×1550mm · Overall weight: ≈50 kg (including high-temperature furnace) |

| |

16.High-Temperature Furnace Technical Specifications: · Operating voltage: Single-phase AC220V 50/60Hz · Rated power: 1.5kW · Maximum heating temperature: 1100℃ · Rated heating temperature: 1000℃ · Usable temperature range: RT (room temperature) ~ +800℃ (with standard pull wire) · Recommended heating rate: 10℃/min · Temperature control accuracy: ±1℃ · Temperature control/set method: Intelligent temperature controller (multi-stage temperature control) · Thermocouple: Type K · Furnace chamber size: Φ80mm × 330mm · Furnace tube specifications: Φ50mm (outer diameter) × Φ45mm (inner diameter) × 600mm (length) | ||

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Sample Holder | 1 pcs | - |

| 2 | Beaker | 2 pcs | - |

| 3 | High Temperature Pulling Wire | 3 pcs | - |

Optional Accessories

| No. | Name | Function Category | Image |

| 1 | Special Pulling Clamp | Optional | - |

| 2 | Special High Temperature Pulling Wire (800-1000℃) | Optional | - |

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics