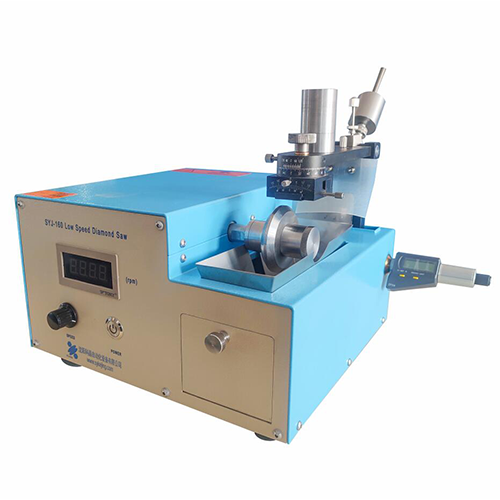

Precision Cutting Saw

1. SYJ-210 Variable Speed Automatic Precision Saw is specially designed for market demand.

2. The up and down movement of the Variable Speed Automatic Precision Saw expands the design space of the fixture, making it possible for multiple fixtures to share one machine and cut workpieces stably and reliably.

3. The Variable Speed Automatic Precision Saw is equipped with a safety protection interlocking device. When the protective cover is not closed, the main motor cannot be started. Only when the protective cover is closed, the main motor can be started.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Introduction of precision circular saw:

SYJ-210 automatic precision chop saw is designed for market demand and is widely used in colleges and universities, research institutes. Variable Speed Precision Diamond Saw is suitable for high-speed cutting of metals, ceramics, glass, rocks, ores, concrete and organic materials.

Variable Speed Precision Diamond Saw is equipped with a high-precision control system to ensure accurate cutting and is an ideal tool for material analysis. The fixture can be customized according to customer needs. The innovative saw blade lifting design expands the fixture space, realizes the sharing of multiple fixtures, and improves processing stability and reliability.

In addition, the Variable Speed Precision Diamond Saw is equipped with a safety protection interlocking device. When the protective cover is not closed, the main motor cannot be started to ensure safe operation. At the same time, the front panel is equipped with an emergency stop button, which is convenient for quickly cutting off the power supply in abnormal situations and effectively protecting the safety of operators.

Advantages of precision chop saw:

1. The precision circular saw can be adjusted steplessly, providing high torque output, ensuring a smooth and efficient cutting process, and adapting to the needs of different materials.

2. The precision circular saw is equipped with a large-size color touch screen with a simple interface, intuitive operation, and precise adjustment of various parameters.

3. The X and Y axes are driven by high-precision stepper motors to achieve stable and accurate positioning and movement.

4. The cooling circulation system is configured to effectively reduce the heat generated by the precision circular saw during cutting and extend the service life of the Variable Speed Automatic Precision Saw.

5. The precision circular saw has an infrared tool setting function, which uses infrared rays to accurately set the cutting starting point and improve cutting accuracy.

Variable Speed Automatic Precision Saw main features:

1. Variable Speed Precision Diamond Saw has stepless speed regulation, large torque and smooth operation.

2. Variable Speed Precision Diamond Saw large-size color digital display touch screen, parameters can be adjusted accurately

3. Variable Speed Precision Diamond Saw X-axis and Y-axis are driven by stepper motors.

4. Variable Speed Precision Diamond Saw is equipped with a coolant circulation system.

Demonstration of the operation of the precision chop saw:

Precision Circular Saw Technical Parameters:

Product Name | SYJ-210 Precision Chop Saw | |

Product Model | SYJ-210 | |

Installation Conditions Of Precision Chop Saw | 1. Temperature and humidity:Relative humidity 10-85%RH (at 25℃ without condensation) Temperature:0-45℃. 2. There are no strong earthquake sources and corrosive gases around the equipment. 3. Power supply:AC220V 50Hz national standard three-pole 16A socket, which must have a good ground wire. 4. Cooling water:precision chop saw is equipped with an upper water outlet and a lower water outlet. You need to connect tap water and drainage (circulating water tank) yourself. 5. Air source:No need for standard equipment. 6. Workbench: Recommended size:800mm×750mm×700mm, load-bearing ≥150kg 7. Ventilation device:good ventilation environment, no special ventilation device requirements are required | |

Main Parameters (Specification) | 1. Power supply port: AC220V 50Hz 16A 2. Total power: 2.1kW (including water pump output) 3. Spindle speed: effective value:2000~5000rpm, infinitely adjustable speed. 4. Spindle drive motor: variable frequency AC220V 1.3kW 5. Y-axis skateboard stroke:200mm 6. Y-axis movement speed: 0.05-40mm/min 7. Y-axis stage size:L254×W200mm 8. X-axis skateboard stroke: 70mm 9. X-axis movement speed: 1-200mm/min 10. X-axis stage size: L150×W200mm 11. X/Y axis drive motor: high-precision stepper motor 12. Stepper motor positioning accuracy:0.01mm 13. Saw blade lifting distance: 60mm 14.Maximum cutting thickness of precision circular saw:Y-axis platform:80mm, X-axis platform:50mm 15. Saw blade size: outer diameter:Ø200mm,inner diameter: Ø25.4mm or Ø32mm 16. Host control mode:touch screen + PLC programming control | |

17. Overall dimensions: L670mm×W690mm×H470mm Net weight:≈90kg |  | |

| About Precision Chop Saw Remark:This Variable Speed Automatic Precision Saw can customize various non-standard fixtures according to customer needs. | ||

| Compliance | CE Certified, UL or CSA certification is available at extra cost. | |

Precision Circular Saw Standard Accessories:

S/N | Name | Qty | Picture |

1 | Blade clamp (Ø32mm、Ø25.4mm) | total 2 sets | |

2 | Resin ceramic block | 2 pcs |

|

3 | Edge sintered diamond blade φ200×φ25.4×1.0mm | 1 pcs |

|

4 | Silicon carbide blade φ200×φ32×1.2mm | 2 pcs |

|

5 | Corundum blade φ200×φ32×1.2mm | 2 pcs |

|

6 | Wax bar | 10 pcs |  |

Precision Circular Saw Optional Accessories:

S/N | Name | Functional Type | Picture |

1 | JXZ-25Y automatic filter circulating water tank | (optional) |

|

2 | SYJ-200 special tooling series | (optional) |  |

Notes and warnings when using a precision chop saw:

· It is recommended that customers use anti-corrosion coolant during cutting with precision chop saw to prevent the screw from rusting.

· After each use of the precision chop saw, please clean the machine, especially the screw, and add lubricant after each use. Make sure the X and Y axes move freely without getting stuck or rusting.

Precision Chop Saw Warranty:

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Company Strength:

Our company is a professional provider of new material research and development solutions, professional laboratory material sample preparation complete solutions, and a domestic equipment manufacturer in the field of advanced materials research!