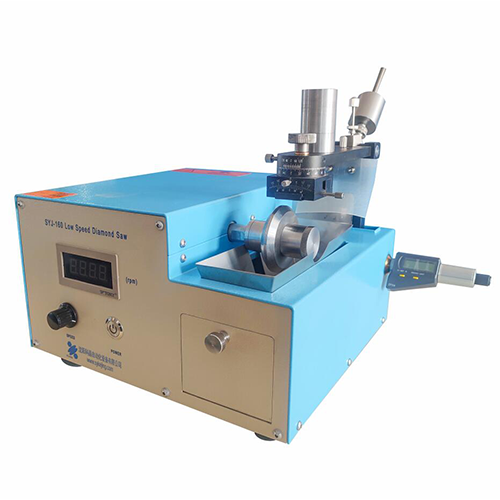

Low Speed Diamond Saw With 6" Cutting Blades

1. Low speed saw blade is a cutting equipment. Low speed saw blade is specially designed for materials researchers and is an ideal sample preparation equipment for laboratories in scientific research institutes, colleges and universities, and industrial and mining enterprises.

2. Low speed saw blade is suitable for precision cutting of various crystals, medical materials and other material analysis samples, composite materials and organic polymer materials.

3. The rotation speed of the spindle of the low speed saw blade is infinitely adjustable. During the cutting process, the size of the cut sample is adjusted by relying on a digital micrometer, and the size control is precise.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Low Speed Saw Blade:

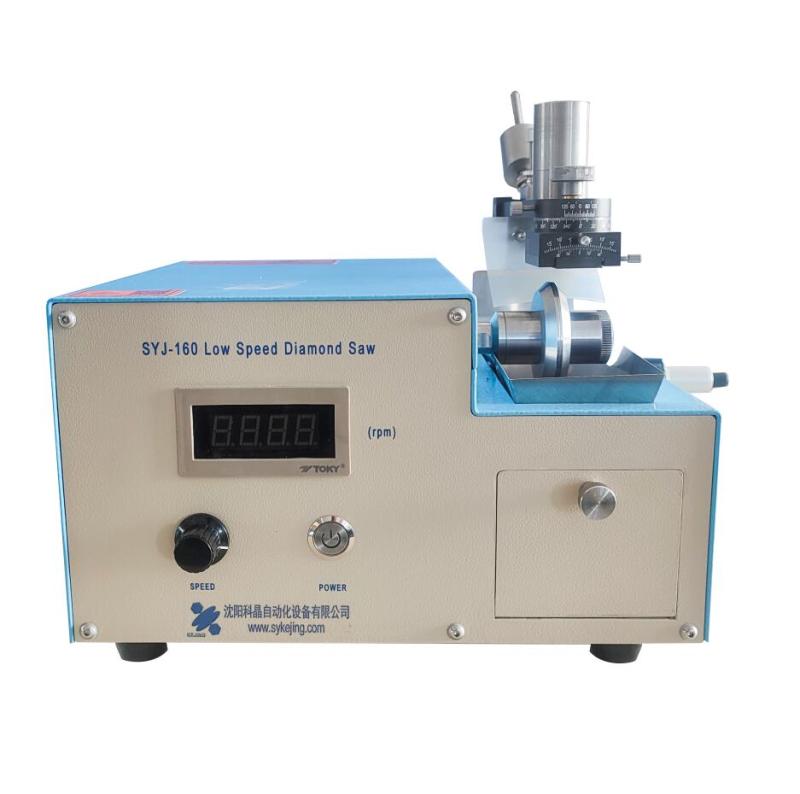

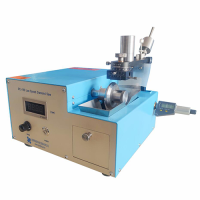

SYJ-160 Precision Low Speed Saw is a CE-certified precision cutting device designed for material researchers. It is an ideal sample preparation tool for research institutes, colleges and universities, and industrial and mining enterprise laboratories. Precision Low Speed Saw is widely used around the world.

Slow Speed Diamond Saw is suitable for precision cutting of various materials, including crystals (such as sapphire, garnet, etc.), ceramics, cement, glass, rock samples, mineral samples, metals, plastics, PCB boards, medical materials, dental materials, refractory materials, building materials, composite materials and organic polymer materials. Slow Speed Diamond Saw is particularly suitable for cutting and slicing materials, and supports cutting at a certain angle. The spindle speed of Precision Low Speed Saw is steplessly adjustable. The sample size is accurately adjusted through the digital micrometer during the cutting process to ensure high-precision size control.

SYJ-160 Digital Low Speed Diamond Saw is equipped with a cutting limit protection device to prevent the fixture from being scratched by the saw blade. According to the cutting requirements of different materials, users can replace different types of cutting saw blades (such as sintered diamond saw blades, electroplated diamond saw blades, corundum saw blades, silicon carbide saw blades, cubic boron nitride saw blades, etc.).

In addition, a cooling water box is provided under the saw blade of the Slow Speed Diamond Saw. With the help of the rotation of the saw blade, the coolant is brought to the sample, effectively taking away the heat generated during the cutting process, and preventing the sample from overheating and causing changes in the structure.

SYJ-160 Low Speed Saw Blade is compact and easy to operate, and is an indispensable cutting tool in the field of material research and sample analysis.

Main Features of Diamond Precision Cutting Machine:

1. Diamond precision cutting machine has large torque, low noise, smooth operation and compact structure.

2. The spindle of the diamond precision cutting machine operates with high precision, and the horizontal feed position of the processed sample can be fine-tuned.

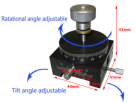

3. The digital low speed diamond saw is equipped with a 2D fixture so that the processed samples can be positioned and cut at the best angle.

4. Digital low speed diamond saw blades can be equipped with blades suitable for a variety of materials (such as sintered diamond blades, electroplated diamond blades, corundum blades, silicon carbide blades, cubic boron nitride blades) to meet the cutting requirements of different materials.

5. There is a coolant box under the precision low speed saw blade. The coolant is brought from the coolant box to the sample as the blade rotates, taking away the heat generated during the cutting process in time to prevent the sample from heating up and its texture change.

6. Precision low speed saw in addition, the saw machine is equipped with a limit device to enable unattended cutting.

7. Slow speed diamond saw compared with SYJ-150, the standard micrometer has a digital display and can use a blade with an outer diameter of 150mm to cut larger samples.

Technical Parameters of Diamond Precision Cutting Machine:

| Product Name | SYJ-160 Slow Speed Diamond Saw | |

| Product Model | SYJ-160 | |

| Installation Condition | 1. Temperature and humidity requirements: Relative humidity 10~85%RH (no condensation at 25℃), temperature range: 0~45℃. 2. Environmental requirements: There is no strong vibration source and corrosive gas around the Slow Speed Diamond Saw. 3. Power requirements: The Slow Speed Diamond Saw needs to use a national standard three-pole socket, AC100~240V, 50/60Hz, 10A, and ensure good grounding. | |

| Major Parameters | 1. Power supply voltage:DC24V 6.67A (standard "power adapter") 2. Drive motor power:90W 3. Spindle speed (effective value):minimum starting speed ~ maximum speed: 25~600rpm | |

| 4. Differential head: digital display |

Digital Micrometer (Standard) | |

5. Maximum feed stroke of slide:50mm 6. Slide fine adjustment stroke: 25 (accuracy 0.01) mm,digital display 7. Saw blade of size:Φ150×Φ12.7mm 8. Maximum cutting depth:50mm |  | |

9. Two-dimensional fixture ·Horizontal angle:360° ·Tilt angle:±15° |

Adjustable Sample Fixture | |

| 10. Loading block size:25mm×50mm | ||

| 11. Vise opening:25mm |

Mini Vise | |

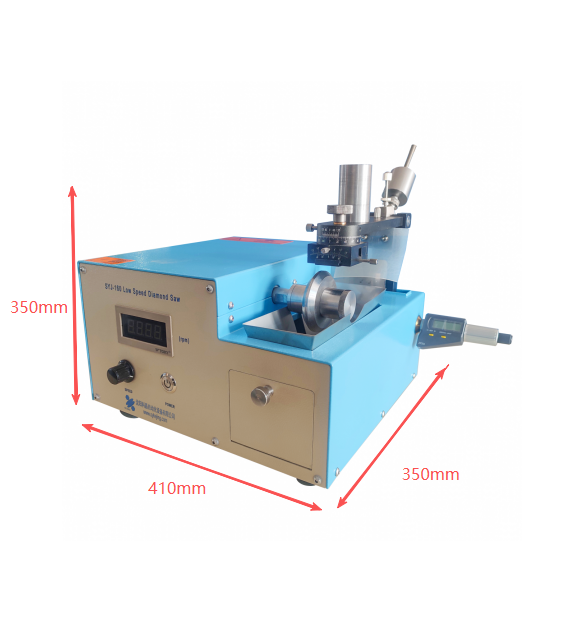

12.Specifications of Diamond Precision Cutting Machine: ·Dimension:410×350×350mm ·Weight: :15kg |  | |

Standard Accessories of Diamond Precision Cutting Machine:

No. | Name | Qty | Picture |

1 | Adjustable 2D Fixture | 1 set |  |

2 | Vise | 1 pcs |  |

3 | O-Ring of Driving Motor | 2 pcs |  |

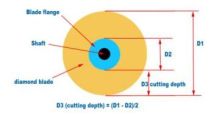

4 | Blade Clamp (Ø62mm、Ø48mm、Ø35mm) | total 3 sets |  |

5 | Aluminum Plate (25mm×50mm×6mm) | 2 pcs |

|

6 | Resin Bonded Ceramics (for Samples Holding) (50mm×50mm×10mm) | 2 pcs |  |

7 | Edge Sintered Diamond Blade (Ø150mm×Ø12.7mm×0.6mm) | 1 pcs |  |

8 | Silicon Carbide Blade (Ø150mm×Ø12.7mm×0.6mm) | 5 pcs |  |

9 | Corundum Blade (Ø150mm×Ø12.7mm×0.6mm) | 5 pcs |  |

10 | Wax Bar | 4 pcs |  |

11 | Goggles | 1 pair |  |

Optional Accessories of Low Speed Saw Blade:

No. | Name | Functional type | Picture |

1 | Full Sintered Diamond Blade (Ø150mm×Ø12.7mm×0.6mm) | (optional) |  |

2 | Silicon Carbide Blade (Ø150mm×Ø12.7mm×0.6mm) | (optional) |  |

3 | Corundum Blade (Ø150mm×Ø12.7mm×0.6mm) | (optional) |  |

4 | Edge Sintered Diamond Saw Blades (Ø150mm×Ø12.7mm×0.6mm) | (optional) |  |

Digital Low Speed Diamond Saw Notes and Warnings:

1. During the cutting process of low speed saw blade, you need to use cutting fluid containing cooling powder, or anti-corrosion fluid such as anti-rust agent and emulsion. Low speed saw blade avoid direct water cooling to prevent the saw from rusting.

2. When the digital low speed diamond saw stops sawing, the precision low speed saw speed should be reduced to zero (stop), and then the power switch can be turned off before the sample can be taken out.

3. When starting the low speed saw blade, make sure the sample is fixed and clamped firmly. Before turning on the switch, turn the speed control knob counterclockwise to zero, and then increase the speed.

4. After each use of the digital low speed diamond saw, the clamps and blades should be cleaned, protected, dried, oiled, and rust-proofed before being stored.

5. Digital low speed diamond saw In order to prevent oxidation or contamination of the cutting surface of the sample, the diamond precision cutting machine can be operated in a nitrogen-filled glove box, but the precision low speed saw cannot be operated in an argon-filled condition (that is, the glove box has nitrogen, but no argon).

If you are interested in our Diamond Precision Cutting Machine, please feel free to consult us.

Warranty of Digital Low Speed Diamond Saw:

Digital Low Speed Diamond Saw has one year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Quality Promise of Precision Low Speed Saw:

Our company guarantees the Precision Low Speed Saw is brand new, unused, and meets contract specifications. Precision Low Speed Saw will perform well with proper installation, use, and maintenance. We cover design or material defects for twelve months after final acceptance.