Abrasive Cutting Machine For Cutting Metallographic Sample

1. Metalographic sample cutting machine is a manual high-speed cutting equipment.

2. Metallographic sample cutting machine is mainly used for cutting various metallographic samples with high-speed rotating grinding discs. Abrasive Cutting Machine is widely used in colleges and universities, scientific research institutes, steel, automobiles, machine tools and other fields.

3. The Metallographic sample cutting machine is small in size, saving laboratory space, and Abrasive Cutting Machine equipped with a protective cover for safe operation.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

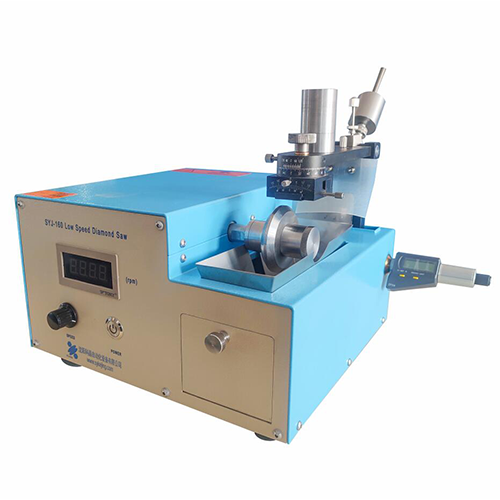

Introduction of Metallographic cutting machine:

SYJ-50 Metallographic cutting machine is a fast manual cutting device with CE certification. It uses high-speed rotating grinding wheel for sample cutting. It is suitable for various metal materials. Metallographic cutting machine is widely used in colleges and universities, scientific research institutes, steel, automobiles, machine tools and other fields.

In addition, SYJ-50 Metallographic cutting machine is also suitable for fast cutting of various materials such as resin and ceramics. It is an ideal choice for material cutting or slicing. Abrasive Cutting Machine can replace the corresponding saw blade according to different specimens, and the operation is simple and easy to learn. When using, you only need to fix the sample and manually feed the saw blade downward until the cutting is completed. The cutting speed is manually controlled by the user, which is convenient and efficient to operate.

SYJ-50 Abrasive Cutting Machine is small in size, saving laboratory space. It uses water cooling to cool the sample during cutting and is equipped with a protective cover to ensure safe operation.

Metallographic Sample Cutting Machine Main Features:

1. The metallography specimen cutting machine is equipped with dual quick clamps, which make sample fixing quick and convenient. Metallographic cutting machine is suitable for fixing crankshafts, valves and other complex-shaped objects.

2. The metallography specimen cutting machine uses a side-pressure operating lever, which is convenient and quick to operate.

3. The metallography specimen cutting machine has safety lighting and a transparent resin observation window, which facilitates observation during the cutting process and is safe and reliable.

4. The metallography specimen cutting machine table is made of stainless steel to prevent rust and corrosion.

5. Metallographic Cut-Off Machines have built-in coolant pipelines that can directly and quickly supply coolant to the sample to avoid overheating and changes in the metallographic structure during the cutting process.

Technical Parameters of Metallographic Cut-Off Machines:

Product name | SYJ-50 Metallographic Cut-Off Machines (for cutting metallographic samples) | |

Product model | SYJ-50 | |

Installation conditions of metallography specimen cutting machine | 1. Temperature and humidity:10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There are no strong earthquake sources and corrosive gases around the equipment. 3. Power supply:three-phase four-wire: AC380V 50Hz C16A air switch must have a good ground wire. 4. The cooling water equipment is equipped with an upper water outlet and a lower water outlet, and you need to connect the tap water and drainage (circulating water tank) by yourself. 5. Air source:no such requirement. 6. Workbench:Recommended size: 800mm×650mm×700mm, load-bearing over 100kg. 7. Ventilation device:good ventilation environment, no special ventilation device requirements are required. | |

Metallographic cutting machine major parameters (specification) | 1. Power supply port:three-phase: AC 380V 50Hz 2. Total power of Abrasive Cutting Machine:1.2kW 3. Spindle speed:2800rpm 4. Spindle drive motor:three-phase AC asynchronous motor:AC 380V 1.1kW 5. Cutting workpiece size:Ø50mm×50mm 6. Maximum opening of clamp (caliper):≥50mm 7. Saw blade of Metallographic sample cutting machinesize: outer diameter: Ø250mm, inner diameter: Ø25.4mm or Ø32mm, thickness: 2mm | |

8. Metallographic Cut-Off Machines dimension and weight: ·Dimension:750mm×620mm×650mm ·Weight:≈85kg |

| |

Standard Accessory of Metallographic Cut-Off Machines:

No. | Name | Qty | Picture |

1 | Blade clamp (Ø20mm×Ø80mm) | 1 set | |

2 | Silicon carbide blade (Ø250mm×Ø32mm×2mm) | 2 pcs |

|

3 | Corundum blade (Ø250mm×Ø32mm×2mm) | 2 pcs |

|

Metallographic Cut-Off Machines Optional Accessory:

No. | Name | Fuctional type | Picture |

1 | Edge Sintered Diamond Blade (Ø250mm×Ø32mm×1.2mm) | (Optional) |

|

2 | YJXZ-12 Liquid (for circulating coolant) | (Optional) |

|

3 | YXZ-25Y Automatic Filter Circulating Water Tank | (Optional) |

|

Metallographic sample cutting machine Remarks and warnings:

It is recommended that customers use anti-corrosion coolant during the cutting process of Abrasive Cutting Machine to avoid rusting of the screw.

Metallographic cutting machine be sure to clean the machine after each use.

Warranty of Abrasive Cutting Machine:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Enterprise strength:

Our company often participates in exhibitions around the world, and this conference aims to provide a scientific and technological exchange platform for the world's advanced materials industry. Many internationally renowned experts and scholars in the field of advanced materials gathered together to exchange the latest technological achievements and scientific research experience with participants from all over the world, and conduct research and discussion on hot issues and future development directions in the field of advanced materials. materials in the world.