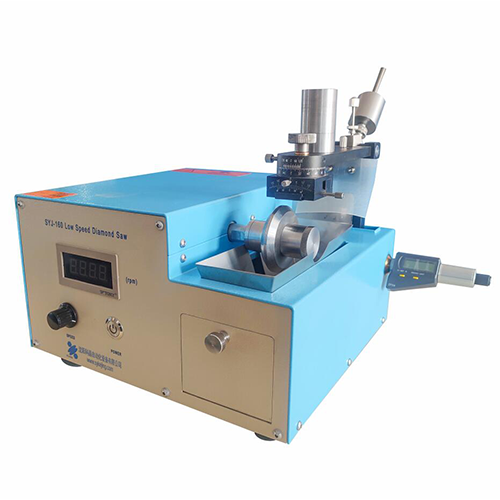

Automatic Section Saw With 8" Cutting Blades

1. Metallurgical sectioning saw (or profile saw) is a precision cutting equipment.

2. Metallurgical sectioning saw is widely used in factories, colleges and universities, and scientific research institutes.

3. Metallurgical sectioning saw is suitable for precision cutting of metals, crystalline ceramics, glass, rock samples, mineral samples, concrete, organic materials, polymer materials, composite materials, etc., such as fasteners, spark plugs, valves, and medical artificial joints.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Automatic section saw:

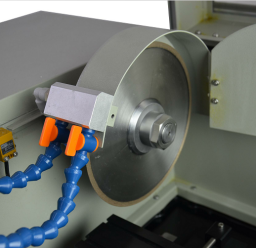

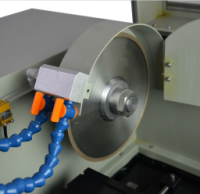

SYJ-200 High Speed Saw is a high-precision cutting equipment with CE certification.

High Speed Saw is widely used in factories, colleges and universities, and research institutes. It is designed for cutting metals, crystals, ceramics, glass, rock samples, mineral samples, concrete, organic materials, polymer materials and composite materials. Automatic section saw is suitable for cutting fasteners, spark plugs, valves, artificial joints and other samples.

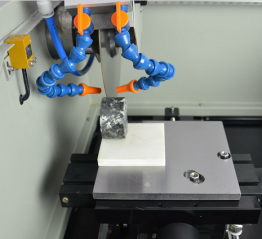

SYJ-200 Precision Section Saw is equipped with a high-precision control system, and the spindle speed can be adjusted steplessly. It can be adjusted to the maximum speed during cutting to ensure efficient and accurate cutting. Industrial Precision Section Saw is equipped with limit protection. When the limit is exceeded, the machine automatically stops to ensure safe operation. The metallurgical sectioning saw is equipped with a waterproof cover to prevent water splashing during cutting, avoid damage to the saw blade and accidental injury.

SYJ-200 High Speed Saw is compact, space-saving, easy to operate and safe, and is an ideal choice for material analysis sample preparation. In addition, the clamp can be customized according to cutting needs to enhance the cutting flexibility and operation convenience of the Automatic section saw.

Main features of Industrial Precision Section Saw:

1. Industrial Precision Section Saw has stepless speed regulation, large torque and smooth operation.

2. Industrial Precision Section Saw large-size color digital display touch screen, parameters can be adjusted accurately.

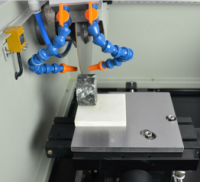

3. Industrial Precision Section Saw X-axis and Y-axis are driven by stepper motors.

4.metallurgical sectioning saw is equipped with a coolant circulation system.

Technical Parameters of Automatic Section Saw:

Product Name | SYJ-200 High Speed Saw (for Precision Cutting) | |

Product Model | SYJ-200 | |

Conditions for Installation of Automatic section saw

| 1. Temperature and humidity:10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. High Speed Saw there are no strong earthquake sources and corrosive gases around the equipment. 3. Power supply:AC220V 50Hz national standard three-pole 10A socket, which must have a good ground wire 4. Cooling water:The equipment is equipped with an upper water outlet and a lower water outlet. You need to connect tap water and drainage (circulating water tank) by yourself. 5. Air source:No need for standard equipment 6. Workbench:Recommended size is 800mm×600mm×700mm, with a load capacity of more than 100kg 7. Ventilation device:good ventilation environment, no special ventilation device requirements are required | |

Major Parameters (Specification) of High Speed Saw | 1. Power supply port: AC220V 50Hz 10A 2. Total power:650W 3. Spindle speed:effective value:300-3500rpm stepless speed regulation 4. Spindle drive motor:DC220V 600W 4000rpm 5. X-axis skateboard stroke: 80mm 6. Y-axis skateboard stroke:105mm 7. X/Y axis drive motor:high-precision stepper motor 8. Stepper motor positioning accuracy:0.01mm 9. Precision Section Saw opening of clamp (vise):55mm 10. Automatic Section Saw Saw blade size: ·outer diameter: φ200mm ·inner diameter: φ25.4mm or φ32mm 11. High Speed Saw Host control mode: touch screen + PLC programming control | |

12. Precision Section Saw Dimension and weight · dimension: 740mm×590mm×490mm · weight:≈72kg |

| |

Automatic Section Saw Standard Accessories:

No. | Name | Qty | Picture |

1 | Blade Clamp (φ32mm, φ25.4mm) | total 2 sets |  |

2 | Resin Ceramic Block | 2 pcs |  |

3 | Edge Sintered Diamond Blade φ200×φ25.4×1.0mm | 1 pcs |  |

4 | Silicon Carbide Blade φ200×φ32×1.2mm | 2 pcs |

|

5 | Corundum Blade φ200×φ32×1.2mm | 2 pcs |

|

6 | YJXZ-12 Liquid Circulating Pump | 1 set |

|

7 | Wax Bar | 10 pcs |

|

Automatic Section Saw Optional Accessories:

No. | Name | Fuctional type | Picture |

1 | JXZ-25Y Automatic Filter Circulating Water Tank | (optional) |  |

2 | SYJ-200 Special Tooling Series | (optional) |  |

Metallurgical Sectioning saw Remarks and Warnings:

It is recommended that customers use anti-corrosion coolant during cutting with High Speed Saw to prevent the screw from rusting.

After each use of the High Speed Saw, please clean the machine, especially the screw, and add lubricant after each use. Ensure that the X and Y axes of the High Speed Saw can move freely without getting stuck or rusting.

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Quality Commitment:

Our company guarantees that the equipment provided is brand new, unused, and fully meets the quality, specification and performance requirements specified in the contract, and that our equipment should have satisfactory performance under correct installation, correct use and maintenance conditions and during its service life.