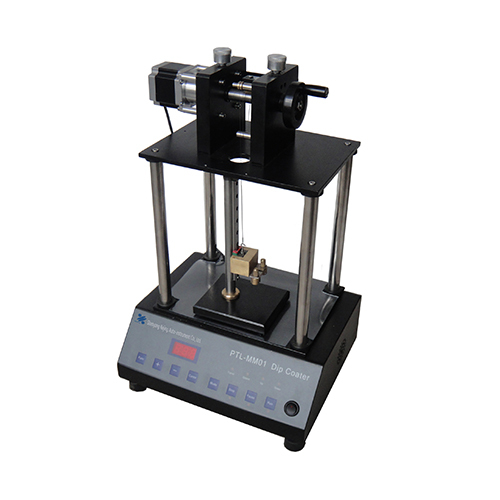

6 Position Programmable Dip Coater With Speed 1-400 mm/min

PTL-6P Six-Position Dip Coater can pull one sample at a time, and can make the sample rotate counterclockwise through program control. The sample is pulled out for drying after being dipped in the charging beakers for a certain period of time. The dipping time and drying time can be set through programming. The six charging beakers of PTL-6P six-station dip coater can be loaded with the same coating material or different coating materials separately.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Description

The PTL-6P Six-Station Pull-Up Coating Machine can process one sample at a time. The sample rotates counterclockwise under program control and is immersed in the liquid-filled beaker for a set time before being pulled out for drying. Both the immersion time and drying time can be programmed. The six beakers of the PTL-6P can hold the same film material or different materials simultaneously. During the coating process, the beakers are not heated, making this machine suitable for liquid film materials or flowable paste-like films. With its compact design, space-saving footprint, easy operation for beginners, and simple cleaning, the PTL-6P is widely used in laboratories of universities, research institutes, and enterprises.

Main Features

1. There are 6 work stations/positions, and the samples can be rotated counterclockwise.

2. Program-controlled pulling speed, dipping time and drying time, etc.

3. A high-precision stepper motor is adopted.

4. CE certified.

Technical Parameters

Product Name | PTL-6P Six-Position Dip Coater | |

Product Model | PTL-6P | |

Installation Conditions | This equipment is required to be used at an altitude of 1000m or less, a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 1. Water: N/A 2. Electricity: AC220V 50Hz, must have good grounding 3. gas: N/A 4. Workbench: size 500mm×800mm×700mm, bearing more than 50kg 5. Ventilation device: no need | |

Main Parameters (Specification) | 1. Power supply: AC220V 50Hz 2. Stirring speed: low speed/high speed (whether each station/position needs stirring or not, it can be set separately. ) 3. pulling speed: automatic ascending and descending speed: 1-400 mm/min, manual ascending and descending speed: 1-150 mm/min 4. pulling times: 1-45 times 5. Dipping and drying time setting: 1-999s 6. Travel distance setting: 1-80mm (adjustable) 7. beaker: 150ml 8. Effective dipping length: 60mm 9. Sample size: 75mm×25mm×2mm | |

Product Dimension and Weight | 10. Product Specifications · Dimension: 260mm×340mm×420mm · weight: 15kg |

|

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Sample Clamp (single piece) | 1 pcs | - |

| 2 | Loading Beakers | 6 pcs | - |

Optional Accessories

| No. | Name | Function Category | Image |

| 1 | Sample Clamps (double piece) | Optional | - |

| 2 | other Clamps | Optional | - |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics