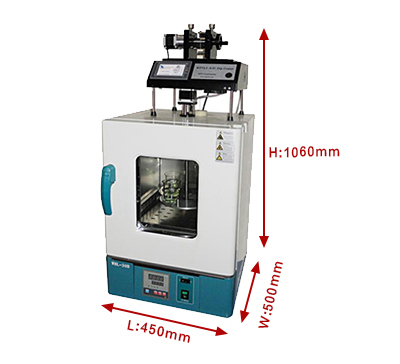

5-Position Dip Coater With Speed And Heating Chamber

PTL-OV5P Automatic 5-Position Thermostatic Dip Coater is used for multi-layer (up to 5 layers) dipping and coating of the same sample in different liquid coating materials. The machine is equipped with a pulling wire to fix up to two identical samples for dipping and coating at the same time. After one coating, manually turn the charging beaker to make the sample enter the next coating process. This machine is equipped with a thermostatic oven.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

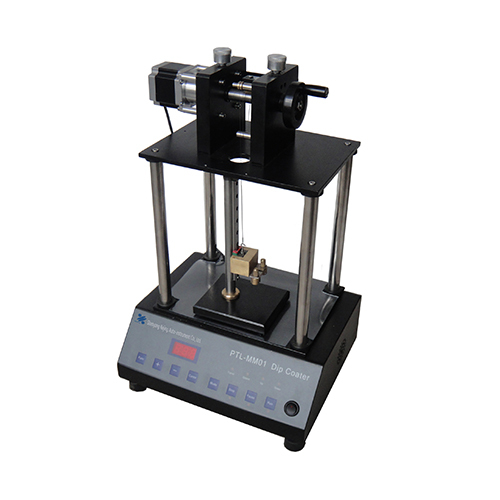

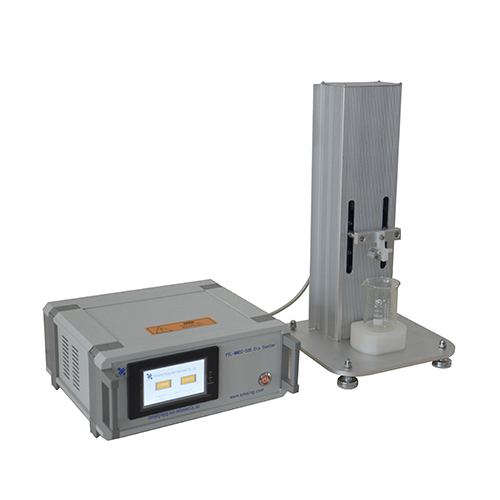

The PTL-OV5P Fully Automatic 5-Position Constant Temperature Dip Coater is a millimeter-scale, multi-position precision dip-coating system with temperature control, designed specifically for research institutions. It is mainly used for preparing multilayer liquid-phase thin film materials on the same sample across different liquid phases. With its compact structure, simple operation, and convenient portability, it has been widely applied in universities, research institutes, and enterprise laboratories.

Main Features

1. Multi-Position Switching: Equipped with 5 liquid material positions, supporting up to 2 samples for dip-coating in as many as 5 different liquids (multilayer). The liquid positions can be automatically switched and controlled.

2.Working Environment: Features a constant-temperature heating chamber, allowing operation at room temperature or under controlled heating conditions to meet temperature-sensitive process requirements.

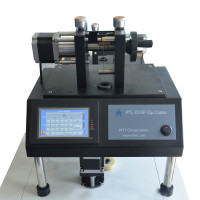

3. User-Friendly Operation: A 4.3-inch color touchscreen with a clean and intuitive interface makes operation simple.

4.High-Precision Control: PLC programming combined with suspension wire transmission technology effectively reduces vibration interference.

5.Space Optimization: Compact design with high cost-performance ratio, saving valuable laboratory space.

Technical Parameters

Product Name | PTL-OV5P Automatic 5-Position Thermostatic Dip Coater |

Product Model | PTL-OV5P |

Installation Conditions | 1. Power Supply: AC220V 50/60Hz. 2. Operating Environment: Temperature 25℃ ±15℃, humidity 55%Rh ±10%Rh; free of dust, vibration, flammable, explosive, and corrosive gases. |

Main Parameters (Specification) | 1. Lifting Unit Operating Voltage: DC24V 3.75A (standard: AC100~240V power adapter) 2. Lifting Unit Power: 50W 3. Type: Programmable – Constant Temperature Model (with constant temperature chamber) 4. Drive Motor: High-precision stepper motor 5. Speed Range: 1–200 mm/min 6. Dwell Time: 1–999 s 7. Drying Time: 1–999 s 8. Lifting Stroke: 1–75 mm 9. Lifting Cycles: 1–20 times 10. Lifting Stations: 1 station (capable of holding 1–2 substrates) 11. Effective Immersion Depth: ≤60 mm 12. Substrate Size Range: (L: 75 mm) × (W: 25 mm) × (T: 2.5 mm) 13. Maximum Lifting Load: ≤100 g 14. Cup Stations (Immersion Positions): 5 (can hold 5 different solutions simultaneously) 15. Cup Specification (Beaker): Φ60, 150 ml 16. Cup Tray Load Capacity: Total ≤3000 g (≤500 g per station) 17. Display & Control: 4.3-inch color touchscreen |

18. Product Specifications · Dimension: 455mm×500mm×1060mm · weight: 45kg | |

19. Temperature-Controlled Chamber Specifications: · Temperature Range: RT (room temperature) to +100℃ · Temperature Control/Setting: Dual-row digital PID with four touch buttons · Heating Timer: 0–9999 minutes or hours · Rated Heating Power: 0.8 kW · Rated Current: 3.6 A · Operating Voltage: AC220V 50/60Hz · Internal Dimensions (Volume): 310 mm × 310 mm × 310 mm (30 L) · External Dimensions: 455 mm (L) × 500 mm (W) × 723 mm (H) |

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Coating Fixture | 1 set | - |

| 2 | Beaker (150ml) | 5 pcs | - |

| 3 | Pulling Wire | 3 pcs | - |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics