1700℃ Small High Temperature Box Furnace (1.7L)

1. Our industrial muffle furnace reaches a maximum temperature of 1700°C. Made in China, our models are standardized, and some models can be customized with components. Please contact our sales staff for details regarding specific implementation differences.

2. Our industrial muffle furnace utilizes high-purity alumina fiber insulation, making it suitable for applications such as ceramics and metals, offering a long lifespan and easy maintenance.

3. Our industrial muffle furnace utilizes an integrated control system, suitable for both experimental and small-batch production.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the Industrial Muffle Furnace:

The KSL-1700X-S is a high-temperature small box furnace. It uses silicon-molybdenum rods as heating elements. The small box furnace features a double-shell structure, PID programmable temperature control, and a B-type thermocouple. The furnace chamber is constructed of high-purity alumina fiber. Its maximum temperature can reach 1700°C, with a continuous operating temperature of 1600°C and a temperature control accuracy of ±1°C. The small box furnace offers advantages such as uniform temperature distribution, low surface temperature, and energy efficiency. It is ideal for high-temperature sintering, metal annealing, and quality inspection in universities, research institutes, and industrial and mining enterprises.

Main Features of the Small box furnace:

· The furnace chamber of Mini box furnace is constructed of high-purity alumina fiber, minimizing energy loss.

· The furnace chamber of Mini box furnace is coated with a high-temperature alumina coating imported from the United States, improving heating efficiency and service life.

· The mini box furnace is equipped with overheating and burnout protection, and features a door-opening power-off function. The Mini Box Furnace features built-in air intake and exhaust ports to remove undesirable contaminants and moisture, extending the life of the heating element and furnace.

· The Mini Box Furnace utilizes 1700-grade silicon-molybdenum rods, achieving a maximum temperature of 1700°C.

Technical Specifications of the Mini Box Furnace

| Product Model | 1700°C Small High-Temperature Industrial muffle furnace (1.7L) KSL-1700X-S |

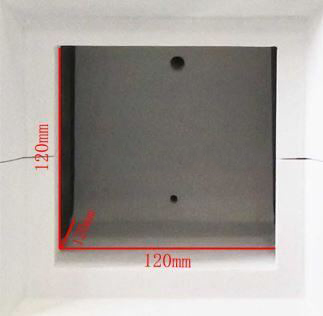

| Technical Parameters of Mini box furnace | Power Supply of Industrial muffle furnace: AC 220V/50Hz Power of Mini box furnace: 2.5kW Heating Zone Dimensions of Mini box furnace: 120*120*120mm (L*W*H)

Maximum Operating Temperature of Industrial muffle furnace: 1700°C (≤30min). Long-Term Operating Temperature of Small box furnace: 1600°C. Recommended Heating Rate: ≤10°C/min (≤1400°C) ≤5°C/min (1400-1600°C). ≤2°C/min (>1600°C). Heating Elements: Silicon-Molybdenum Rods (4). Thermocouple: Type B. |

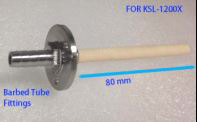

| Atmosphere of Small box furnace | Air inlet and outlet ports are located at the rear and top of the furnace, allowing inert gas to flow into the chamber. The air inlet is a 6mm diameter pagoda nozzle, and the air outlet is a 30mm diameter circular outlet.

|

| Temperature Control System of Small box furnace | · Includes a YD858P temperature controller. · PID automatic temperature control system. · Intelligent 50-segment programmable control. · Temperature control accuracy: ±1°C. · Default DB9 PC communication port. · MET certified. · Optional PC temperature control software (for the YD858P series controller) is available for controlling heating curves and exporting data.

|

| Specifications of Small box furnace | Dimensions: 380mm(L)×410mm(W)× 620mm(H) Approximate weight: 60kg |

| Compliance of Small box furnace | CE Certified, UL or CSA certification is available at extra cost. |

The relationship between power consumption and power consumption of a high-temperature mini box furnace:

When using mini box furnaces of the same size but different power ratings to heat to 1,000°C, the heat required to heat a high-power mini box furnace to 1,000°C is the same as that required to heat a low-power Small box furnace to the same temperature. The only difference is that the high-power small box furnace performs more work per unit time and heats faster. This is because the small box furnace can generate more heat in a shorter period of time, reaching the required temperature faster. On the other hand, the low-power muffle furnace performs less work per unit time and generates less heat in the same period of time, so it naturally takes longer to reach the required temperature.

Methods for Reducing Mini box furnace Power Consumption:

The power consumption of a muffle furnace is affected by factors such as the size of the furnace chamber, the insulation material and thickness, and the material and size of the heating material. Therefore, to reduce the power consumption of a muffle furnace, you can consider the following aspects:

1. Choose a reasonable furnace chamber size.

2. Select appropriate insulation materials.

3. Ensure the material and size of the heating material are appropriate.

The difference between a tube furnace and a Industrial muffle furnace:

1. Different production volume: Since the diameter of a tube furnace is fixed, its production volume is relatively small; while the size of the muffle furnace can be adjusted, the test or production volume is larger. 2. Different calcination atmosphere: When using a tube furnace for calcination, the workpiece cannot be fully integrated with the air, which easily leads to incomplete calcination; while in a muffle furnace, the workpiece can be fully integrated with the air during the calcination process, so that it can be fully calcined.

What are the factors that affect the temperature error of a Small box furnace?

1. Error caused by the thermocouple:

(1) Thermocouple unevenness.

(2) Thermocouple instability.

2. Display error:

(1) The influence of cold end temperature

(2) The influence of nonlinearity.

(3) The influence of signal processing.

Demonstrating Our Strength:

Our company has many years of experience in the research and development and manufacturing of high-temperature Industrial muffle furnace. We have obtained international certifications and possess comprehensive production, testing, and R&D capabilities. Our products are widely used by universities, research institutes, and industrial and mining enterprises both domestically and internationally, and have been granted numerous patents and technological achievements.

We have established a nationwide and global after-sales service network, guaranteeing a one-year free warranty (excluding wearing parts) from the date of delivery and lifetime technical support. Our responsive after-sales team ensures the long-term stable operation of our customers' equipment.

In terms of long-term corporate strength and after-sales service, the company has always maintained a customer-centric focus, continuously investing resources to improve product quality and service levels. Since its establishment, the company has been deeply engaged in the industrial muffle furnace industry for many years, accumulating rich technical experience and market reputation. The company has a comprehensive R&D system and production line, enabling it to continuously launch new industrial muffle furnaces that align with industry trends and provide customized solutions based on customer needs. The core technical team maintains exchanges and collaborations with leading domestic and international research institutions to ensure continuous technological innovation and upgrades.

In terms of after-sales service, the company has established a professional technical support and service team for small box furnaces, providing full lifecycle support. From small box furnace selection, installation and commissioning, operator training, to routine maintenance, troubleshooting, and spare parts supply, the company has dedicated personnel to ensure that any problems encountered during the use of small box furnaces are promptly and effectively resolved. For key customers and large projects, the company also arranges regular inspections and remote diagnostic services to proactively prevent and resolve potential problems and minimize equipment downtime.

Furthermore, the company promises lifelong technical support and continuous upgrades for all Mini Box Furnaces. Whether it's software system updates or hardware feature expansions and upgrades, we flexibly respond to customer needs. Our well-managed spare parts inventory ensures off-the-shelf availability of common Mini Box Furnace parts and rapid customization of specialized accessories, ensuring uninterrupted production and experimental use of Mini Box Furnaces. The company also prioritizes customer feedback, conducting regular satisfaction surveys and return visits, and optimizing Mini Box Furnace and service processes based on user feedback, truly achieving our long-term goal of shared growth and win-win cooperation with our customers.