1200℃ Tabletop Box Oven (with Quartz Observation Window, 7.2L) KSL-1200X

1. Our vacuum box furnace uses resistance wire heating, which has the advantages of simple structure, low cost, and good stability.

2. Our vacuum box furnace has a PID automatic temperature control system with high temperature control accuracy.

3. Our vacuum box furnace is a specialized piece of equipment developed specifically for laboratories in universities, research institutes, and industrial and mining enterprises.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of High Temperature Box Furnace:

The KSL-1200X high temperature box furnace uses resistance wire as the heating element, employs a double-layer shell structure and 50-segment programmable temperature control, and K-type thermocouples. The furnace chamber is made of high-purity alumina fiber material. The maximum temperature can reach 1200 degrees Celsius, with a continuous operating temperature of 1100 degrees Celsius and a temperature control accuracy of ±1 degree Celsius. The high temperature box furnace features a uniform temperature field, low surface temperature, rapid heating and cooling, and energy efficiency. It is an ideal product for high-temperature sintering, metal annealing, and quality inspection in universities, research institutes, and industrial and mining enterprises.

Key features of the high temperature box furnace:

▪ The furnace door of small box furnace features a φ15mm quartz glass observation window for customers to observe sample changes during heating.

▪ The furnace chamber of small box furnace is made of high-purity alumina fiber, reducing energy loss.

▪ The furnace chamber of small box furnace surface is coated with an imported high-temperature alumina coating from the USA, improving heating efficiency and extending service life.

▪ The furnace chamber of small box furnace has built-in air inlets and outlets to remove contaminants and moisture, extending the lifespan of the heating elements and furnace chamber.

▪ The small box furnace features overheat and thermocouple breakage protection, and a door-open power-off function.

▪ The furnace chamber of small box furnace is heated on three sides, resulting in rapid heating and a uniform temperature field.

Technical parameters of vacuum box furnace:

| Product Model | 1200℃ Tabletop high temperature box furnace (with Quartz Observation Window, 7.2L) KSL-1200X |

| Open-type resistance wire furnace lining | Features of high temperature box furnace: Low pollution, corrosion resistant Power Supply of vacuum box furnace: AC220V 50HZ/60HZ Power of small box furnace: 3.5KW Heating Zone Dimensions of small box furnace: 200*300*120mm (L*W*H)

Maximum Operating Temperature: 1200℃ (≤30min) Operating Temperature: 1100℃ Recommended Heating Rate: ≤10℃/min (Recommended heating rate for optimal equipment lifespan) Heating Element: Resistance Wire (Molybdenum-doped Iron-Chromium-Aluminum Alloy) Thermocouple: Type K |

| Corrosion-resistant coating embedded resistance wire | Features: Low pollution, corrosion resistant · Power supply: AC220V 50HZ/60HZ · Power: 3.5KW · Heating zone dimensions: 200*300*120mm (L*W*H) · MAX operating temperature: 1100℃ (≤30min) · Working temperature: 1000℃ · Recommended heating rate: ≤10℃/min (Recommended heating rate to benefit equipment lifespan) · Heating element: Resistance wire (molybdenum-doped iron-chromium-aluminum alloy) · Thermocouple: Type K |

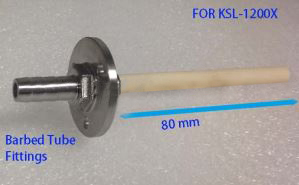

| Observation window | · Quartz glass observation window on the furnace door, φ15mm in size · An air inlet device can be installed on this observation window as an air inlet (using a φ5mm stainless steel pagoda nozzle connector on one end and a corundum tube on the other, installed on the furnace door as an air inlet to allow gas to enter). · In addition, this hole can be used as a feedthrough for calibrating temperature or measuring the electrical properties of samples.

|

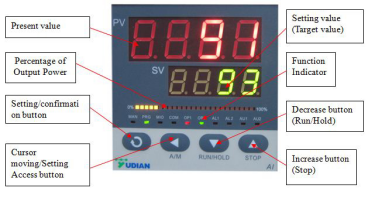

| Temperature control system of small box furnace | Includes a YD858P temperature controller. · PID automatic temperature control system. · Intelligent 50-segment programmable control. · Temperature control accuracy: ±1℃ · Default DB9 PC communication port. · MET certified. · Optional computer temperature control software (for YD858P series controllers) for controlling the temperature rise curve and exporting data.

|

| Product Specifications | · Dimensions of small box furnace: (Without opening) 470mm (L) * 454mm (W) * 580mm (H) · Net weight: Approximately 45kg |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Warranty period for the vacuum box furnace:

The small box furnace has a 1-year warranty (excluding consumable parts such as pads and heating elements).

Precautions for vacuum box furnaces:

· Before use, please insert the gasket and door plug; otherwise, the furnace chamber and door may be damaged.

· If individual heating elements of the vacuum box furnace are damaged and need replacement, select replacement elements with appropriate resistance values based on the current resistance increase of other components. Do not arbitrarily replace new elements. If the damage to an element is too great and the required furnace temperature cannot be reached, it is recommended to replace all elements with new ones.

· To maintain the service life of the vacuum box furnace components, we recommend that the heating rate not exceed 10°C/min. The cooling rate should also not exceed 10°C/min.

· Sintering flammable, explosive, toxic, and corrosive substances inside the vacuum box furnace is prohibited. If the customer's process necessitates the use of flammable, explosive, toxic, and corrosive substances, the customer must take appropriate protective and explosion-proof measures. Our company is not responsible for any problems caused by the use of flammable, explosive, toxic, and corrosive substances during the operation of the vacuum box furnace.

Our Commitment:

With years of experience, we have complete confidence in our high temperature box furnaces. We have conducted tens of thousands of tests in our factory to minimize the error rate.

We hope to let customers worldwide know about Shenyang Kejing and experience our high-quality, precision equipment. Welcome your inquiries.

Email: krd@sykejing.com

Tel:(+86)18624331853(Wechat)(WhatsAPP)