1200℃ Top-loading Muffle Furnace(9L)VBF-1200X

1. Our high temperature laboratory furnace features a PID automatic temperature control system, offering high precision and improving the quality of research results.

2. Our high temperature laboratory furnace is compact and portable (9L), enhancing work efficiency.

3. Our high temperature laboratory furnace uses high-efficiency heat-resistant insulation materials in the furnace chamber, improving heating speed and service life.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the High Temperature Laboratory Furnace:

The VBF-1200X high temperature lab furnace uses resistance wire as the heating element, employs a double-layer shell structure and 50-segment programmable temperature control, K-type thermocouples, and a furnace chamber made of high-purity aluminum hydride fiber material. It can reach a maximum temperature of 1200 degrees Celsius, with a continuous operating temperature of 1100 degrees Celsius and a temperature control accuracy of ±1 degree Celsius. The high temperature lab furnace features a uniform temperature field, low surface temperature, rapid heating and cooling, and energy efficiency. It is an ideal product for universities, research institutes, and industrial enterprises for high-temperature sintering, metal annealing, and quality inspection.

Key features of the high temperature lab furnace:

1. The high temperature lab furnace features a top-opening door structure for convenient sample placement and retrieval.

2. The vertical muffle furnace lining is made of high-purity alumina fiber, minimizing energy loss.

3. The furnace lining surface is coated with an imported high-temperature alumina coating from the USA, improving heating efficiency and extending service life.

4. The vertical muffle furnace has overheat and thermocouple failure protection, and a door-open power-off function.

5. Refractory bricks are installed at the furnace bottom to prevent furnace lining wear.

Technical parameters of the vertical muffle furnace:

| Product Model | 1200℃ Small Pit Furnace (9L) VBF-1200X |

| Technical Parameters | · Power Supply of high temperature lab furnace: AC220V/50HZ · Power: 3.5KW · Heating Zone Dimensions: φ240*220mm · Maximum Operating Temperature: 1200℃ (≤30min) · Long-Term Operating Temperature: 1100℃ · Recommended Heating Rate: ≤10℃/min · Heating Element: Resistance Wire (Molybdenum-Doped Iron-Chromium-Aluminum Alloy) · Thermocouple: Type K · Temperature Control Accuracy: ±1℃ |

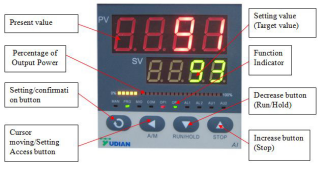

| Temperature Control System | · Includes one YD858P temperature controller. · PID automatic temperature control system. · Intelligent 50-segment programmable control. · Temperature control accuracy: ±1℃. · Default DB9 PC communication port. · MET certified. · Optional computer temperature control software (for YD858P series controllers) for controlling temperature rise curves and exporting data.

|

| Specifications of vertical muffle furnace | Dimensions: 620mm (L) 540mm (W) 880mm (H); Weight: Approx. 45Kg |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Warranty period for the vertical muffle furnace:

The vertical muffle furnace has a 1-year warranty (excluding consumable parts such as pads and heating elements).

About us:

1. Shenyang Kejing enjoys a strong reputation and rich practical experience in the industry. For many years, we have continuously served well-known domestic and international enterprises, research institutions, and universities, establishing long-term cooperative relationships with them. We have also won high recognition from our clients with our reliable products and services.

2. For key clients and large-scale projects, the company can provide remote diagnostic services, proactively identifying and resolving potential problems to minimize equipment downtime. (For detailed information, please contact customer service.)

3. Our core technical team maintains close communication and cooperation with leading research institutions worldwide. We possess a complete R&D system and production line, enabling us to customize exclusive production solutions according to specific client needs.