1700℃ High Temperature Box Furnace (8L)

1. Our muffle furnace with gas inlet achieves a maximum temperature of 1700°C, ensuring long-term stable operation and continuous heat retention.

2. Our muffle furnace with gas inlet boasts a high heating rate, accelerating the process.

3. This muffle furnace with gas inlet is suitable for ashing, annealing, sintering, pre-firing, and heat treatment applications.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the Muffle Furnace with Gas Inlet:

The KSL-1700X-A2 is a high-temperature small box furnace. Muffle furnace with gas inlet uses silicon-molybdenum rods as heating elements. The small box furnace features a double-shell structure, PID programmable temperature control, a B-type thermocouple, and a furnace chamber made of high-purity alumina fiber. Electric muffle furnace can reach a maximum temperature of 1700°C and a continuous operating temperature of 1600°C with a temperature control accuracy of ±1°C. The small box furnace offers advantages such as uniform temperature distribution, low surface temperature, and energy efficiency. It is ideal for high-temperature sintering, metal annealing, and quality inspection in universities, research institutes, and industrial and mining enterprises.

Main Features of the Electric Muffle Furnace:

· The furnace chamber of the electric muffle furnace is made of high-purity alumina fiber, which reduces energy loss.

· The furnace chamber of the electric muffle furnace is coated with a high-temperature alumina coating imported from the United States, which improves heating efficiency and service life.

· The electric muffle furnace is equipped with overheating and burnout protection, and a door-opening power-off function. The electric muffle furnace uses 1700-grade silicon-molybdenum rods, with a maximum temperature of 1700°C.

Technical parameters of the electric muffle furnace:

| Product Model | 1700°C High-Temperature small box furnace (8L) KSL-1700X-A2 |

| Technical Parameters | Power Supply of Electric muffle furnace: AC 220V/50Hz Power of Small box furnace: 5.2kW Heating Zone Dimensions: 200*200*200mm Maximum Operating Temperature: 1700°C (≤30min) Long-Term Operating Temperature: 1600°C Recommended Heating Rate: Room Temperature to 1400°C ≤10°C/min 1400-1600°C ≤5°C/min Above 1600°C ≤2°C/min Heating Elements: Silicon-Molybdenum Rods (6 pcs) |

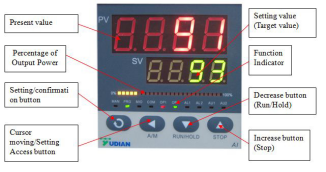

| Temperature Control System | Includes a YD858P Temperature Controller PID Automatic Temperature Control System Intelligent 50-Segment Programmable Control Temperature Control Accuracy: ±1°C Default DB9 PC Communication Port MET Certified Optional computer temperature control software (for the YD858P series controller) is available for controlling the heating curve and exporting data.

|

| Product Specifications | 550mm (L) * 660mm (W) * 800mm (H) Approximate weight: 125kg |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Warranty Period of Small box furnace:

This Small box furnace comes with a one-year warranty (excluding wear parts such as gaskets and heating elements).

The KSL series box furnaces offer the following features:

· 30-stage intelligent temperature controller with PID control and a temperature control accuracy of ±1°C

· Configurable upper temperature limit alarm, automatically shutting off the main circuit when the temperature exceeds the upper limit.

· High-purity oxidation furnace chamber material provides excellent thermal insulation. A variety of chamber sizes are available to meet various experimental requirements.

· RS232 port for communication with a computer (optional).

Introduction of Silicon Carbide Rod:

Silicon carbide (SiC) heating elements are made from green, high-purity hexagonal silicon carbide. They are manufactured through high-temperature siliconization and recrystallization at 2200°C. They are rod-shaped, non-metallic, high-temperature heating elements. They can operate at temperatures up to 1450°C and, under reasonable conditions, can last for over 2000 hours in air, without the need for a protective atmosphere. Compared to metal heating elements, these elements offer advantages such as high operating temperatures, oxidation and corrosion resistance, long life, minimal deformation, and easy installation and maintenance. Therefore, they are widely used in a variety of high-temperature furnaces and other heating equipment in industries such as electronics, magnetic materials, powder metallurgy, ceramics, glass, metallurgy, and machinery.

· We have many years of experience in the industry and a deep understanding of the industry and our products. Whether it's product quality or customer reviews, we surpass our peers.

· If you are interested in any product, please feel free to contact us for consultation.

· I believe our company can become your long-term and reliable supplier.