1200℃ Split-type Box Furnace (27L) KSL-1200X-M-F

1. Our Laboratory Heat Treatment Furnace can be used for experiments in ceramics and metal materials.

2. This Laboratory Heat Treatment Furnace can be used with a glove box or fume hood for more precise results.

3. This Laboratory Heat Treatment Furnace features a split design, allowing the power supply unit and heating element to be placed separately, which is particularly beneficial for certain experiments.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the Split High Temperature Furnace:

The split high temperature furnace features a separate furnace body and power supply unit. The heating element can be easily placed in a fume hood. This split high temperature furnace can be applied to annealing, sintering, fine debinding, degreasing, and corrosion and contamination control during material sintering processes in various fields such as ceramics, porous materials, and 3D printing.

Key features of the split high-temperature furnace:

1. The Laboratory Heat Treatment Furnace is a split design, with the furnace chamber and power supply box separate.

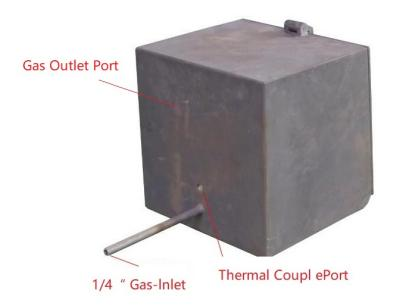

2. An air inlet is pre-installed on the back of the Laboratory Heat Treatment Furnace, located 10mm directly below the thermocouple.

3. An exhaust vent is pre-installed on the upper rear left side of the Laboratory Heat Treatment Furnace. The high-temperature resistant metal pipe for the air inlet is 10mm in diameter, and the high-temperature resistant metal pipe for the exhaust vent is 20mm in diameter. A chimney is built around the exhaust vent, with a base size of 60mm x 30mm, an upper size of 30mm x 30mm, and a length of 230mm.

Technical parameters of the Industrial muffle furnace:

| Product Model | 1200℃ Split-Type Glue Removal Oven (27L) KSL-1200X-M-F |

| Technical Parameters of Industrial muffle furnace | · Rated Power of split high temperature furnace (KW): 7.5KW · Power Supply of split high temperature furnace(V): AC220/50Hz · MAX Temperature (℃): 1200℃ · Rated Temperature (℃): 1100℃ · Recommended Heating Rate: ≤10℃/min · Thermocouple: Type K thermocouple · Heating Element: Molybdenum-doped iron-chromium-aluminum · Furnace Chamber Dimensions: 300X300X300mm · Temperature Control Accuracy (℃): ±1℃ |

| Metal Box | External Dimensions: 230*230*250mm 1. Material: Heat-resistant 314 alloy (AISI) / (DIN material number 1.4841); Continuous operating temperature: ≤1000℃ 2. Dimensions: 220*220*220 (internal dimensions), wall thickness 5mm. 3. Door Opening Method: Bottom-opening door with latch. A round hole is provided on the door for easy hooking of the furnace door. 4. The bottom of the front door, at the hinge, has an arc-shaped angle, 2 cm high. 5. A vent pipe (made of high-temperature resistant metal, 10mm in diameter, located 4 cm from the bottom, at the midpoint) is located slightly below the center of the back of the metal box. A 8mm diameter hole for a thermocouple is pre-drilled 10mm above the vent, corresponding to the thermocouple position.

|

| Electrical Controls | Temperature controller 1) 50-segment programmable temperature control. 2) Over-temperature alarm, deviation alarm, thermocouple failure alarm. 3) RS485 communication interface for PC connection, with accompanying temperature control software. 4) Type K thermocouple. 5) Overcurrent and overvoltage protection, leakage protection. All electrical components, cables, and cold-pressed terminals comply with UL certification standards. |

| Product Specifications | Dimensions: Furnace body: 640*560*670mm Power supply box: 645*560*300mm

|

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Benefits of choosing our Industrial muffle furnace:

The unique split design of the Industrial muffle furnace optimizes heat dissipation, reduces the temperature rise of the power supply box, and allows for flexible furnace placement during use. It improves the safety and convenience of the operating environment.

The Industrial muffle furnace has a wide range of applications, providing precise and stable temperature control for research, production, and laboratory use. For high-precision design processes, the high reliability of the equipment is crucial.

The industrial muffle furnace features a highly efficient temperature control system and advanced temperature control technology, precisely controlling temperature changes and avoiding uneven temperature distribution.

Shenyang Kejing boasts a strong reputation and accumulated experience in the industry. With many years of experience, we have served numerous well-known domestic and international enterprises, research institutions, and universities, maintaining long-term, positive customer relationships. Our clients' long-term cooperation and high praise are sufficient proof of the effectiveness of our products and the value of our brand.