1500℃ Mini Box Furnace (1.7L)

1. Our Mini Box Furnace uses carbon silicon rods as heating elements, resulting in rapid temperature rise and reduced experiment time.

2. This high-temperature Mini Box Furnace boasts high temperature control accuracy, providing greater precision and efficiency.

3. The Mini Box Furnace is constructed from high-purity alumina fiber, minimizing energy loss.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the Small Box Furnace:

The KSL-1500X-S is a high-temperature small box furnace. It utilizes silicon carbide rods as heating elements, a double-shell structure, PID programmable temperature control, and an S-type thermocouple. The small box furnace utilizes high-purity alumina fiber. Its maximum temperature can reach 1450°C, with a continuous operating temperature of 1400°C and a temperature control accuracy of ±1°C. The small box furnace offers advantages such as uniform temperature distribution, low surface temperature, and energy efficiency. It is ideal for high-temperature sintering, metal annealing, and quality inspection in universities, research institutes, and industrial and mining enterprises.

Main Features of the Mini Box Furnace:

·The furnace chamber of the high temperature box furnace is made of high-purity alumina fiber, minimizing energy loss.

·The furnace chamber is coated with a high temperature alumina coating imported from the United States, which improves heating efficiency and service life.

·The high temperature box furnace features overheating and burnout protection, as well as a door-opening power-off function. The high temperature box furnace features built-in air intake and exhaust ports to remove undesirable contaminants and moisture, extending the life of the heating elements and furnace.

Technical specifications of the high temperature box furnace:

| Product Model | 1500°C Mini Box Furnace (1.7L) KSL-1500X-S |

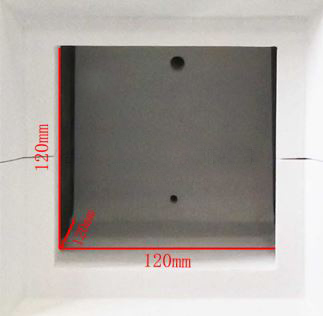

| Technical Parameters of Small Box Furnace | · Power Supply: AC 220V 50Hz · Power Consumption: 2.5kW · Heating Zone Dimensions: 120*120*120mm

· Maximum Temperature: 1450°C (≤ 1h) · Long-Term Operating Temperature: 1400°C (using Japanese brand heating elements); · Long-Term Operating Temperature: 1300°C (using domestic brand heating elements) · Recommended Heating Rate: ≤10°C/min below 1400°C, ≤5°C/min above 1400°C · Heating Elements: Silicon Carbon Rods (4 pcs) · Thermocouple: S-Type |

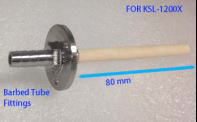

| Atmosphere of Small Box Furnace | Air inlets and outlets are located at the rear and top of the furnace, respectively, for introducing inert gas into the chamber. The air inlet is a 6mm diameter pagoda nozzle, and the air outlet is a 30mm diameter circular outlet.

|

| Temperature Control System | · Includes a YD858P temperature controller. · PID automatic temperature control system. · Intelligent 50-step programmable control. · Temperature control accuracy: ±1°C. · Default DB9 PC communication port. · MET certified. · Optional computer temperature control software (for the YD858P series controller) is available for controlling heating curves and exporting data.

|

| Specifications of High temperature box furnace | 380mm (L) * 410mm (W) * 620mm (H) Net weight of Mini box furnace: 50kg |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Warranty Period of Mini box furnace:

This Mini box furnace comes with a one-year warranty (excluding wear parts such as gaskets and heating elements).

Why choose our Small Box Furnace?

Our company has many years of experience in the industry and offers comprehensive pre-sales and after-sales service. Every industry, and even every small experiment, has its own unique characteristics, requiring different types of heating furnaces. While ensuring product quality, we have designed a variety of tube furnaces and box furnaces. These furnaces offer varying capacities, temperatures, and heating surfaces. We hope to find one that perfectly suits your specific needs. Furthermore, we hope to become your partner, jointly exploring new markets and building new partnerships in the materials preparation industry.