1400℃ Box Furnace (36L)

1. This heating muffle furnace boasts a maximum operating temperature of 1400°C, meeting most laboratory requirements.

2. Our heating muffle furnace fully considers actual temperature requirements and allows for precise control.

3. Our heating muffle furnace provides uniform heating and simultaneous temperature monitoring.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Laboratory Heat Treatment Furnace:

The KSL-1400X-A4 is a high-temperature laboratory heat treatment furnace. It utilizes silicon carbide rods as heating elements, a double-shell structure, PID programmable temperature control, and S-type thermocouples. The Laboratory Heat Treatment Furnace is constructed of high-purity alumina fiber. Its maximum operating temperature can reach 1400°C, with a continuous operating temperature of 1300°C and a temperature control accuracy of ±1°C. The Laboratory Heat Treatment Furnace offers advantages such as uniform temperature distribution, low surface temperature, and energy efficiency. It is ideal for high-temperature sintering, metal annealing, and quality inspection in universities, research institutes, and industrial and mining enterprises.

Key Features of the High-Temperature Laboratory Furnace:

· The high temperature laboratory furnace is large, reaching 36L.

· The high temperature laboratory furnace is made of high-purity alumina fiber, which reduces energy loss.

· The high temperature laboratory furnace is coated with a high-temperature alumina coating imported from the United States, which improves heating efficiency and service life.

· The high temperature laboratory furnace is equipped with overheating and thermal insulation protection, and features a door-opening power-off function.

· The high temperature laboratory furnace includes a temperature sensor for real-time monitoring of the furnace chamber temperature and an overheating alarm, ensuring safe operation.

· The high temperature laboratory furnace has built-in air intake and exhaust ports to remove undesirable contaminants and moisture, extending the service life of the heating elements and chamber.

Technical Parameters of the Heating Muffle Furnace:

| Product Model | 1400°C Heating muffle furnace (36L) KSL-1400X-A4 |

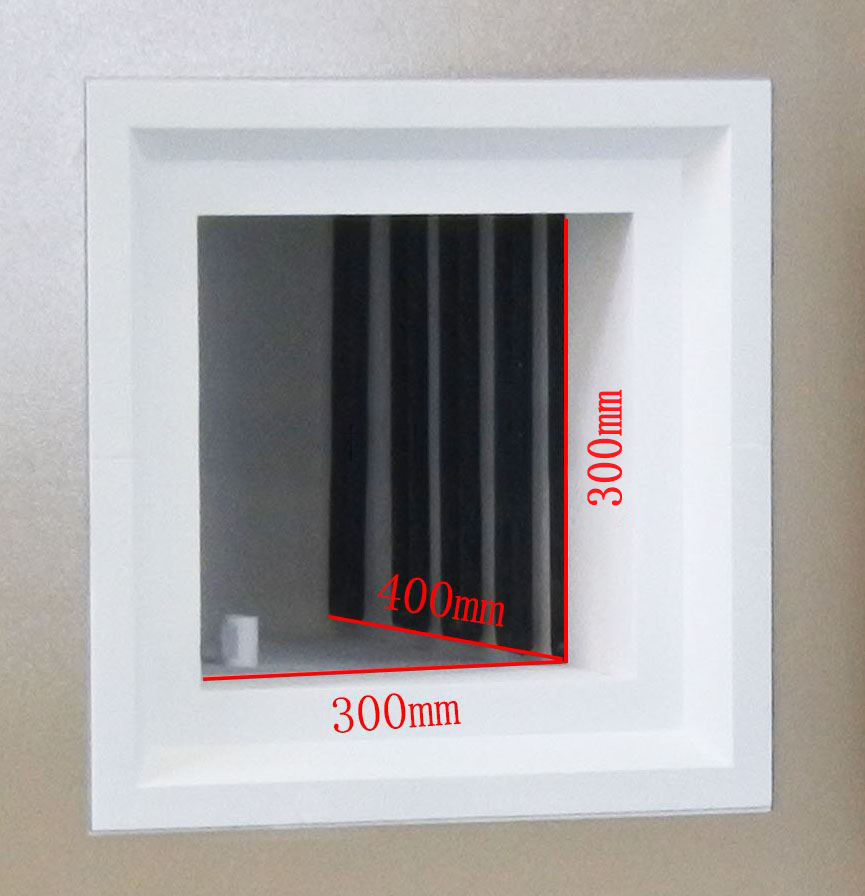

| Technical Parameters | Power supply: AC220V/50Hz Power consumption: 10kW Heating zone dimensions: 300*400*300mm Power supply: AC220V/50Hz Power consumption: 10kW Heating zone dimensions: 300*400*300mm

|

| Atmosphere | · Air inlet: φ6.35 compression fitting (left side), air intake is controlled by a float flow meter on the front panel, with a flow range of 16-160 ml/min; · Air outlet: An air outlet is located at the top (the air outlet is a circular outlet with an outer diameter of 40 mm and an inner diameter of 30 mm). |

| Temperature Control System | Includes a YD858P temperature controller; PID automatic temperature control system; Intelligent 50-segment programmable control; Built-in overheat protection and thermocouple fault alarm; Temperature control accuracy: ±1°C; Default DB9 PC communication port; Optional computer temperature control software (for the YD858P series controller) for controlling the heating curve and exporting data.

|

| Specifications | 760mm (L) * 700mm (W) * 1020mm (H) Weight: Approximately 280kg |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Warranty period of Heating muffle furnace:

Laboratory Heat Treatment Furnace has 1 year (excluding wear parts such as gaskets and heating elements).

Usage Precautions of Heating muffle furnace:

When operating, first understand the temperature tolerance of the material. Different materials have different high-temperature resistances. Excessively high temperatures can cause deformation, melting, or damage. Therefore, when setting the temperature, ensure that the ambient temperature does not exceed the material's tolerance range.

About our advantages:

1. Independent R&D and manufacturing capabilities:

Shenyang Kejing has independent R&D and production capabilities. All technologies are developed internally by the company to ensure product quality and technological leadership.

2. Efficient customer service:

The company focuses on customer needs, provides customized solutions, and can quickly respond to customers' technical support needs to improve customer experience and satisfaction.

3. Strong industry experience:

Shenyang Kejing has accumulated rich experience in multiple industry fields, especially in high-precision equipment and technological innovation, helping customers improve production efficiency and technical level.