1200℃ Laboratory Box Furnace

1. Our Alumina Fiber Chamber Furnace utilizes alumina fiber, which improves heating efficiency and enhances lab productivity.

2. This Alumina Fiber Chamber Furnace features overheat protection and a door-opening power-off function, greatly enhancing safety.

3. If certain parameters of this Alumina Fiber Chamber Furnace are not suitable for you, you can also view our other chamber furnaces with different temperature limits and parameters, or contact us directly for more information.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of the Compact Chamber Furnace:

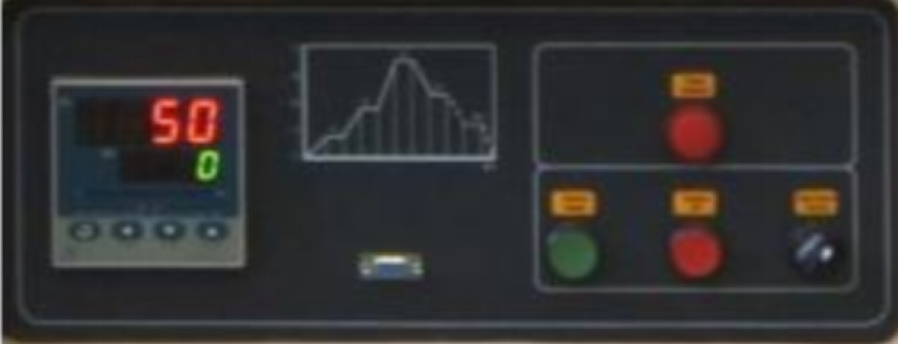

The KSL-1200X-N Compact Chamber Furnace uses resistance wire as the heating element, features a double-shell structure, 50 programmable temperature control, and a K-type thermocouple. The furnace chamber is constructed of high-purity alumina fiber. It has a maximum temperature of 1200°C and a continuous operating temperature of 1100°C, with a temperature control accuracy of ±1°C. The Compact Chamber Furnace offers a uniform temperature field, low surface temperatures, fast temperature ramping, and energy savings. It is ideal for high-temperature sintering, metal annealing, and quality inspection in universities, research institutes, and industrial and mining enterprises.

Features of the Laboratory Compact Chamber Furnace:

· The door stopper and furnace door are integrated, making it easy to remove samples and even open the door for sample placement at high temperatures.

· The furnace chamber of the Laboratory Compact Chamber Furnace is made of high-purity alumina fiber, minimizing energy loss.

· The furnace surface of the Laboratory Compact Chamber Furnace is coated with a high-temperature alumina coating imported from the United States, improving heating efficiency and service life.

· The furnace chamber of the Laboratory Compact Chamber Furnace features built-in air intake and exhaust ports to remove undesirable contaminants and moisture, extending the service life of the heating elements and furnace.

· The Laboratory Compact Chamber Furnace is equipped with overheating and burnout protection, and a door-opening power-off function.

· The furnace chamber of the Laboratory Compact Chamber Furnace is heated from three sides, ensuring a fast heating rate and a uniform temperature distribution.

Technical Parameters of the Laboratory Compact Chamber Furnace:

| Product Name | 1200℃ Laboratory Compact Chamber Furnace |

| Model | KSL-1200X-N |

Basic Specifications

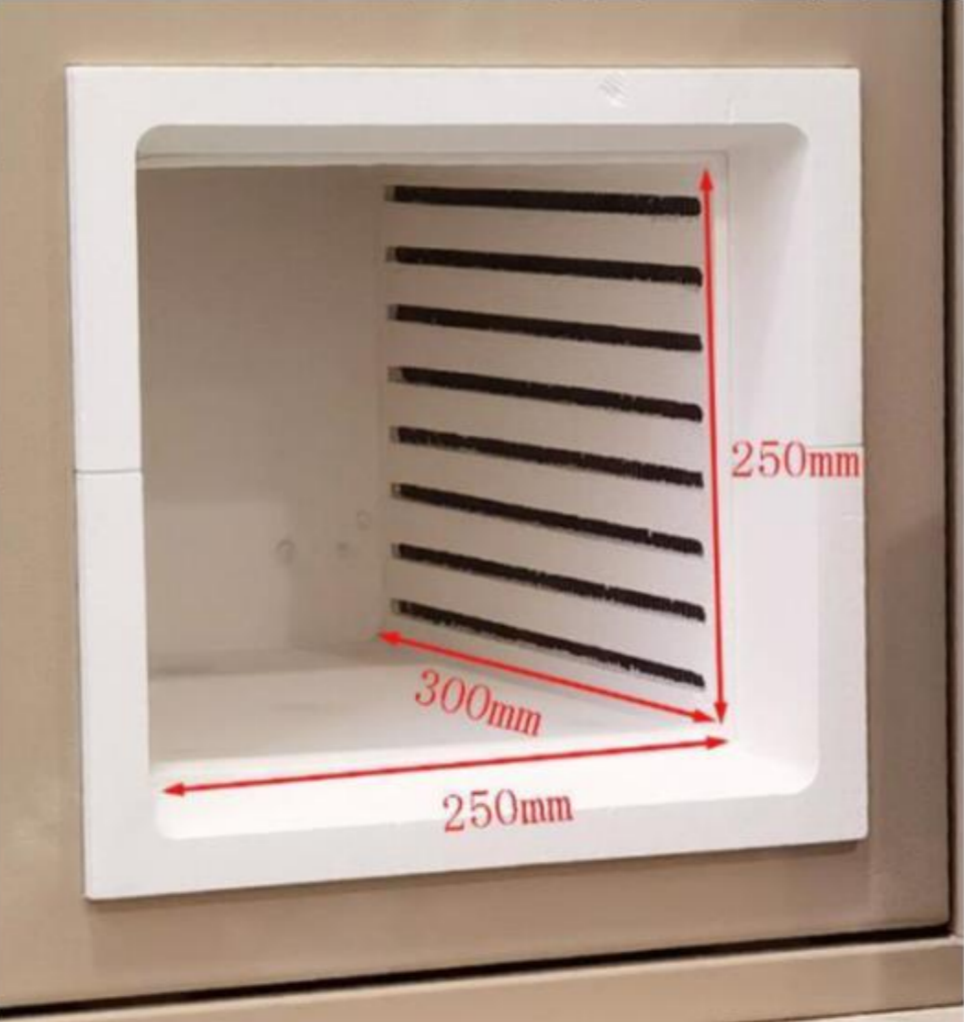

| Power Supply of Alumina Fiber Chamber Furnace: AC 220V/50Hz Power of Alumina Fiber Chamber Furnace: 6.5kW Furnace Dimensions: 250*300*250mm (L/D/H) Maximum Operating Temperature: 1200°C (≤30 minutes) Sustainable Operating Temperature: 1100°C Heating Element: Resistance Wire (Molybdenum-doped Iron-Chromium-Aluminum Alloy) Recommended Heating Rate: ≤10°C/min Thermocouple: Type K

|

Embedded Resistance Wire Furnace Lining (Optional)

| Features: Low pollution, corrosion resistance Power supply: AC 220V/50Hz Rated power: 6.5kW Furnace dimensions: 250*300*250mm (length, depth, height) Temperature: Maximum operating temperature: 1100°C (≤30 minutes); Operating temperature: 900°C Heating rate: ≤10°C/min (recommended heating rate to improve equipment life) Heating element: Resistance wire (molybdenum-doped iron-chromium-aluminum alloy) Thermocouple: Type K |

| · Includes an 858P temperature controller (optional Eurotherm instrument for a constant temperature accuracy of ±0.1°C) · PID automatic temperature control system · Intelligent 50-segment programmable control · Default DB9 PC communication port · Temperature control accuracy: ±1°C · All electrical components are UL or MET recognized and have passed other relevant safety tests worldwide. · Optional PC temperature control software is available for controlling temperature curves and exporting data.

|

| Air Inlet and Outlet | The furnace has an air inlet and outlet at the rear and top, respectively, for introducing inert gas into the chamber. The air inlet is a 6.35mm diameter dual-ferrule connector, and the air outlet is a 30mm diameter circular outlet.

|

| Dimensions | Dimensions: 550*600*800mm (length*width*height)

|

| Weight | About 90kg |

| Shelf Life | 1 year (excluding consumable parts such as furnace tubes, Viton O-rings, and heating elements). |

| Precautions | · The equipment must operate on an independent power grid within a ±8% voltage range. It must not share a power grid with high-magnetic-field generating equipment, such as medium-frequency or high-frequency equipment, and must not be located in the same room as such equipment. If this is not possible, please conduct harmonic testing and control on the power grid and implement electromagnetic isolation on the equipment. · We do not recommend the use of flammable, explosive, or toxic gases. If your process requires the use of flammable, explosive, or toxic gases, please implement appropriate protective and explosion-proof measures. Our company assumes no responsibility for any problems caused by the use of flammable, explosive, or toxic gases. · Keep the equipment away from areas where liquids may splash. · Keep the equipment away from magnetic and conductive powders. · The insulation and heating elements are consumable parts. Cracks in the insulation material during sintering are normal and can be repaired with a repair agent. The heating elements are consumable parts. If the furnace fails to reach operating temperature or heats up noticeably slowly after extended use, contact the manufacturer to determine whether they need to be replaced. · It is not recommended to operate the furnace above 500°C. |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Precautions for Using the Alumina Fiber Chamber Furnace:

Do not touch the interior or exterior of the Alumina Fiber Chamber Furnace during operation or for a period after use to prevent burns.

Do not place vases, bonsai, cups, cosmetics, medicines, or metal objects on the Alumina Fiber Chamber Furnace. Dropping them could cause injury.

Do not damage the power cord; a damaged power cord can cause fire, electric shock, and other accidents.

Why choose us:

· We have a strong reputation in the industry.

· We have been innovating in this field for many years and have numerous clients and positive reviews.

· We are confident in the quality and effectiveness of our products.

Contact us today!