News

Shenyang Kejing Auto-instrument Co., Ltd. is invited to participate in the much-anticipated Asia Photonics Expo (APE) 2025, which will be held at Marina Bay Sands Singapore from February 26 to 28, 2025. We are very prepared and look forward to meeting friends who will be attending the exhibition together!

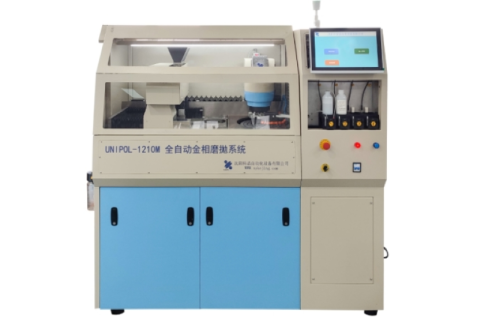

In materials science research, the efficiency and accuracy of the metallographic sample preparation process directly affect the reliability of experimental results. In order to meet the needs of scientific research institutions and industrial laboratories for automation, precision and consistency, we have developed a device called "UNIPOL-1210M fully automatic metallographic grinding and polishing system", which not only provides a highly integrated sample preparation solution, but also can cover a series of full-process automated operations such as mounting, grinding, polishing and cleaning. Let's take a look at how the automatic grinding and polishing machine performs at work!

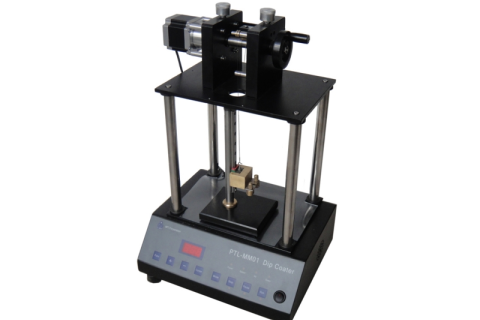

Our Shenyang Kejing's PTL-MM01 programmable dip coater uses a self-developed high-precision single-chip control system, which can provide precise and stable control capabilities. The lifting speed and stroke of the equipment can be set according to needs, and it maintains smooth and accurate operation during operation. In addition, users can also adjust the lifting direction through manual buttons to achieve more flexible operation. So how can we make good use of the lifting coating machine to complete the work tasks more efficiently?

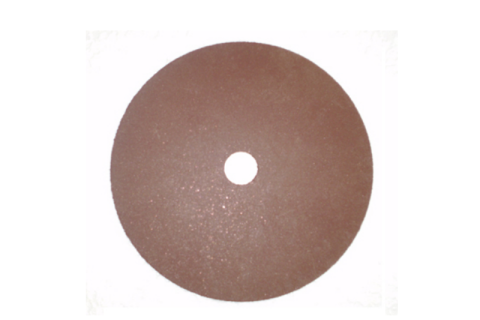

In metal cutting, it is very important to choose the right saw blade material. Different metal types, hardness and cutting conditions require different saw blade materials to ensure cutting efficiency and tool life. Therefore, how to choose the most suitable metal cutting saw blade material has become a key issue in the processing industry. This article will analyze several common metal cutting saw blade materials in detail, with special emphasis on materials suitable for high hardness and high precision requirements, to help you make a wiser choice.

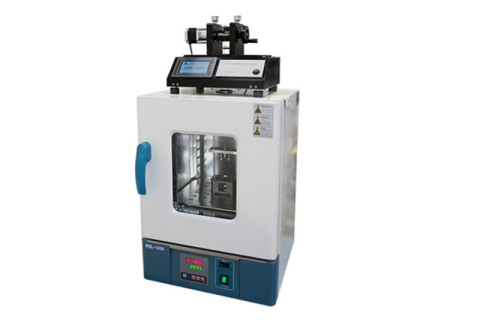

In modern material research and semiconductor manufacturing, thin film preparation and coating technology are crucial. Especially in the field of thin film coating with nanometer precision, PTL-NMB nanometer grade thermostatic dip coater, as a precision equipment, has become an important tool in research and industrial applications. This article will introduce in detail how to use PTL-NMB nanometer puller to coat silicon wafers.

In order to meet the high-precision requirements of scientific research institutes and corporate laboratories in the field of thin film material preparation, we have developed a PTL-UMB micron grade thermostatic dip coater. This high-precision equipment with CE certification is designed for immersion and pulling coating experiments in liquid phase.

Recently, we have launched a new product: Tem wedge grinding and polishing fixture. It can be mainly used in semiconductor materials (section, plane), ceramic materials, metal materials, composite materials, etc. To shorten the thinning time. Our product has three major technical highlights. You all know it. Let us take a look at it together!

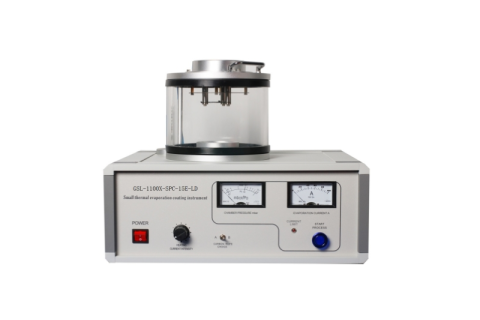

As we said before, we will continue to innovate and develop new products, and we will continue to do so in the future, so today we bring you the latest product, the small evaporation coating machine, which is designed for carbon evaporation coating on the surface of small laboratory samples and is widely used in scanning electron microscope (SEM) sample preparation. In the design process, we took into account the convenience of users, so the small evaporation coating machine has a small and exquisite, efficient vacuum performance and simple and convenient operation. So do you want to know how it actually plays its value? Let me give you a detailed introduction below.

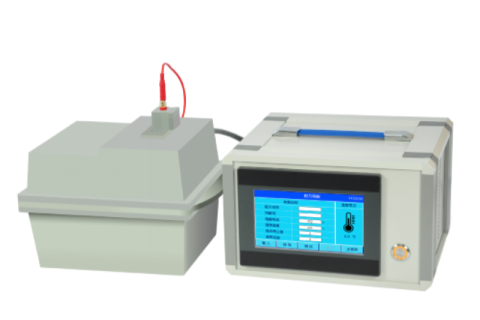

In the precise world of scientific research, transmission electron microscope sample preparation is a crucial link. The intelligent and visual technical advantages of TJ100-SE automatic twin jet electropolisher provide an efficient and stable sample preparation method for thinning metal electron microscope samples.

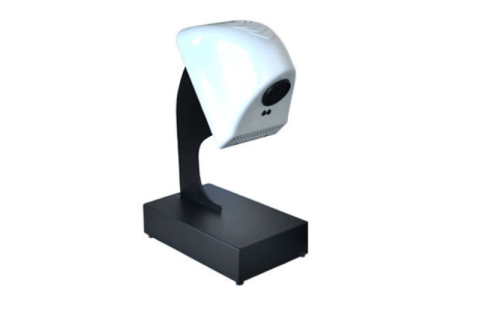

In the daily work of the materials laboratory, the rapid drying of samples and the hygienic cleaning of hands are often the focus of researchers. And a drying device that is both efficient, hygienic and convenient is quietly becoming the "new favorite" of the laboratory. Laboratory induction automatic dryer, this intelligent device tailored for the materials laboratory, is redefining the standard of laboratory drying tools with its excellent design and performance.