News

Industry status: The market is gradually placing higher requirements on the high precision and high efficiency of coating machines, and is gradually developing towards miniaturization, high efficiency and intelligence. Its application in the electronics industry and new energy fields is also increasing.

Event details: Exhibition: Asian Photonics Expo (APE 2025). Date: February 26-28, 2025. Venue: Marina Bay Sands, Singapore. Booth number: C113. Company name: Shenyang Kejing Auto-instrument Co., Ltd. Click the link to register and enjoy VIP audience treatment: Link: https://reg.asiaphotonicsexpo.com/en/index.html?ly=EN-EInvitation2025-Email-C113

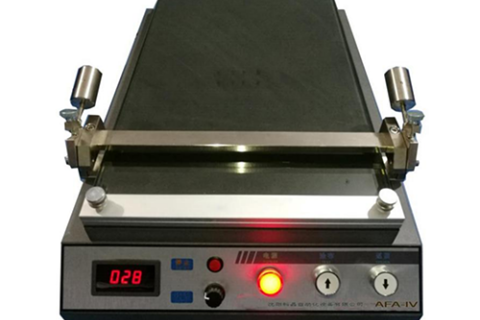

Can meet diverse needs: Coating machine is small in size and more suitable for scenes such as laboratories. It is also suitable for a variety of materials. In the daily storage of coating machine for stepless speed, the environment should be dry, dust-free, and well-ventilated, avoiding direct sunlight or high temperature and high humidity areas.

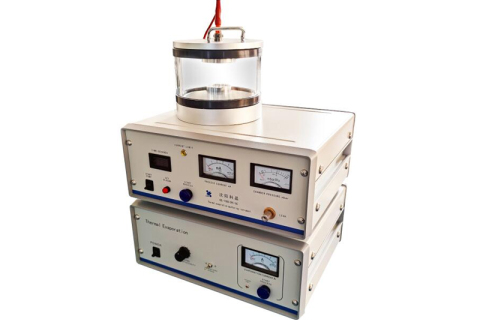

Three Target Plasma Sputtering Coater is a high-tech device widely used in materials science, physics research and other fields. To ensure that users can use this device correctly and effectively, the following is a detailed usage method:

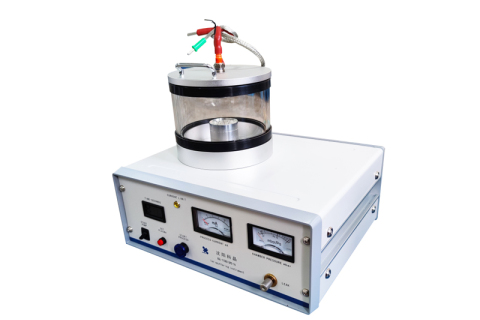

In the field of modern materials science and microscopic analysis, plasma sputtering technology is widely used in thin film deposition. Our Single Target Plasma Sputtering Coating Machine is efficient and accurate in practical applications. It also simplifies the operation of operators with its high performance, laying a foundation in the industry.

Electron microscope technology continues to advance, and scanning electron microscopes (SEM) are increasingly used in materials science, biology, and nanotechnology. In order to ensure the quality of SEM images, high-quality metal or carbon film coatings are required during sample preparation. Traditional coating equipment often faces problems such as complex operation and uneven film layers, which brings a lot of trouble to scientific researchers. How to improve the efficiency and convenience of sample preparation while ensuring the quality of the film layer has become the focus of attention of relevant staff.

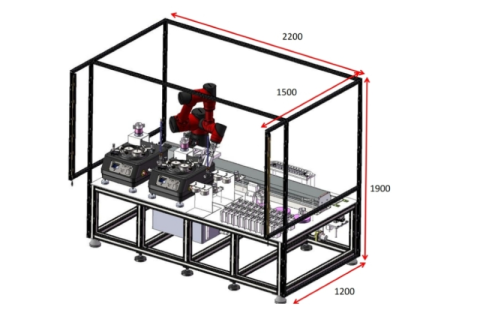

In order to improve the automation level of laboratory sample preparation, Shenyang Kejing Automation Instrument Co., Ltd. has developed an intelligent grinding and polishing equipment that integrates a collaborative robot and a multi-functional operating platform to achieve efficient, precise and automated operations. The following is the detailed usage process of robotic grinding and polishing workstation:

Compared with the previous one, this peach shaped hole workpiece fixing tool has been upgraded. This sample tray has three stations and is designed for UNIPOL series precision grinding and polishing machines. It can provide more efficient and stable grinding and polishing effects. First of all, let's understand what is the "outstanding feature" of this product?

In order to enrich the cultural life of employees and enhance team cohesion, Shenyang Kejing successfully held the "2024 Employee Fun Sports Meeting". With the theme of winter enthusiasm, this sports meeting set up five interesting events: tug of war, double rope skipping, table tennis, hooping, and darts. It attracted the active participation of the company's employees and injected infinite vitality and laughter into the cold winter.

Shenyang Kejing recently launched a new equipment: "UNIPOL-1220S automatic grinding workstation", which brings a new user experience to users with its fully automated and intelligent design and optimization of functions and operations. Next let us learn about it together!