Precision Grinding and Polishing Controller

1. This Grinding and polishing controller can perfectly control the flatness and parallelism of the sample surface.

2. The Grinding and polishing controller can grind and polish samples that require high precision.

3. The Grinding and polishing controller has excellent technology and high quality, and is suitable for use in a variety of scenarios.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Polishing Controller:

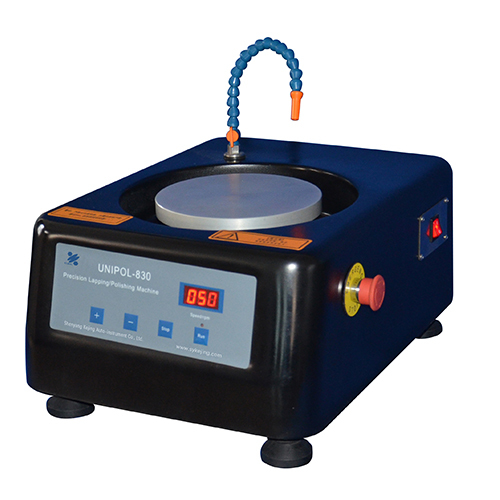

GPC-150A Precision grinding and polishing controller is referred to as Grinding and polishing controller. It is mainly used to control the flatness and parallelism of the surface of the sample being ground, so that the sample after grinding and polishing has high dimensional accuracy and excellent surface quality. Polishing Controller is made of high-quality stainless steel material, with beautiful appearance and exquisite manufacturing process. It is mainly suitable for UNIPOL-1502 grinding and polishing machine. It is an indispensable precision grinding and polishing tool for grinding and polishing workpieces. Polishing Controller is especially suitable for grinding wafer samples and large disc-shaped samples with high requirements for surface parallelism and flatness. The GPC-150A Polishing Controller special sample block is connected to the controller with a thread. The sample clamping method is vacuum adsorption, and it is equipped with a digital thickness gauge, which can monitor the reduced thickness of the sample in real time. The maximum diameter of the sample is 6 inches, and it has the advantage of high process repeatability.

Advantages of Polishing Controller:

Automatic grinding and polishing equipment can strictly control the parallelism and flatness of the surface of the sample being ground, and the control accuracy is high. During the grinding process, it can be used with a digital thickness gauge to observe the sample grinding amount at any time. Automatic grinding and polishing equipment is especially suitable for grinding wafer samples with high requirements for surface parallelism, flatness and sample thickness.

Technical parameters of automatic grinding and polishing equipment:

| Product Name | GPC-150A Precision Grinding and Polishing Controller |

| Product Model | GPC-150A |

| Installation Conditions | 1. This equipment is required to be used at a temperature of 25℃±15℃ and a humidity of 55%Rh±10%Rh. 2. Water: water distribution source. 3. Electricity: None. 4. Gas: vacuum pump (0— -0.1MPa). 5. Dimensions: φ146mm×266mm 6. Ventilation device: required. |

| Main parameters | 1. Sample tray diameter: Ø162mm 2. Sample tray axial travel: ≥12mm 3. Digital display accuracy: 0.001mm 4. Adjustable loading pressure of sample tray: 0.1kg-4.6kg 5. Effective range of pressure confirmation instrument: 1g-5000g 6. Sample loading method: vacuum adsorption 7. Loading sample size: diameter ≤155mm 8. Overall dimensions: φ198mm×295mm |

Standard accessories of the product:

| NO. | Name | Quantity | Image link |

| 1 | Vacuum pump | 1 set | - |

| 2 | Filter bottle | 1 set | - |

| 3 | Base | 1 piece | - |

| 4 | Glass sheet | 3 pieces | - |

About us:

We are not only an equipment supplier, but also a provider of scientific research services. We serve the society with innovative technology, always put customers' needs first, and are committed to providing customers with the best solutions. We pursue excellence and strive to become a well-known brand of domestic materials analysis instruments and win respect and trust in the international market. When you choose Shenyang Kejing, you will choose a dynamic and progressive partner.