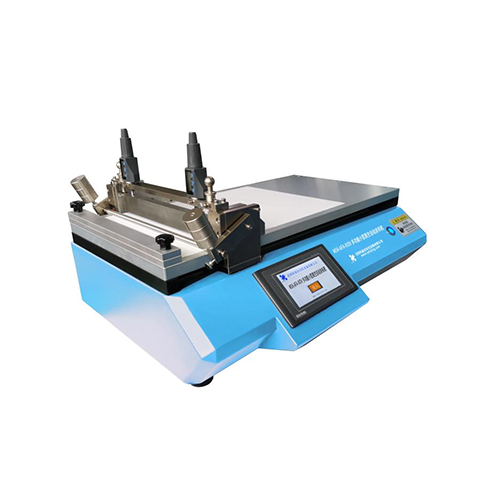

Multifunctional Small Vacuum Automatic Coating Machine

1. Our vacuum coating unit is made more durable with high-quality components.

2. If you're hesitant about the higher prices of other competitors, feel free to contact us. We offer affordable prices while guaranteeing the quality and effectiveness of our vacuum coating unit.

3. We have conducted hundreds of experiments on the vacuum coating unit itself, achieving precise coating results under various conditions.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of vacuum coating unit:

The MSK-AFA-IVDV multi-functional small vacuum coating unit uses all high-quality components at a competitive price, making it popular with many multinational corporations' R&D institutions and numerous renowned universities both domestically and internationally. Vacuum coating equipment ensures coating effect, uniformity, and stability by controlling speed and maintaining stable pressure. The biggest advantage of vacuum coating equipment is its ability to perform coating experiments on various flat materials such as paper, plastic, metal, PVC, PET, fabric, and aluminum alloy plates. The biggest advantage of the MSK-AFA-IVDV vacuum coating equipment is its ability to repeatedly and continuously produce smooth, flat, and flawless test samples. This allows researchers to precisely coat different substrates, reducing or eliminating errors caused by human factors such as varying coating speed and pressure. The coating head uses a stainless steel U-shaped scraper, mimicking a large coating machine head to ensure that the experimental product matches the quality of the production coating. The coating head can be quickly opened 90 degrees for easy cleaning of the scraper after each experiment.

Key features of the lab vacuum coating equipment:

· The coating thickness can be adjusted by changing the coating roller.

· The coating speed is adjusted via a knob and displayed on a screen.

· All components of our lab vacuum coating equipment are imported.

· The lab vacuum coating equipment enables uniform coating, further improving project results.

Technical parameters of the lab vacuum coating equipment:

| Product Name | MSK-AFA-IVDV Multifunctional Small Vacuum Automatic Coating Machine | |

| Product Model | MSK-AFA-IVDV | |

| Main Parameters | 1. Power Supply: 220V 50HZ | |

| 2. Total Power: 48W (Standby), 2000W (Heating) | ||

| 3. Coating Uniformity: ±5% | ||

| 4. Effective Coating Size: 300*450mm (Sample fixed using vacuum method) | ||

| 5. Coating Thickness: 0.005-5mm (Wet film) (Variations vary depending on the viscosity of the adhesive; actual testing shall prevail) | ||

| 6. Squeegee Material: Alloy steel (Heated squeegee optional; heating temperature: room temperature - 180 degrees Celsius) | ||

| 7. Speed: 1-10 meters/minute | ||

| 8. Heating Temperature: Room temperature - 200 degrees Celsius | ||

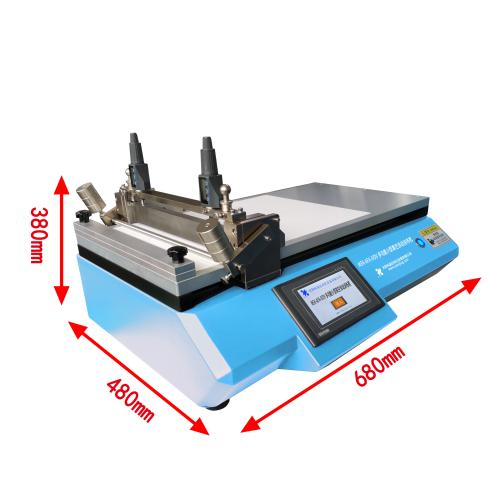

9. Product Specifications: · Dimensions: 680*480*380mm · Weight: 38kg |  | |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. | |

Optional Accessories of vacuum coating unit:

| No. | Name | Function Category | Image Link |

| 1 | Adjustable coating applicators are available upon request, with a minimum thickness of 5μm and an adjustment accuracy of 1μm. | (Optional) | - |

| 2 | Coating rollers are available with coating thicknesses of 5μm, 10μm, 15μm, 20μm, 25μm, 30μm, 40μm, 50μm, 60μm, 80μm, 100μm, 120μm, 150μm, and 200μm. | (Optional) | - |

Operating Instructions for Lab Vacuum Coating Equipment:

1. Prepare Coating Material: Place the solution or slurry to be coated into the reservoir of the vacuum coating unit and convey it to the coating head.

2. Adjust Vacuum Coating Unit Parameters: Adjust parameters such as the pressure of the coating head, the position and angle of the doctor blade, etc., according to the characteristics of the coating material and substrate. Alternatively, change the coating head to adjust the coating thickness and adjust the coating speed using the knob.

3. Start the Vacuum Coating Unit: Feed the substrate into the machine, start the machine, and begin coating.

4. Check Quality: Regularly check the coating quality to ensure the thickness and uniformity of the coating.

5. Drying: After coating, send the substrate into the drying chamber for drying.

6. Shut Down the Lab Vacuum Coating Equipment: After drying, shut down the vacuum coating unit and remove the substrate for subsequent processing. Ensure safety and thoroughly clean the inside of the machine.

About Our Services:

We have focused on the research and design of laboratory equipment for many years, possessing superior technology and rich experience. Regarding flatbed coating machines, we have years of R&D experience, and our equipment has significant advantages in precision, stability, and efficiency.

Our coating machines are suitable for coating various types of films, meeting the refined production needs of different customers.

Our company provides you with a dedicated one-on-one technical support team, offering comprehensive after-sales service.

Choosing our company means more than just purchasing a product; it means receiving comprehensive technical support and service.

Let us help you improve production efficiency, reduce maintenance costs, and drive business growth.