Chemical Mechanical Polishing Machine

1. The grinding part is made of anti-corrosion materials, the chemical mechanical grinding and polishing machine can last in chemical environments and reduce maintenance costs.

2. The chemical mechanical grinding and polishing machine has two processing stations, which can be independently controlled.

3. The chemical mechanical grinding and polishing machine is equipped with a touch screen panel, which is easy to operate, precise and efficient.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

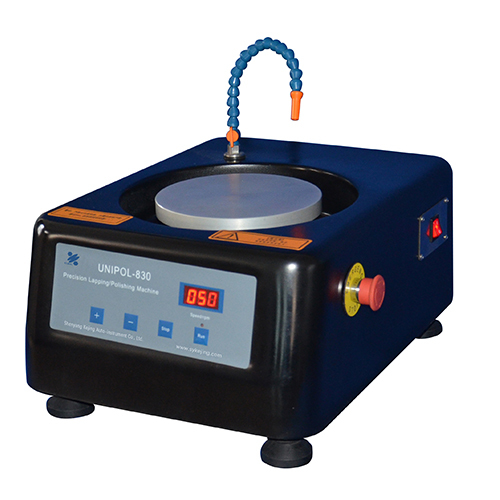

Introduction of chemical mechanical grinding and polishing machine:

UNIPOL-1203 chemical mechanical grinding and polishing machine is suitable for CMP flattening and smoothing process technology. The grinding part of the whole machine is made of anti-corrosion materials and is resistant to chemical corrosion. The chemical mechanical grinding and polishing machine is equipped with an automatic dripper and precision grinding and polishing controller, and a fully automatic touch screen panel. It can meet the needs of wafer and other surface processing in terms of processing performance and speed.

Main features of fully automatic chemical mechanical polishing machine:

1. Ultra-flat stainless steel polishing disc (flatness is less than 0.0025mm per 25mm×25mm).

2. Ultra-precision rotary axis (tray end jump is less than 0.01mm).

3. The fully automatic chemical mechanical polishing machine has two processing stations, which can be controlled separately.

4. The chemical mechanical grinding and polishing machine is equipped with a fully automatic control touch screen panel, which can set the spindle speed, swing arm speed, and grinding and polishing time.

5. The fully automatic chemical mechanical polishing machine is equipped with an automatic drip feeder, flow rate visual adjustment, automatic grinding and polishing.

6. The fully automatic chemical mechanical polishing machine is equipped with a GPC-100A precision grinding and polishing controller, which can adjust the pressure and trim the surface shape, making grinding and polishing more convenient and quick.

7. The grinding part of the fully automatic chemical mechanical polishing machine is made of anti-corrosion materials and is resistant to chemical corrosion.

Technical parameters of auto chemical mechanical polishing machine:

Product Name | UNIPOL-1203 Chemical Mechanical Grinding and polishing Machine / Lapping Machine |

Product Model | UNIPOL-1203 |

Installation Conditions | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) temperature: 5-45℃. 2. There is no strong vibration source and corrosive gas around the auto chemical mechanical polishing machine. 3. Power supply: Single phase: AC220V 50HZ national standard three-pole socket 10A (the socket must have a good safety protection grounding wire). 4. Cooling water: The equipment is equipped with a water inlet and a water outlet, and you need to connect the tap water and drainage pipeline or circulation filtration system by yourself. 5. Workbench: It is recommended to use the auto chemical mechanical polishing machine on a workbench or desktop with a load-bearing capacity of more than 200kg. 6. Ventilation device: In a good ventilation environment, the auto chemical mechanical polishing machine does not require special ventilation devices. 7. Other auxiliary equipment (need to be purchased separately): |

Main Parameters (Specification) | Parameters of the grinding and polishing machine: 1. Power supply port of auto chemical mechanical polishing machine: AC220V 50HZ. 2. Total power: 500W (MAX). 3. Diameter of grinding and polishing disc: φ300 mm, 1 cast iron disc and 1 stainless steel flat disc. 4. Diameter of sample plate: φ105, 1 ceramic flat sample plate and 1 ceramic repairing ring. 5. Number of stations of auto chemical mechanical polishing machine: 2. 6. Main drive motor: Precision servo motor 0.45kW. 7. Swing arm drive motor: DC reduction motor DC24V 0.8W. 8. Rotation speed of lower grinding and polishing disc: 1-240rpm (adjustable speed). 9. Swing arm speed gear: 1-15 gears adjustable. 10. Control mode of auto chemical mechanical polishing machine: Touch screen. 11. Overall dimensions of auto chemical mechanical polishing machine: L550×W700×H420mm. 12. Net weight: ≈82kg. |

GPC-100A precision grinding and polishing controller (manipulator): 1. Sample plate diameter: Ø103mm. 2. Sample plate axial travel: 12mm. 3. Digital display accuracy: 0.001mm. 4. Adjustable loading pressure of sample plate: 0.1kg-2.0kg. 5. Effective range of pressure confirmation instrument: 1-5000g. 6. Sample loading method: vacuum adsorption. 7. Loading sample size: diameter ≤103mm, thickness ≤12mm. 8. Overall dimensions: outer diameter Φ146mm, height 266mm. | |

SKZD-2 dripper (drum stirring): 1. Equipment power supply port: DC24 2.5A (standard power adapter IN: AC100-240V OUT: DC24V 2.5A). 2. Volume: 1.5L. 3. Dropping method: physical dropping by barrel rotation. 4. Flow rate: 0-35ml/min (stepless speed regulation). 5. Drive motor: DC reduction motor: DC24V 10W. 6. Overall dimensions: L290×W170×H350mm. | |

SKZD-4 automatic dripper (suspension): 1. Equipment power supply port: DC12 2A (standard power adapter IN: AC100-240V OUT: DC12V 2A). 2. Dropping station (dropping pump): 4 (1-4 position conversion dripping). 3. Liquid bottle volume: 500ml/bottle. 4. Drive control mode: precision stepper motor + peristaltic pump + single board computer controller. 5. Dropping method: peristaltic quantitative dripping. 6. Flow rate: 0.1ml/min-10ml/min (speed adjustable). 7. Operation mode: timed operation: range: 1-999min. 8. Dimensions: L230×W370×H450mm. | |

AP-1400V oil-free vacuum pump: 1. Equipment power supply port: AC220V 50Hz 450W. 2. Max air flow: 7.2m³/h. 3. Max vacuum degree: -700mmHg (-91KPa). 4. Noise: ≤60db. 5. Thermal protector: automatic reset 130℃±5℃. 6. Dimensions: L204×W125×H181mm. |

Standard accessories:

No. | Name | Qty | Picture |

1 | Cast Iron Grinding Plate (Ф300mm) | 1 pcs | |

2 | Stainless Steel Grinding Plate (Ф300mm) | 1 pcs | |

3 | Sample Holding Plate (ceramic) | 1 pcs | |

4 | Condition Ring (ceramic) | 1 pcs |

|

5 | Polishing Pad (Nubuck Leather, Synthetic Leather, Polyurethane) | 1 pcs each | |

6 | Magnetic Sheet (with adhesive on the back) | 2 pcs |

|

7 | (Steel) Lapping Buffer Sheet | 2 pcs |

|

8 | Corundum Grinding Powder | 0.5kg | |

9 | Wax Bar | 4 pcs |

|

10 | Silica Suspension Polishing Fluid 2040 W0.05 | 1 bottle |

|

Optional accessories:

No. | Name | Functional type | Picture |

1 | YZXZ-12 Stirring Circulation Pump | (optional) |

|

2 | Precision Thickness Gauge | (optional) | |

3 | Ceramic Lapping Plate | (optional) | |

4 | Glass Lapping Plate | (optional) | |

5 | Magnetic Resin Diamond Polishing Sheet | (optional) |

|

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions).

Logistics:

About us:

In order to better serve our customers, we have established a high-quality customer service center. Customers can bring samples to our company and conduct trial processing in our dedicated laboratory, which will help customers understand the performance of our products. Our company's professionals can also provide, so that customers can buy the most suitable equipment.