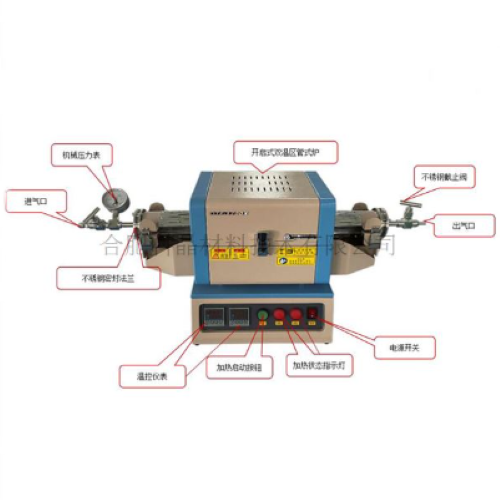

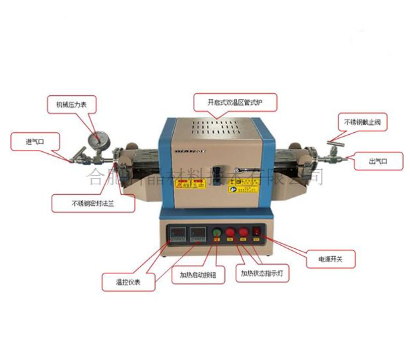

1200°C Small Dual Zone Open Tube Furnace (Optional 1"- 2" Quartz Tube & Flange)

1. The two heating zones of compact split tube furnace can independently set the temperature rise and fall program, easily create a gradient temperature field or conduct comparative experiments, compact split tube furnace can meet complex process needs.

2. The standard configuration of compact split tube furnace provides 1-inch or 2-inch (optional) high-purity quartz tube and stainless steel flange. Compact split tube furnace is suitable for different sample volumes and atmospheric environment requirements.

3. Compact split tube furnace integrates an intelligent program temperature control system, supports multi-stage program temperature rise and fall, simple operation, high repeatability, and reduces the threshold for personnel operation.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of high temperature tube furnace:

Compact split tube furnace OTF-1200X-S-II is a CE-certified small dual-temperature zone open tube furnace. The Max high operating temperature of compact split tube furnace can reach 1200℃. The furnace tube of compact split tube furnace is a high-purity quartz tube with a diameter of 25mm or 50mm. The compact split tube furnace is equipped with a set of stainless steel sealing flanges. The compact split tube furnace can heat treat samples in a vacuum or atmosphere-protected state. Compact split tube furnace has two heating zones with a heating length of 100mm, and the Max constant temperature gradient of the two temperature zones is 200℃. If the same temperature program is set in the two temperature zones, a 100mm constant temperature zone can be obtained. The two temperature control systems independently control the two temperature zones, and both can set a 50-stage heating program, with a temperature control accuracy of ±1℃.

The main features of high temperature tube furnace:

· Open type vacuum tube furnace adopts double-layer shell structure.

· High temperature tube furnace uses high-purity alumina fiber as the furnace material, and the surface is oiled with alumina coating, which can improve heating efficiency and extend service life.

· High temperature tube furnace has two 4-inch long heating zones, which can independently control the temperature.

· High temperature tube furnace is compact in size and compact in structure.

· Alumina circular partitions are optional between the dual heating zones of the high temperature tube furnace, which can help you establish a temperature gradient in the furnace tube.

· All electronic components of high temperature tube furnace are UL certified.

· High temperature tube furnace can purchase quartz tube plug and quartz crucible, which can increase the cleanliness and vacuum in the furnace tube.

Technical parameters of open type vacuum tube furnace:

| Product Name | 1200°C Small Dual Zone Open Tube Furnace (Optional 1"- 2" Quartz Tube & Flange) OTF-1200X-S-II |

| Basic Parameters | · Power supply: AC 110V 50HZ/60hz (standard 110V to 220V transformer) · Power: 1.2KW · Max high temperature: 1200℃ (<1h) · Continuous working temperature: 1100℃ · Recommended heating rate: ≤10℃/min · Thermocouple: type K · Heating element: ferromolybdenum-chromium-aluminum doped · Heating zone length: 200mm |

| Quartz Tube Size (Optional) | · Φ25 x 600mm · Φ50 x 600mm |

| Sealing Flange | · High temperature tube furnace is sealed with a pair of ss304 stainless steel vacuum flanges and high temperature silicone sealing rings · The two needle valves have been installed on the two flanges separately · A vacuum pressure gauge is mounted on one side flange |

| Stainless Steel Sealing Flange System | · A set of water-cooled sealing flanges, between the sealing flange and the corundum pipe flange, a compression silicone O-ring sealing method is used. · The upper flange adopts clamps to facilitate sampling and pipe blocking. The upper flange is equipped with a precision needle valve, a pointer vacuum pressure gauge and a 6.35 double card sleeve air inlet. · The lower flange has a KF25 air outlet and a pagoda mouth air outlet. · Lofting: the upper flange has a sample hook for hanging samples, and the lower flange can also be reserved with a sample placement platform. (Customers need to communicate with the sales before purchasing, whether the sample is hung or placed on the sample stage, and the hanging temperature exceeds 1200℃. Customers need to purchase platinum wire by themselves). |

| Flange Accessories (Optional) | · The flange is equipped with a φ8 pagoda nozzle connector. In order to obtain a better pumping rate, you can choose to use a KF25 adapter. · In order to better pass gas into the furnace tube, a 1/4" stainless steel sleeve joint can be selected. · KF25 vacuum port flange can be purchased. · Flange bracket can be purchased. |

| Temperature Control System | · The two temperature zones of high temperature tube furnace are controlled by two independent temperature control systems · High temperature tube furnace includes a YD858P type temperature controller · PID automatic temperature control system · Intelligent 50-segment programmable control · Temperature control accuracy: ±1℃ · Default DB9 PC communication connection port · Passed MET certification · Optional computer temperature control software (for YD858P series controllers) is used to control the heating curve and export data |

| Temperature Calibration (Optional) | · Regularly calibrate the temperature of the open type vacuum tube furnace to maintain the accuracy and uniformity of the temperature. You can purchase a simple calibration kit from our company to assist you in this task. The complete calibration kit includes: 1. 48"L (1/4"O.D) K-type thermocouple calibration 2. An OMEGA temperature calibrator 3. Thermocouple compensation line |

| Vacuum System | · Model: VRD-8 · Pumping rate: 2.2L/S · Motor power: 370 W · Ultimate pressure: 5×10-1Pa (without load) · In order to obtain a higher degree of vacuum, you can choose other high vacuum systems of our company · A cold vacuum trap can be purchased to avoid pollution caused by the vacuum pump |

| The Size of the Open Type Vacuum Tube Furnace | · Dimensions when closed: 900 L x 330 W x 390H mm · Dimensions when turned on: 900 L x 440 W x 540 H mm · The length in the size includes the length of the furnace tube and flange |

| The Net Amount of Open Type Vacuum Tube Furnace | About 18Kg |

| Quality Assurance of Compact Split Tube Furnace | One-year warranty, lifetime technical support. Special note: 1. Consumables such as heating elements, quartz tubes, sample crucibles, etc. are not included. 2. Damage caused by the use of corrosive and acid gases is not covered by the warranty. |

| Quality Certification of Open Type Vacuum Tube Furnace | · Open type vacuum tube furnace has passed CE certification · Certificate number: M.2021.206.C67997 · If the customer pays the certification fee, the company guarantees that a single open type vacuum tube furnace will pass the German TUV certification or CAS certification. |

| Precautions for Use | · The air pressure in the quartz tube should not be higher than 0.02MPa (relative air pressure). · Due to the high air pressure inside the gas cylinder, a pressure reducing valve must be installed on the gas cylinder when introducing gas into the quartz tube. In order to ensure safety, it is recommended to use a pressure lower than 0.02MPa. It is recommended to purchase a pressure reducing valve from our company. The range of the company's pressure reducing valve is 0.01MPa-0.1MPa, which will be more accurate and safe when used. · For sample heating experiments, it is not recommended to close the exhaust valve and intake valve at the flange end of the furnace pipe. If you need to close the valve to heat the sample, you need to pay attention to the number of pressure gauges at all times. If the number of pressure gauges is greater than 0.02MPa, the vent valve must be opened immediately to prevent accidents (such as broken furnace pipes, flanges flying out, etc.). · We do not recommend that customers use flammable, explosive and toxic gases. If the customer does need to use flammable, explosive and toxic gases for technical reasons, please take relevant protective and explosion-proof measures by yourself. The company is not responsible for related problems caused by the use of flammable, explosive and toxic gases. |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

FAQ:

Q: What are the main considerations for choosing a 1-inch or 2-inch quartz tube for open type vacuum tube furnace?

A: The choice of quartz tube for open type vacuum tube furnace mainly depends on your sample size, required atmosphere flow and working pressure. The 1-inch tube is suitable for powder or small-size samples with small air consumption. The 2-inch tube is suitable for larger samples or scenarios that require a higher atmospheric flow rate.

Why choose us:

1. We focus on the field of laboratory automation and material preparation equipment, understand the real needs of scientific research and industrial users, and design products closer to practical applications.

2. From the selection of core components to the assembly and commissioning of the whole machine, we implement strict quality standards, and every equipment that leaves the factory has reliable performance and long life.

3. We provide detailed operation guidelines and fast after-sales response. Our team of engineers can provide professional technical advice for your special application needs.