- Home

- >

- News

- >

- Industry News

- >

News

Recently, we have launched a new product: Tem wedge grinding and polishing fixture. It can be mainly used in semiconductor materials (section, plane), ceramic materials, metal materials, composite materials, etc. To shorten the thinning time. Our product has three major technical highlights. You all know it. Let us take a look at it together!

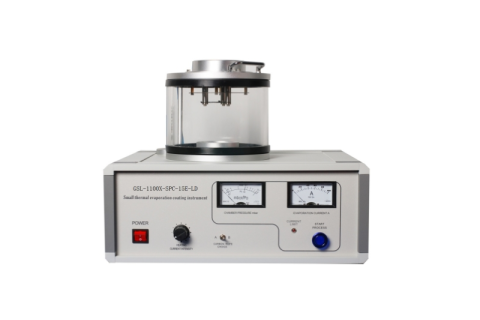

As we said before, we will continue to innovate and develop new products, and we will continue to do so in the future, so today we bring you the latest product, the small evaporation coating machine, which is designed for carbon evaporation coating on the surface of small laboratory samples and is widely used in scanning electron microscope (SEM) sample preparation. In the design process, we took into account the convenience of users, so the small evaporation coating machine has a small and exquisite, efficient vacuum performance and simple and convenient operation. So do you want to know how it actually plays its value? Let me give you a detailed introduction below.

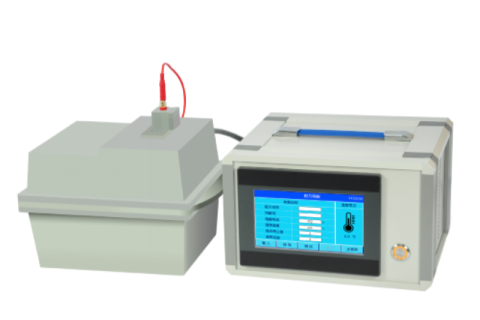

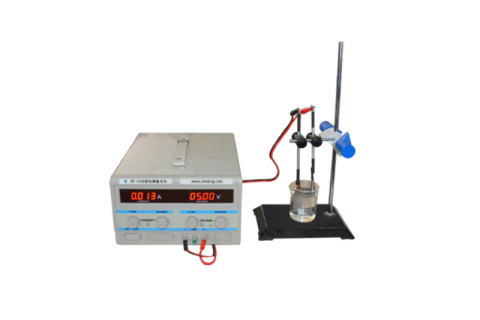

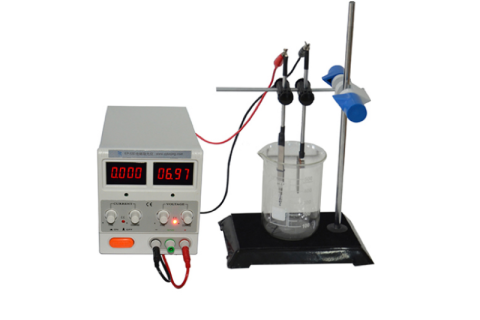

In the precise world of scientific research, transmission electron microscope sample preparation is a crucial link. The intelligent and visual technical advantages of TJ100-SE automatic twin jet electropolisher provide an efficient and stable sample preparation method for thinning metal electron microscope samples.

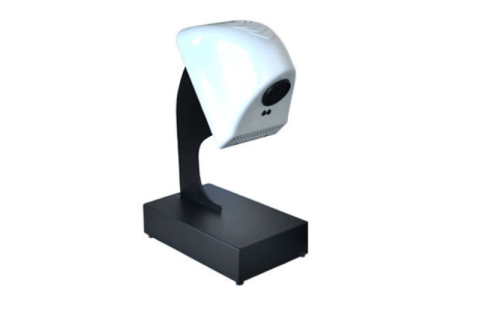

In the daily work of the materials laboratory, the rapid drying of samples and the hygienic cleaning of hands are often the focus of researchers. And a drying device that is both efficient, hygienic and convenient is quietly becoming the "new favorite" of the laboratory. Laboratory induction automatic dryer, this intelligent device tailored for the materials laboratory, is redefining the standard of laboratory drying tools with its excellent design and performance.

I believe that before buying ultrasonic spray pyrolysis coater, you will have several questions, such as what factors should I consider? What is "suitable"? What kind of ultrasonic spray pyrolysis coater should I choose to maximize its value in my work. Please join me in exploring how to buy the ultrasonic spray pyrolysis coater that is truly suitable for you!

1. Cutting speed of electroplated diamond saw blade: Electroplated diamond saw blade is made of diamond particles electroplated on a metal matrix. It has high hardness and wear resistance and is suitable for cutting stone, building materials and other fields. Its cutting speed is affected by many factors, such as cutting materials, saw blade size, rotation speed, etc.

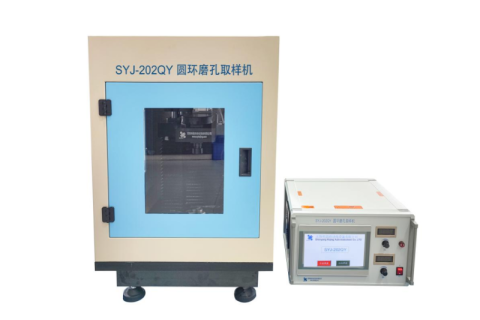

In the field of modern materials science and engineering, high-precision sample preparation is the basis for successful experiments. However, for the preparation of cylindrical or annular samples of some crystals, ceramics, glass, metals and other materials, traditional equipment often faces problems such as insufficient sampling accuracy, low efficiency and high sample loss. In response to these pain points in production, Shenyang Kejing independently developed and launched the SYJ-202QY ring grinding sampler. With its superior technical performance and wide applicability, the equipment provides integrated solutions for related industries. Let’s experience its charm together!

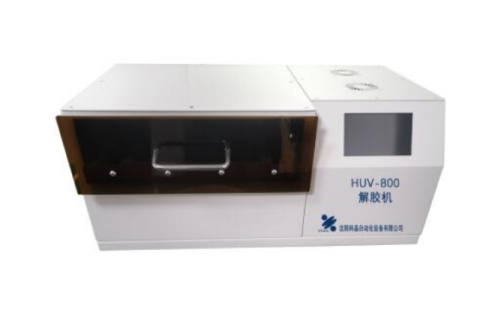

UV LED debonding machine is a common equipment in the curing industry, which has many unique features and advantages. In this article, we will explore the application areas of UVLED debonding machine and its outstanding features.

The EP-1060 electrolytic polisher has become an indispensable tool in metallographic specimen preparation due to its excellent functionality and portability. However, in order to better utilize the equipment performance, while ensuring the safety of laboratory personnel and the long-term use of the equipment, it is particularly important to operate and maintain the equipment correctly. The following are key considerations for the operation and maintenance of electrolytic polishers and etchers for metallography. Let's take a look!

In the fields of industry and scientific research, high-precision cutting is an indispensable part of the material preparation process. In response to the difficult needs of cutting super-hard materials such as crystals, ceramics, glass, and cemented carbide, shenyang kejing has launched a new edge-sintered diamond saw blade. The sintered diamond saw blade sinters 4mm to 7mm wide diamonds on the edge of the steel substrate. Micro powder and metal composite materials, so why is it said to be a cutting tool? Sintered diamond saw blade has the following advantages:

The iterative upgrade of laboratory equipment is not only a technological advancement, but also the key to improving scientific research efficiency and quality. Today, we bring you a groundbreaking device - EP-530 electrolytic etching machine. Whether in the laboratory or in the field, the electrolytic etching machine can become an ideal assistant for metallographic sample preparation with its excellent performance and portable design. Next, let's explore the powerful functions of this device together!

In order to ensure the efficient operation and safe use of the YLJ-60TH manual protective press, Shenyang Kejing has carefully compiled common troubleshooting methods and precautions for manual laboratory hydraulic press for users to help users quickly solve problems and extend the service life of the equipment.