- Home

- >

- News

- >

- Industry News

- >

News

With the rapid development of modern industry, the importance of the product has gradually been reflected. This equipment is also widely used in industries such as pharmaceuticals, electronics and materials science. These industries also have high requirements for the drying and curing of sensitive materials. The Laboratory drying oven we produce fully meets the high demands of these industries and can help customers achieve high-performance production or experiments.

The emergence and application of sputtering technology has gone through many stages. After more than 30 years of development, magnetron sputtering technology has developed into an irreplaceable method for optical, electrical and other functional thin films.How much do you know about them?

On the basis of basic magnetron sputtering,high vacuum and high temperature growth environment are introduced, and plasma technology is combined to improve the reaction efficiency of reactive deposition, so as to realize magnetron sputtering film epitaxy. The film prepared under this high vacuum condition has a better lattice orientation and more outstanding crystal properties. It has a wide range of applications in superconducting quantum, ferroelectric materials, piezoelectric materials, thermoelectric materials and other fields. The high vacuum state helps to reduce the influence of impurities and ensure that the sputtered particles do not react adversely with other gases during the deposition process.

APE 2025 is one of the largest and most influential advanced materials and energy technology exhibitions in Asia, bringing together the world's top companies and scientific research institutions. At the exhibition, our booth welcomed hundreds of visitors, including professionals from well-known universities, scientific research institutes and enterprises, and we became one of the focuses of the exhibition.

Uneven thin films will lead to experimental data deviation and affect the accuracy of research results. Traditional film coating technology is easily affected by operating techniques, equipment accuracy and environmental factors, and it is difficult to achieve uniform coating over a large area.

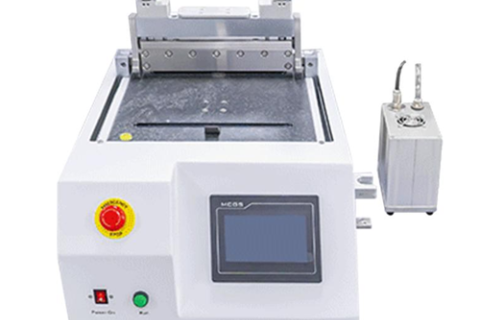

The new generation of Flame assisted spray pyrolysis machine has unique advantages: high efficiency, accuracy and precision. High-level coating deposition technology provides a better choice for multiple fields. Combining high efficiency and precision: The product adopts advanced spray pyrolysis technology to achieve rapid decomposition and deposition. Through this advantage, the product can greatly improve the uniformity and adhesion of the coating to meet the different needs of different application scenarios.

New energy, flexible electronics, biomedicine and other fields are developing faster and faster. As one of the core processes, precision coating technology is facing new challenges. For coating technology, higher requirements are placed on the accuracy, stability and material adaptability of equipment. Traditional equipment still has many problems in terms of uniformity and adaptability, which makes it difficult to meet the needs of scientific research institutions or enterprises.

Industry status: The market is gradually placing higher requirements on the high precision and high efficiency of coating machines, and is gradually developing towards miniaturization, high efficiency and intelligence. Its application in the electronics industry and new energy fields is also increasing.