Precision Polishing Fixture For Dia.100mm Sample

GPC-100A Precision Grinding and Polishing Controller (lapping controller for short), is mainly used to control the flatness and parallelism of sample surface, so that the polished sample has high dimensional accuracy and excellent surface condition.It is mainly suitable for using in UNIPOL-1202 and UNIPOL-1502 grinding and polishing machines.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The GPC-100A Precision Grinding and Polishing Controller (hereinafter referred to as the grinding and polishing controller) is primarily used with our UNIPOL series precision grinding and polishing machines. It is designed to control the flatness and parallelism of the surface of the workpieces being polished, ensuring high dimensional accuracy and excellent surface quality after grinding and polishing.

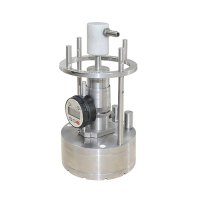

This series of precision grinding and polishing controllers is made of high-quality stainless steel. The bottom wear-resistant plate is evenly equipped with twelve wear-resistant elements, and the wear-resistant plate is designed as a non-wearing structure during the process. A pressure spring is installed between the pressure adjustment nut and the floating shaft, allowing precise control of the downward pressure by adjusting the spring compression. Workpieces are mounted using a vacuum suction method and equipped with a digital thickness gauge (digital micrometer) to monitor the material thinning parameters in real time. The load capacity is: workpiece diameter up to 4 inches, thickness ≤12 mm.

This product offers high process repeatability and strong compatibility. During operation, the surface of the workpiece to be polished always remains parallel to the wear-resistant elements, ensuring flatness while precisely controlling parallelism. It supports synchronous grinding and polishing of workpieces of different materials and flatness levels, with accurate thickness control. It is especially suitable for precision workpieces such as wafers and geological thin sections.

Main Features

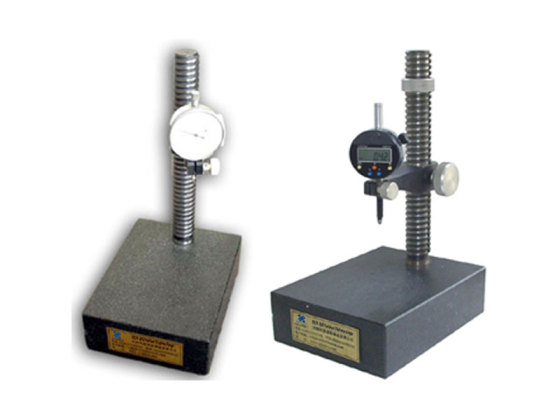

The parallelism and flatness of sample surface can be strictly controlled with high control accuracy. During the grinding process, it can be used with a digital thickness gauge to observe the reduced thickness of the sample at any time. It is especially suitable for grinding wafer samples with high requirements on surface parallelism, flatness and thickness.

Technical Parameters

Product Name | GPC-100A Precision Grinding and Polishing Controller | |

Product Model | GPC-100A | |

| Installation Requirements | 1. Temperature and humidity: 10–85% RH (non-condensing at 25℃), temperature: 5–45℃. 2. The area around the equipment should be free of strong vibrations and corrosive gases. 3. Water supply: A clean water source must be available on site. 4. Air supply: Vacuum pump with a maximum vacuum of -700 mmHg (-91 kPa) and a maximum airflow of 7.2 m³/h. 5. Ventilation: A well-ventilated environment is required; no special ventilation equipment is needed. | |

Main Parameters (Specification) | 1. Sample holder diameter: Ø103 mm 2. Axial travel of the sample holder: ≥12 mm 3. Adjustable loading pressure of the sample holder: 0.1–2.0 kg 4. Effective range of the pressure gauge: 1–5000 g 5. Thickness measuring instrument (digital micrometer): resolution 0.001 mm, range 0–12.7 mm (Max) 6. Sample mounting method: vacuum adsorption 7. Supported sample size: diameter 4 inches, thickness ≤12 mm | |

Product Dimension | Dimension: outer diameter:146mm, height: 266mm Weight::about 7 kg |

|

Auxiliary Equipment | 1. AP-1400V Oil-free Vacuum Pump 2. SCA-301 Pressure Gauge (Electronic Scale) 3. 500 ml Polypropylene Filter Bottle with Base and Rubber Stopper 4. Thickness Measuring Instrument (Digital Micrometer 0–12.7 mm, 0.001 mm resolution) 5. Sample Glass Slides 6. HEATER-250/3040 Series Heating Platform (Optional Purchase) | |

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics