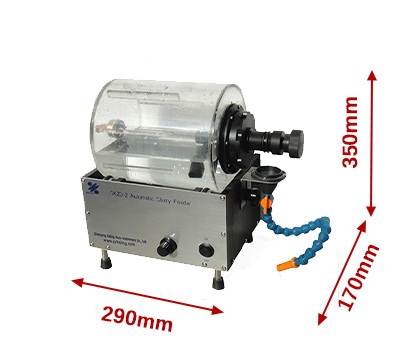

Automatic Slurry Feeder for Feeding Abrasive

SKZD-2 Slurry Feeder is used in conjunction with UNIPOL series lapping machine. When working, the internal stirring paddle rotates continuously to stir the liquid abrasive, which can effectively prevent the abrasive from precipitation. Therefore, SKZD-2 slurry feeder is especially suitable for abrasives that do not form suspension liquid in water, and the feeding speed can be adjusted during the working process.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

The SKZD-2 Drip Feeder is designed to work in conjunction with the UNIPOL series grinding and polishing machines. During operation, the internal stirring paddle continuously rotates, effectively preventing slurry sedimentation by keeping liquid abrasives well mixed. This makes the SKZD-2 particularly suitable for abrasive suspensions that do not readily form stable mixtures in water.

The drip rate is adjustable, allowing for automated and precise control of abrasive feeding throughout the grinding process. This not only reduces manual intervention and abrasive consumption, but also ensures uniform delivery of slurry, resulting in even abrasive distribution on the sample surface and significantly improving surface grinding quality.

Compact and simple in structure, the SKZD-2 can be placed directly on top of a grinding and polishing machine, saving workspace. It operates quietly and cleanly, with no environmental pollution during use.

Main Features

1. The abrasive feeding speed adopts stepless speed regulation.

2. Suitable for abrasives that are easy to precipitate in water

3. The feeding amount is uniform.

Technical Parameters

Product Name | SKZD-2 Slurry Feeder | |

Product Model | SKZD-2 | |

| Installation Conditions | 1. Temperature & Humidity: 10–85% RH (at 25°C, non-condensing); Temperature range: 5–45°C. 2. Environment: The surrounding area should be free from strong vibrations and corrosive gases. 3. Power Supply: Single-phase AC 100–240V, 50/60Hz, standard 2-pin/3-pin 10A socket (the socket must have a reliable safety ground connection). 4. Operation: Recommended for use on a workbench or tabletop. 5. Ventilation: Good general ventilation is required; no special ventilation system is necessary. | |

Main Parameters (Specification) | 1. Power Supply Port: DC 24V, 2.5A (standard power adapter: Input AC 100–240V, Output DC 24V, 2.5A) 2. Effective Barrel Volume: ≤1.5 L 3. Dripping Method: Physical dripping via rotating barrel 4. Barrel Rotation Speed: 0–30 rpm 5. Flow Rate: 0–35 mL/min (stepless adjustment) 6. Drive Motor: DC gear motor, DC 24V, 10W | |

Product Dimension and Weight | Dimension: 170mm×290mm×350mm Weight: 3kg |

|

Logistics