MSK-AFA-W800-AL Large Flatbed Coating Machine

1. Our thin film coating machine uses precision clicks to precisely control the coating speed, ensuring guaranteed results.

2. Our thin film coating machine is equipped with a scraper stopper, allowing for flexible control of coating length.

3. With years of R&D experience in this field and a comprehensive after-sales service system, you don't have to worry about subsequent issues with the thin film coating machine being unresolved.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Thin Film Coating Machine:

The MSK-AFA-W800-AL large thin film coating machine is primarily used for coating liquid or colloidal thin films in the laboratory. It utilizes a precision stepper gearbox motor to precisely control the coating speed, ensuring a uniform blade speed. The roller scraper is constructed entirely of stainless steel, effectively reducing friction between the scraper and the vacuum cup during movement, improving coating consistency and uniformity. The Lab thin film coating machine uses a bottom-mounted vacuum to hold the sample. The machine features a scraper stopper, allowing for flexible adjustment of the film length. The roller scraper automatically stops when the limit is reached.

This Lab Automatic Film Coating Machine is specifically designed for coating various thin films, such as lithium battery electrode films, various ceramic films, and polymer films.

Features of the Automatic Film Coating Machine:

·This automatic film coating machine utilizes a precision stepper gearbox motor and a PLC to precisely control the coating speed.

·The automatic film coating machine utilizes an all-stainless steel roller scraper, effectively reducing friction between the scraper and the vacuum suction cup during movement.

·A waste collection box, located on the left side of the vacuum suction plate, collects excess coating, ensuring cleanliness of the automatic film coating machine and the surrounding area.

Technical Parameters of the Automatic Film Coating Machine:

| Product name | MSK-AFA-W800-AL Large lab automatic film coater |

| Model | MSK-AFA-W800-AL |

| Installation requirements | Operating Environment of lab automatic film coater: Humidity: 10-85% RH (at 25°C non-condensing) Temperature: 0-45°C. 1. Water: Not required. 2. Power of lab automatic film coater: DC 24V 5A. 3. Air: Vacuum (vacuum pump). 4. Workbench of lab automatic film coater: Recommended dimensions: 2000 × 1000 × 500 mm; load-bearing capacity: 250 kg or more. 5. Ventilation: No special requirements. |

| Main parameters | 1. Power Supply of lab automatic film coater: DC 24V 5A (Actual power is subject to the label attached to the machine) |

| 2. Total Power of lab automatic film coater: Approximately 4000W | |

| 3. Vacuum Cup Dimensions (L x W): Approximately 1700mm x 850mm (Actual dimensions subject to actual product) | |

| 4. Effective Coating Area (L x W): 1600mm x 800mm | |

| 5. Vacuum Cup Planarity Accuracy: ±0.05mm | |

| 6. Coating Speed of lab automatic film coater: 500-5000mm/min | |

| 7. Coating Length: 1-1600mm (Adjustable) | |

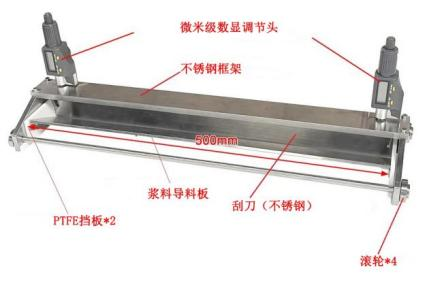

8. Rolling Squeegee: Se-KTQ-800: Standard Coating Width: 800mm; Film Thickness Adjustment Range: 0-5000µm; PTFE baffle to prevent slurry leakage; Squeegee frame equipped with four rollers for easy movement of the film former. Equipped with two digital micrometers with an adjustment accuracy of 3µm.

| |

| 9. Equipped with heating function (upper flip-top heating structure, maximum heating temperature 120°C, heating power 4000W). | |

| 10. Dimensions (L×W×H): 1800mm×850mm×500mm (estimated dimensions, actual dimensions subject to actual product). | |

| Note: The actual power supply of the device is subject to the label attached to the rear of the product. | |

| Compliance | CE Certified, UL or CSA certification is available at extra cost. |

Our Advantages:

Process and Equipment Integration:

We specialize in the simultaneous development of coating processes and equipment, ensuring stable coating thickness, excellent edge control, and low surface defect rates.

Customization Capabilities:

Due to the unique needs of each partner, specific customization requirements and differentiated options require in-depth discussion with our sales staff.

Digitalization and Automation:

Equipped with a digital display and precision motors, our coating system precisely controls the coating speed and automatically maintains a constant speed.

Delivery and Service:

Project-based delivery with clear milestones. We offer remote guidance during installation and commissioning, spare parts service, and remote diagnostics, minimizing downtime and maintenance costs.