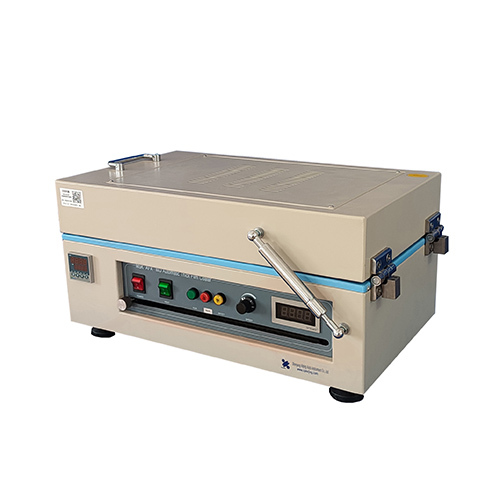

Compact Tape Casting Film Coater With Heatable Vacuum Bed

MSK-AFA-IIID Compact Casting Coater with automatic drying function adopts bottom heating and is designed and developed by our company.The equipment adopts the bottom vacuum to absorb the samples, and has bottom heating function. The heating temperature can reach up to 120℃, and the function of film baking is realized during the coating process, so that the film can be dried quickly.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Description

The MSK-AFA-IIID Small-Scale Automatic Casting and Drying Coater is a bottom-heating type automatic film casting machine independently designed and developed by our company. It is mainly used in laboratories for coating liquid or colloidal films. The unit adopts a stepless variable-speed motor to precisely control coating speed, ensuring uniform blade movement during the coating process. The doctor blade is made of stainless steel with constant weight, which improves coating consistency and uniformity.

The equipment uses bottom vacuum suction to secure samples and is equipped with a bottom heating system with a maximum heating temperature of 120 ℃, enabling simultaneous coating and drying for rapid film solidification. The MSK-AFA-IIID features a blade limiter, allowing adjustable coating length; once the blade reaches the limit, it automatically resets. The upper cover serves as dustproof and thermal insulation, while also enhancing the overall appearance.

This small-scale automatic film casting and drying coater is carefully designed to help operators apply high-quality wet films on different substrates, significantly improving coating repeatability.

Main Features

1. The equipment adopts a stepless variable speed motor to precisely control coating speed.

2. The adjustable doctor blade is driven by a horizontal bar, and there is no special requirements for the size of the adjustable doctor blade.

3. The waste collection box placed on the left edge of the vacuum chuck can collect excessive paint to ensure the cleanliness of the equipment itself and the surrounding area.

4. The intelligent vacuum heating chuck and the drying system with digital display temperature control can adapt to the development of coating technology under high temperature conditions.

5. Bottom heating is adopted and film baking is performed during the process of coating.

6. CE Certified

Technical Parameters

Product Name | MSK-AFA-IIID Compact Casting Coater with Automatic Drying Function | |

Product Model | MSK-AFA-IIID | |

| Installation Requirements | Operating Environment: Humidity: 10–85% RH (non-condensing at 25℃), Temperature: 0–45℃ 1. Water: Not required 2. Power: Single phase AC220V 50Hz. 3. Gas: Vacuum negative pressure (vacuum pump) 4. Workbench: Recommended 800×600×700 mm, load capacity ≥120 kg 5. Ventilation: No special requirements | |

Main Parameters (Specification) | 1. Power Supply: AC 220V, 50Hz, 10A (actual supply per device nameplate) 2. Total Power: 1050 W 3. Coating Base Size (L×W): 360 mm × 200 mm 4. Vacuum Adsorption Size (L×W): 300 mm × 150 mm 5. Coating Speed: 10–100 mm/s (stepless) 6. Coating Length: 0–300 mm or more (adjustable) 7. Adjustable Film Applicator (Scraper): KTQ150 type, width 150 mm, film thickness adjustable 0–5000 μm 8. Heating Method: Bottom vacuum plate heating 9. Maximum Heating Temperature: 120 ℃ 10. Temperature Control Accuracy: ±2 ℃ | |

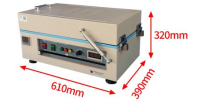

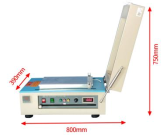

11. Product Specifications: · Dimensions: · Closed: 610 mm × 390 mm × 320 mm · Open: 800 mm × 390 mm × 750 mm · Weight: 40 kg |

| |

Standard Accessories

No. | name | qty | picture |

1 | Traverse Pusher | 1 pcs | |

2 | Collection Box | 1 pcs | |

3 | 150mm Micrometer Grade Adjustable Film Applicator | 1 pcs | |

| 4 | Vacuum Pump | 1 pcs | - |

5 | Material Cup | 1 pcs |

|

Optional Accessories

No. | name | functional type | picture |

1 | Micrometer Grade Adjustable Film Applicator - 50mm | (optional) |

|

2 | Micrometer Grade Adjustable Film Applicator - 100mm | (optional) |

|

3 | Vacuum Mixer | (optional) |

|

4 | Viscosity Tester/Meter | (optional) |

|

5 | 4-Paths Precision Film Applicator (for preparing films of 4 types of thickness) Coating widths available: 80 mm and 100 mm | (optional) |

|

| 6 | HDS-150 Hybrid Film Applicator: 100 mm wide extrusion head, can be fixed on the scraper, coating thickness adjustable from 0.005 mm to 0.02 mm. (Other widths available upon request) | (optional) |  |

7 | Box Preparer/ Box film Applicator | (optional) |

|

8 | Glass Plate | (optional) |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics