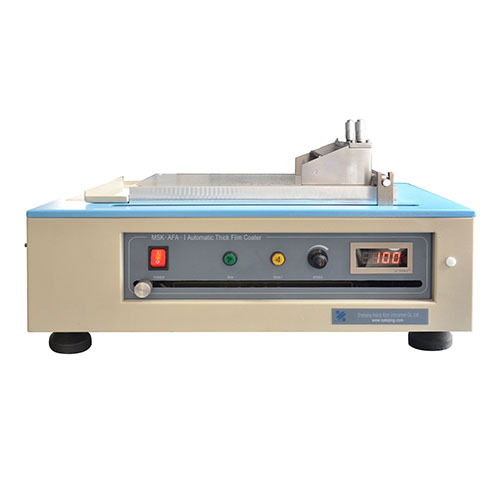

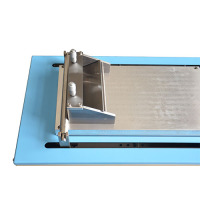

Compact Tape Casting Film Coater With Vacuum Chuck 300mm×150mm

MSK-AFA-I Automatic Coater is widely used in various high-temperature coating research, such as ceramic films, crystal films, battery material films, special nano films, and can adapt to future development of film-forming technology under high temperature conditions. The substrate is fixed by means of vacuum adsorption, so that there is no wrinkle phenomenon on the substrate during the coating process, and the coating is even smoother. The width of the film remain unchanged, and the film thickness can be adjusted according to the micrometer above the doctor blade.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction:

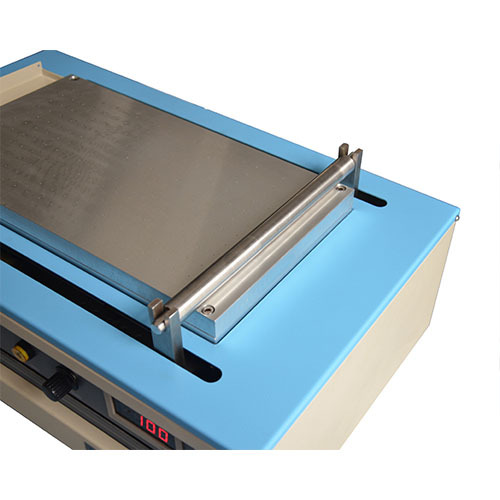

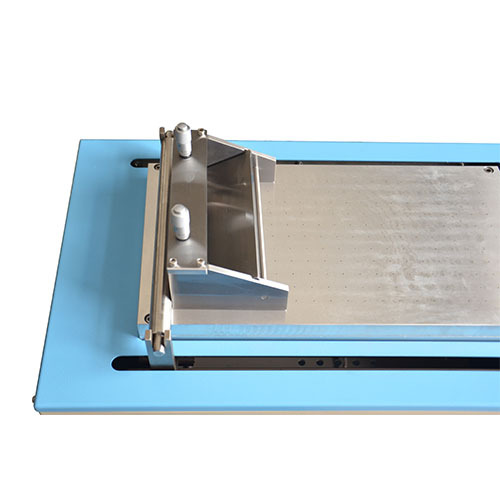

The MSK-AFA-I Automatic Coater is widely used for various high-temperature coating studies, such as ceramic films, crystalline films, battery material films, and special nanofilms, and can meet the needs of future high-temperature film formation technologies. The MSK-AFA-I fixes substrates using vacuum adsorption, preventing wrinkles during coating and ensuring a smooth and uniform film. The coating width remains constant, while the film thickness can be adjusted via a micrometer above the scraper: a smaller gap between the scraper and substrate produces a thinner film, while a larger gap produces a thicker film. The coating length can be controlled according to the scraper’s stroke, adjustable within 10–290 mm. The compact design of the MSK-AFA-I makes it suitable for use in various laboratories.

Main Features

1. The coating speed is adjustable with a digital display

2. The adjustable limit switch controls the coating travel distance.

3. The substrate is fixed by vacuum adsorption, and the substrate can be quickly taken and placed.

4. CE certified

Technical Parameters

Product Name | MSK-AFA-I Automatic Coater | |

Product Model | MSK-AFA-I | |

Installation Conditions | Operating environment: Humidity 10–85% RH (non-condensing at 25℃), Temperature 0–45℃. 1. Water: N/A 2. Electricity: AC220V 50Hz, must have good grounding 3. Air: Vacuum negative pressure (vacuum pump) 4. Workbench: size 800mm×600mm×700mm, bearing more than 120kg 5. Ventilation device: no need | |

Main Parameters (specification) | 1. Power supply interface: DC24V 3.75A (standard “power adapter” included) 2. Total power: ≤50W 3. Coating speed: 10mm/s-100mm/s adjustable 4. Coating length: ≥0–300 mm (adjustable) 5. Vacuum aluminum plate / chuck: 360mm×200mm (length×width) 6.Vacuum adsorption area: 300×150mm (length×width) 7. Adjustable film applicator (doctor blade): KTQ150 type, width 150 mm, film thickness adjustable 0–5000 µm | |

8. Product Specifications · Dimension: 610mm×390mm×240mm · Weight: 25kg |

| |

Standard Accessories

No. | name | qty | picture |

1 | Traverse pusher | 1 pcs |

|

2 | Collection box | 1 pcs |

|

3 | 150mm Micrometer Grade Adjustable Film Applicator | 1 pcs | |

| 4 | Vacuum Pump | 1 pcs | - |

5 | Material Cup | 1 pcs |

|

Optional Accessories

No. | name | functional type | picture |

1 | Micrometer Grade Adjustable Film Applicator - 50mm | (optional) | |

2 | Micrometer Grade Adjustable Film Applicator - 100mm | (optional) |

|

3 | Vacuum Mixer | (optional) | |

4 | Viscosity Tester/Meter | (optional) | |

5 | 4-Paths Precision Film Applicator (for preparing films of 4 types of thickness) Coating widths available: 80 mm and 100 mm | (optional) |

|

6 | Box Preparer / Box film Applicator | (optional) |

|

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics