Laboratory multifunctional coating machine

1. The maximum coating width of this Small multifunctional coating machine reaches 200mm, which is suitable for the preparation of various thin film materials.

2. The Small multifunctional coating machine is equipped with a precision temperature control system with a maximum heating temperature of 120℃.

3. We provide efficient and precise Small multifunctional coating machines for laboratories and R&D, suitable for small batch sample production.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of Lab coating machine:

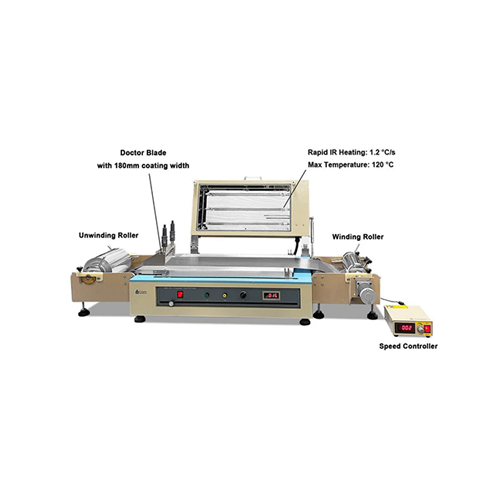

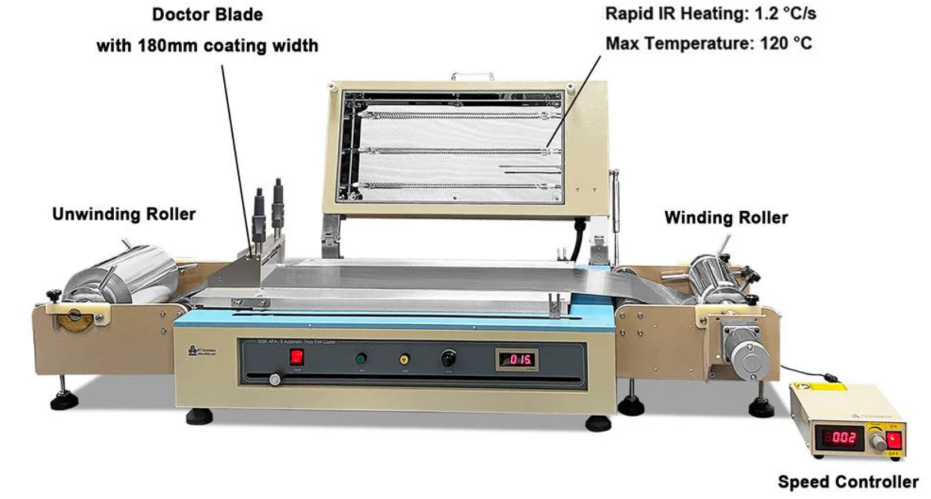

MSK-H200SR is a small and multifunctional Lab coating machine. Lab coating machine can realize single-sheet substrate coating and also supports roll-to-roll continuous coating, with a maximum coating width of 200mm. Lab coating machine is equipped with a thickness-adjustable scraper and an optional extrusion coating head to meet different process requirements.

Lab coating machine is a cost-effective film-making solution, which is widely used in the experimental preparation of various thin film materials such as battery electrodes, perovskite solar cell membranes, fuel cell membranes, etc., especially suitable for process exploration and small batch sample production in laboratories and R&D scenarios.

Technical parameters of Precision laboratory coating machine:

| Product name | MSK-H200SR 120℃ Multi-function precision laboratory coating machine | |

| Product model | MSK-H200SR | |

| Power supply | · Voltage of Precision laboratory coating machine: AC220V, 50/60Hz, single phase · Maximum power of Precision laboratory coating machine: 1850W | |

Long heated vacuum plate(Top Rapid Infrared Heating) (standard) | · Aluminum alloy vacuum plate, with tiny holes and adsorption substrate on the plate. · Rapid infrared heating on the top, no heating on the bottom. · Vacuum plate size: 600mm(L)×300mm(W). · Coating area: 250mm(W)×530mm(L). · Top-mounted rapid infrared heating · Maximum heating temperature: 120℃, heating rate 1.2℃/s. · Precision temperature control system, temperature control accuracy: ±1℃ | |

Short heated vacuum plate(Bottom Resistance Heating) (optional) | · Aluminum alloy vacuum plate, with tiny holes and adsorption substrate on the plate. · Bottom resistance heating. · Vacuum plate size: 400mm(L)×250mm(W). · Coating area: 200mm(W)×300mm(L) · The heating element is at the bottom of the vacuum plate,Maximum heating temperature 200℃. · Precision temperature control system, temperature control accuracy: ±1℃ · Due to the limited heating length, it is not suitable for low viscosity and high volatility slurry. | |

| Roll-to-roll system of Lab coating machine | · A small rewinding and unwinding system, maximum film width: 180mm · Motor speed range: 1-41rpm · Drive motor: 24V DC, can be used in Ar environment · Matching power adapter: 110–240VAC to 24VDC |  |

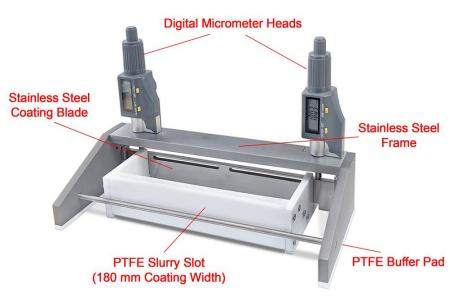

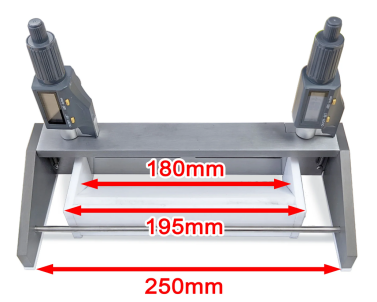

| Coating blade and extrusion device | ·Equipped with a hybrid film maker. ·Digital display micrometer adjustment head to adjust thickness. ·Scraper coating: width 180mm, coating thickness 20-200um. ·Extrusion coating: width 150mm, coating thickness 5-30um. |  |

| ||

| ·Equipped with a syringe pump to support extrusion coating. |  | |

Vacuum pump (optional) | ·Supports substrate adsorption during single-piece coating (optional). |  |

| Instrument specifications | ·Machine size: 1550mm(L) × 430(W) × 620mm(H) ·Net weight: 40kg |  |

| Compliance of Lab coating machine | CE Certified, UL or CSA certification is available at extra cost. | |

Logistics of Small multifunctional coating machine:

About our advantages:

1. Independent R&D and manufacturing capabilities:

Shenyang Kejing has independent R&D and production capabilities. All technologies are developed internally by the company to ensure product quality and technological leadership.

2. Efficient customer service:

The company focuses on customer needs, provides customized solutions, and can quickly respond to customers' technical support needs to improve customer experience and satisfaction.

3. Strong industry experience:

Shenyang Kejing has accumulated rich experience in multiple industry fields, especially in high-precision equipment and technological innovation, helping customers improve production efficiency and technical level.