Laboratory Multi Station Coater

1. The Laboratory pull film coating machine uses a touch screen, which is intuitive and convenient to operate.

2. The Laboratory pull film coating machine is relatively precise, fully automatically controlled, and adaptable to customer needs.

3. The Laboratory pull film coating machine is small in size and suitable for use in most spaces and places.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction:

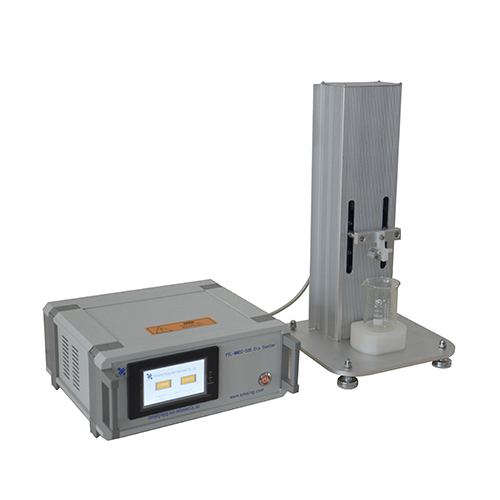

PTL-MM02-8P Dip Coater is a millimeter-scale, multi-station precision dip-coating device designed for research institutions. It is mainly used for preparing single-layer or multi-layer liquid-phase thin film materials by immersing one or more samples in different liquid phases. Featuring a compact structure, simple operation, and easy portability, it has been widely applied in universities, research institutes, and corporate laboratories.

Main features of Multi station dip coater:

1. Multi-sample/Multi-station: Supports simultaneous dip-coating of up to 5 samples in as many as 8 different liquid-phase materials, with up to 999 cycle repetitions (multi-layer coating).

2. Independent parameter settings: Each of the 8 stations can be individually set with different lifting speeds, immersion times, and drying times to meet diverse process requirements.

3. User-friendly operation: Equipped with a 4.3-inch color touchscreen featuring a simple and intuitive interface for easy operation.

4. High-precision control: PLC program-controlled high-precision stepper motor drive, combined with timing belt and ball screw transmission, ensures more accurate movement.

5. Space optimization: Compact design with high cost-performance ratio, saving valuable laboratory space.

Technical Parameters:

Product name | PTL-MM02-8P Lifting Coating Machine | |

Product model | PTL-MM02-8P | |

| Installation conditions | 1. Power supply: AC220V 50/60Hz. 2. Operating environment: Temperature 25℃ ± 15℃, humidity 55%Rh ± 10%Rh; dust-free, vibration-free, and free of flammable, explosive, or corrosive gases | |

1. Lifting main unit operating voltage: DC24V 5A (Standard: AC100–240V power adapter) 2. Total power: 100W 3. Type: Programmable – Room-temperature model 4. Drive motor: High-precision stepper motor 5. Speed setting range: · X-axis (shifting): 500–5000 mm/min · Z-axis (lifting): 1–200 mm/min 6. Dwell time: 1–999 s 7. Drying time: 1–999 s 8. Lifting stroke: 1–65 mm 9. Cycle count: 1–999 cycles 10. Sample lifting stations: 5 positions (can hold 1–5 substrates) 11. Dipping stations: 8 groups (each group with 5 sample cup positions) 12. Effective dipping depth: ≤65 mm 13. Substrate size range: (L: 75 mm) × (W: 25 mm) × (T: 2.5 mm) 14. Maximum lifting load: ≤250 g 15. Sample cup specification (beaker): 100 ml 16. Display & control: 4.3-inch color touchscreen | ||

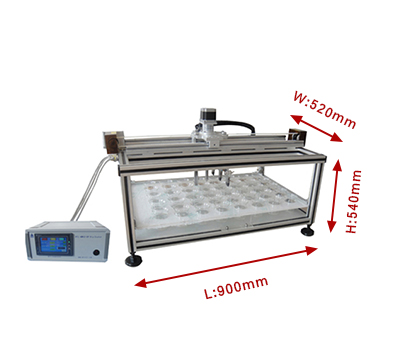

| Main parameters | 17.Product specifications: · Size: 900mm×520mm×540mm; · Weight: 20kg. |  |

Standard accessories of Laboratory pull film coating machine:

NO. | Name | Qty | Picture |

| 1 | Loading cup fixing plate | 1 pieces | - |

| 2 | Clip fixing plate | 1 pieces | - |

| 3 | Loading cup | 40 pieces | - |

| 4 | Clip | 5 pieces | - |

| 5 | Protective cover | 2 pieces | - |

Optional accessories of Multi station dip coater:

| NO. | Name | Function | Picture |

| 1 | Different sizes of loading cups and loading cup holders can be customized according to your needs. | (optional) | - |

| 2 | Constant temperature water tank (power: 800W; constant temperature: RT-70℃; temperature accuracy: ±1℃ without considering environmental influence; volume: 25L) (optional). | (optional) | - |

Warranty:

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)。

Logistics:

Company Profile:

Shenyang Kejing Auto-instrument Co., Ltd. was established in May 2000. Since the birth of the first SYJ-150 Low Speed Diamond Saw, Shenyang Kejing has been keeping the goal of leading the trend in the field of material analysis equipment. Up to now, the company has hundreds of products covering material cutting, grinding, polishing, film coating, mixing, rolling & pressing, sintering, analyzing and other fields as well as related consumables, which can meet the requirements on complete sets of sample preparation and analysis for crystal, ceramics, glass, rock, mineral, metal materials, refractory materials, composite materials, and biological materials.