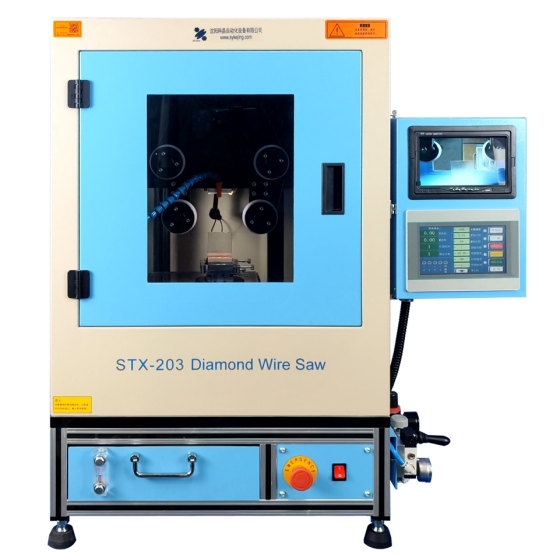

High Precision Diamond Wire Saw Machine

1. The cutting range of precision diamond wire saw machine is ≤φ150×150mm. The cutting accuracy is high

2. Precision diamond wire saw machine can choose the size of cutting wire: φ0.25/0.35/0.42mm to meet different cutting needs.

3. After setting the cutting program, the sample is fed continuously without manual adjustment, saving time and effort.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Introduction of precision vertical diamond wire saw:

STX-610 precision vertical diamond wire saw is a CE-certified cutting device. It is mainly used for precision cutting of material analysis samples, such as ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials and biomedical materials. Precision vertical diamond wire saw is particularly suitable for precision cutting of ultra-thin sheets, and the thickness of the sheet can reach 0.2mm. The cutting wire of precision vertical diamond wire saw adopts a single wire reciprocating motion mode, the usable wire length is long (150m), and the service life of one-time wire is long, which greatly improves the cutting efficiency. The tensioning wheel of precision vertical diamond wire saw adopts a pneumatic tensioning mode. The air pressure can be adjusted according to the thickness of the wire diameter. When the wire diameter is too thin, it can effectively protect the cutting wire from breaking due to excessive tension. When the cutting machine is used with an electric turntable, precision cutting can be performed, and the surface of the cut sample is in good condition, showing a frosted surface without wireless marks.

Advantages of precision diamond wire saw:

1. Precision diamond wire saw is suitable for precision cutting of brittle and easy-cleavage crystals.

2. Precision diamond wire saw uses diamond wire for cutting, and the cutting quality is excellent.

3. Precision diamond wire saw machine adopts aluminum profile structure, which is beautiful and light.

Technical parameters of precision diamond wire saw machine:

| Product Name | STX-610 Precision Vertical Diamond Wire Saw | |

| Product model | STX-610 | |

| Main parameters | 1.Power supply interface:three-pole socket with fuse AC220 50Hz 10A 2.Total power:≈500W 3.Main body structure:Aluminum alloy frame 4.Diamond wire length:≤150mm 5.Diamond wire diameter:φ0.25-0.45mm6.Diamond wire tensioning method:Adjustable pneumatic tensioner 7.Tensioning pressure adjustment range:0.1-0.4Mpa 8.Spindle cutting rotation method:Reciprocating rotation 9.pindle drive motor:AC frequency conversion + reducer AC220V 300W 10.Spindle speed:0-8m/s adjustable 11.Z-axis worktable effective stroke:≤160mm (the machine selection is subject to the actual product) 12.Y-axis worktable effective stroke:≤180mm 13.Z, Y-axis feed accuracy:0.01mm 14.Rotation angle table:Manual: Horizontal 0-360°15.Angle table:Manual:±15° 16.Y-axis, Z-axis, R-axis drive motor:Precision stepper motor 17.Maximum distance between the inner sides of the two guide wheels:≤180mm 18.Maximum workpiece diameter and length for cutting:φ150mm×150mm 19.Worktable center load-bearing capacity:≤10kg 20.Control method:PLC programmer + 7-inch touch screen 21.Parameter display form:digital 22.Remote control handle (tool setting) :Wired remote control handle23.Safety control device:Winding drum overtravel, wire breakage automatic stop, emergency stop switch 24.Machine weight:≈200kg | |

Compliance | CE Certified, UL or CSA certification is available at extra cost. | |

Electric Diamond Wire Saw Standard Accessories:

| NO. | Name | Qty | Picture |

| 1 | Polyethylene (PE) Tension Wheel | 2pc |  |

| 2 | Polyethylene (PE) Guide Whee | 2pc |  |

| 3 | Diamond Wire | 2pc |  |

| 4 | Water Pump | 1pcs |  |

| 5 | Resin Ceramic Block | 2pc |  |

| 6 | Paraffin Stick | 4pc |  |

Optional accessories for diamond wire saw stone cutting:

| NO. | Name | functional type | Picture |

| 1 | Diamond Cutting Wire (Ø0.25mm、Ø0.35mm、Ø0.42mm) | (functional) | |

| 2 | cutting oil | (functional) |  |

| 3 | mute oilless air compressor | (functional) |  |

FAQ:

1.For samples exceeding Φ150mmx150mm, are there any extension accessories or larger size equipment models?

Yes.

2.Do you have any recommended long-term cooperative accessories suppliers?

We not only produce equipment, but also accessories for related equipment. If you have any needs, you can contact us.

Why choose us?

1. Precision diamond wire saw machine adopts advanced manufacturing technology to ensure that diamond particles are evenly distributed, wire diameter is consistent, and tension is stable. The wire is not easy to break during cutting, the incision is smooth, the defective rate is reduced, and work efficiency is improved.

2. Precision diamond wire saw machine meets environmental protection requirements, does not produce harmful substances during the cutting process, has high cutting efficiency, helps to reduce energy consumption, and is in line with the concept of modern sustainable development.

About us:

Shenyang Kejing is located in Liaoning Province, covering a vast area, with advanced production equipment and complete production lines. The factory has multiple production areas and professional laboratories to provide strong guarantee for R&D, manufacturing and quality control. We strictly follow production standards to ensure that every piece of equipment meets international quality requirements. Through refined production processes and equipment management, we are able to efficiently meet customer needs.