Dual-Head High Vacuum Magnetron Plasma Sputtering Coater

VTC-600-2HD Dual-Head Magnetron Sputtering Coater is a high vacuum coating equipment newly developed by our company, and is used to prepare single-layer or multi-layer ferroelectric film, conductive film, alloy film, semiconductor film, ceramic films, dielectric film, optical film, oxide film, hard film, PTFE film, etc. VTC-600-2HD dual-head magnetron sputtering coater is equipped with two target guns and two power supplies, one RF power supply for sputter coating of non-conductive materials, and one DC power supply for sputter coating of conductive materials.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Product Introduction

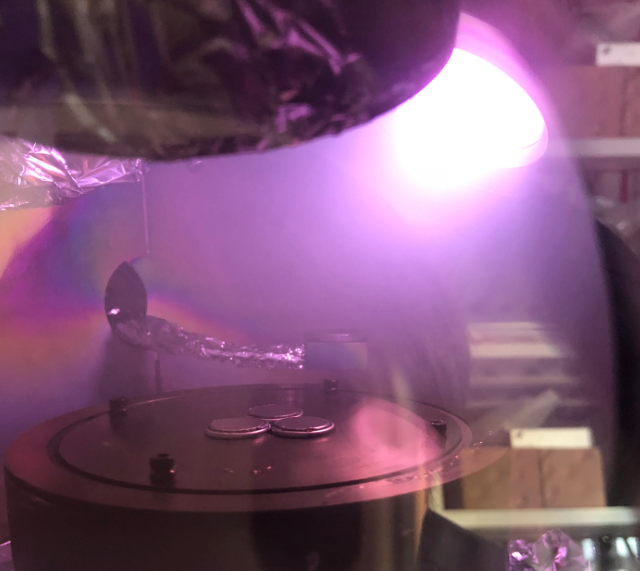

The VTC-600-2HD Dual-Head Magnetron Sputtering Coater is a newly developed high-vacuum coating system independently designed and manufactured by our company. It is suitable for preparing single-layer or multi-layer films such as ferroelectric films, conductive films, alloy films, semiconductor films, ceramic films, dielectric films, optical films, oxide films, hard coatings, and PTFE (polytetrafluoroethylene) films.

This system is equipped with two sputtering guns and two power supplies — one RF power supply for sputtering non-conductive materials and one DC power supply for sputtering conductive materials. An optional strong-magnetic target can also be configured for sputtering ferromagnetic materials.Compared with similar equipment, the VTC-600-2HD features a compact design, easy operation, and wide material compatibility, making it an ideal instrument for laboratory-scale thin film preparation across various material systems.

Main Features

1. It is equipped with two target guns, one RF power supply is used for sputter coating of non-conductive materials, and one DC power supply is used for sputter coating of conductive materials.

2. A variety of thin films can be prepared with a wide range of applications.

3. Small size and easy to operate

Technical Parameters

Product Name | VTC-600-2HD Dual-Head Magnetron Sputtering Coater | ||

Product Model | VTC-600-2HD | ||

Installation Conditions | 1.Workbench Requirements: 2.Water Supply: 3.Gas Supply: 4.Ventilation: 5.Power Supply: · Single-phase: AC220V 50Hz, 10A. 6.Environmental Conditions: · Operating temperature: 25℃ ±15℃; humidity: ≤55% RH ±10%. · The environment should be dry, dust-free, and free from flammable or explosive gases. | ||

Major Parameters (Specification) | Category | Specification | Remarks |

| Vacuum System | Vacuum Chamber Size:D φ300 × H265 mm | - | |

Vacuum Pump Set: • Turbo Pump: Hipace 80 | Original Pfeiffer (Germany) | ||

| Base Vacuum:5.0E-3 Pa (5.0E-5 hPa) | Required base vacuum before deposition | ||

Ultimate Vacuum:5.0E-4 Pa (5.0E-6 hPa) | Affected by site environment and system tightness | ||

Working Pressure:0.1–5 Pa (0.001–0.05 hPa) | Mainly argon; reactive gases can be added | ||

| Pumping Speed: • Foreline pump 1 m³/h; Turbo pump 67 L/s | Vacuuming time depends on pumping speed | ||

Power Supply Configuration | Power Type & Quantity: DC ×1, RF ×1 | DC:for metallic targets, RF:for insulating targets; (Optional strong magnetic target can be matched with the power type) | |

Output Power Range: • DC: 0–500W • RF: 0–300W | Power output mode / Maximum output power | ||

Matching Impedance:50Ω | Ensures power transmission efficiency and stability | ||

Gas Control | Working Gas:Standard: Argon (Ar) | Recommended: Ar, purity 99.999 | |

Gas Flow (2 Channels) • Channel 1: 1–100 sccm | Other types of protective gases can be customized if needed | ||

Flow Meter Accuracy:±1% F.S. | - | ||

| Rotating Sample Stage | Stage Size:Ø132 mm | ≈5.2 inches | |

Rotation Speed:1–20 rpm | Improves film uniformity | ||

Heating Temperature:RT~500°C | Sample stage surface temperature | ||

Temperature Accuracy:±1°C | - | ||

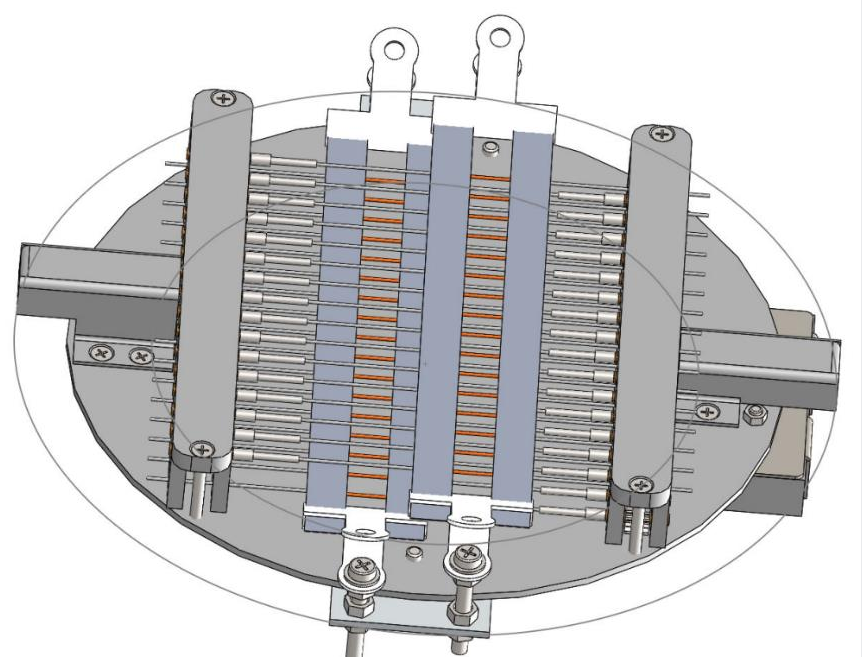

Magnetron Target | Target Quantity:2 pcs | Can be used independently or simultaneously | |

Target Size:Ø2 inches, thickness 0.1–5 mm | Thickness varies depending on target material | ||

Target–Substrate Distance:85–115 mm adjustable | Larger distance improves uniformity, slightly reduces rate | ||

Cooling Method:Water cooling | Water circulation to cool the target | ||

Deposition Performance & Others | Film Uniformity:±5% (for Ø100 mm substrate) | Key factors: optimized target–substrate distance and rotation speed | |

| Film Thickness Range:10 nm–10 µm | Excessive thickness may cause stress cracking | ||

Max. Power Input: • Main unit:500W; • RF power supply:1100W; • DC power supply:750W | The main unit, RF power supply, DC power supply, and film thickness monitor are all independently powered | ||

| Input Power: • Single-phase AC220V 50/60Hz | |||

Main Unit Dimensions:600mm × 750mm × 900 mm | Height with lid open: 1050 mm | ||

Overall Dimensions:1300m×750mm×900mm | Includes control and pump space | ||

| Total Weight:160kg | Compact structure with small footprint | ||

Standard Accessories

| No. | name | qty | picture |

| 1 | DC Power Supply Control System | 1 set | - |

| 2 | RF Power Supply Control System | 1 set | - |

| 3 | Film Thickness Monitoring System | 1 set | - |

| 4 | Turbo Pump (German imported or domestic with higher pumping speed) | 1 unit | - |

| 5 | Chiller | 1 unit | - |

| 6 | Polyester PU Tubing (Ø6 mm) | 4m | - |

Optional Accessories

| No. | name | Function Category | picture |

| 1 | Various target materials such as gold, indium, silver, platinum, etc | Optional | - |

| 2 | Optional strong magnetic target for sputtering ferromagnetic materials | Optional | - |

| 3 | Double-layer rotating deposition fixture | Optional |  |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics