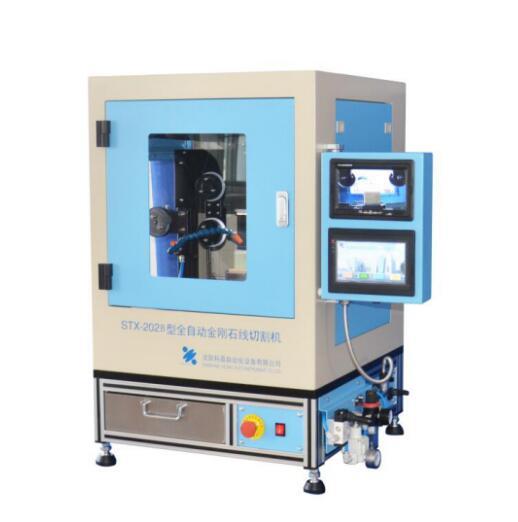

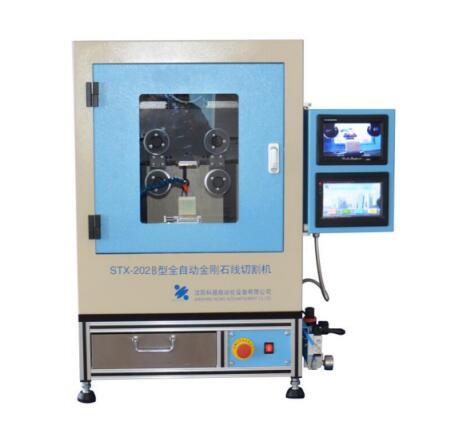

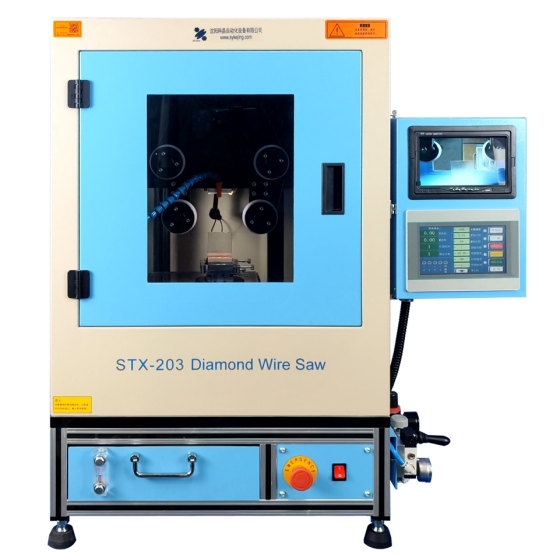

Diamond Wire Saw With Outside Cover

1. STX-202B Exterior Shielded Diamond Wire Saw is specially designed for material researchers for precision cutting of brittle material samples.

2. The rotating table of Diamond wire saw with protective chamber can also cut samples at a certain angle.

3. Diamond wire saw with protective chamber is a diamond wire saw that can perform continuous cutting. After setting the cutting program, the sample is fed continuously without manual adjustment. After cutting, the sample size has a high dimensional accuracy within the range of ±10μm.

4. The cutting wire of Diamond wire saw with protective chamber adopts a single-wire reciprocating motion mode, and the life of a single wire change is long, which improves the cutting efficiency. When used for ultra-thin precision cutting, the sample thickness (within about 1 inch) can reach 0.08mm.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Introduction of Electric Angle Stage Diamond Wire Saw:

STX-202B Fully Automatic Diamond Wire Saw is specially designed for material researchers. It is used for precision cutting of fragile material samples, allowing slicing and cutting, and the rotary stage enables angled cuts on samples. The machine can cut materials such as ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials.

STX-202B is a continuous-cutting diamond wire saw. Once the cutting program is set, samples are fed continuously without manual adjustment, ensuring high dimensional accuracy of the cut samples. This fully automatic diamond wire saw uses a single wire in a reciprocating motion, providing a long usable wire length and extended service life per installation, improving cutting efficiency. For ultra-thin precision cutting, the thickness of the cut slices (within approximately 1 inch) can reach 0.08 mm.

Advantages of Diamond Wire Saw with Exterior Guard:

1. Diamond Wire Saw with Exterior Guard is equipped with a protective chamber to avoid contamination by hazardous dust.

2. The digital control panel in the external chamber of Diamond Wire Saw with Exterior Guard is used to control cutting parameters.

3. The digital microscope view on the external panel of Diamond Wire Saw with Exterior Guard allows precise positioning to initialize the first cut.

Exterior Shielded Diamond Wire Saw Specifications:

| Product Name | STX-202B Fully Automatic Diamond Wire Saw | |

| Product Model | STX-202B | |

| Installation conditions of diamond wire saw with protective chamber | 1. Temperature and humidity: 10-85%RH (at 25℃ without condensation) Temperature: 0-45℃. 2. There is no strong vibration source and corrosive gas around the equipment. 3. Coolant: required (cutting oil is recommended). 4. Power supply: single phase: AC220V 50Hz 5. Air source (compressed air): ≥0.6Mpa. 6. Workbench size: recommended 800mm×700mm×500mm load-bearing 150kg or more (solid cement table is best) 7. Ventilation device: no special requirements. | |

| Function and application of diamond wire saw with protective chamber | 1. Ceramic materials: alumina ceramics, zinc oxide ceramics, zirconium oxide ceramics, target ceramics,honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc.; 2. Crystal materials: graphite, silicon crystals (solar polycrystalline silicon, single crystal silicon), sapphire,alumina crystals, infrared glass crystals, aluminum oxide crystals, silicon carbide crystals, cesium iodide crystals, etc.; 3. Glass materials: chalcogenide glass, optical glass, quartz glass, infrared glass, glass tubes, etc.; 4. Metal materials: iron, aluminum, copper, titanium alloy, magnesium alloy and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc.; 5. Composite materials: PVC board, carbon fiber composite materials, glass fiber composite materials, etc. 6. Rock materials: natural rocks, jade, meteorites, Pei Cui, agate, etc. precision cutting;Precision slicing of various high-value materials; slicing of geological light slices, geological thin slices (sedimentary rocks, igneous rocks, metamorphic rocks, ores), etc. 7. Thermoelectric materials: bismuth telluride, lead telluride, silicon-germanium alloy, etc. 8. Infrared optical materials: crystals such as zinc selenide, zinc sulfide, silicon, germanium, etc. 9. Biomedical materials: Bioplastic specimen sections (human and animal organs, combined sections of soft and hard tissues of the jaw, implant observation, dental crowns and bridges, histological specimens such as teeth); Combined sections of soft and hard tissues of orthopedics (fresh and hard tissues such as femur, hip joint, vertebral body, bone histological samples with implants, etc.); Medical tissue sections such as cardiovascular stent sections and stone sections; ...... Note: Materials with a hardness less than that of diamond wire can also be accurately cut by our Exterior Shielded Diamond Wire Saw. | |

| Dimensions and weight of Diamond wire saw with protective chamber |

| |

| 20.Product Specifications: · Dimensions: 730 mm × 680 mm × 970 mm · Weight: Approximately 130 kg |

| |

Standard accessories for Exterior Shielded Diamond Wire Saw:

No. | name | qty | picture |

1 | Tension Wheel | 2 pcs |

|

2 | Leading Wheel | 2 pcs | |

3 | Cross (Mount) Vise | 1 set | |

4 | Diamond Cutting Wire | 3 rolls | |

5 | Water Pump | 1 pcs | |

6 | Resin Bonded Ceramics | 2 pcs |

|

7 | Wax Bar | 4 pcs |

|

Optional accessories for Exterior Shielded Diamond Wire Saw:

No. | name | functional type | picture |

1 | Diamond Cutting Wire (Ø0.35mm, Ø0.42mm) | (optional) |

|

2 | Cutting Oil | (optional) |

|

3 | Geological Slice Cutting Fixture | (optional) |

|

4 | Heating Plate | (optional) | |

5 | Portable Microscope (3R Wireless Digital Microscope) | (optional) | |

6 | Mute Oil-less Air Compressor | (optional) | |

7 | DX-100 Single Crystal Direction-Finder | (optional) | |

Operating Instructions for Diamond Wire Saw with Enclosed Exterior:

1. The saw must be used with an appropriate cutting fluid to prevent corrosion of machine parts. We strongly recommend that you use an oil-based coolant or lubricant mixed with water. Do not use tap water directly. If the parts of the Diamond Wire Saw with Enclosed Exterior are rusted, they are not covered by the warranty.

2. Do not over-rinse the sample table, otherwise it may cause rust on the Z-axis stepper motor.

3. Before using the Diamond Wire Saw with Enclosed Exterior product for the first time or before continuing to work for 150 hours, add 10-15 drops of anti-wear hydraulic oil (ISO 32) from the oil can (#19).

A limited amount of grease should be added to the motor shaft regularly (universal grease is sufficient).

4. Never cut any material with the Diamond Wire Saw with Enclosed Exterior without using an appropriate cutting fluid. If you do so, the reel drive mechanism may be severely damaged.

5. In order to cut sticky materials (such as non-ferrous alloys, epoxies, and plastics), you must sharpen the diamond wire frequently. We recommend cutting the sample along with the included dressing stone (stick the sample and dressing stone side by side and cut together, this process will help keep the wire sharp enough for efficient cutting.

6. After each use of the Diamond Wire Saw with Protective Cover, please clean the machine.

Diamond Wire Saw with Protective Cover Product Warranty:

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

About us:

We are particularly focused on the research and development and sales of Exterior Shielded Diamond Wire Saw products. Our Exterior Shielded Diamond Wire Saw products are widely used in many fields, so that each Exterior Shielded Diamond Wire Saw can always maintain the best performance.