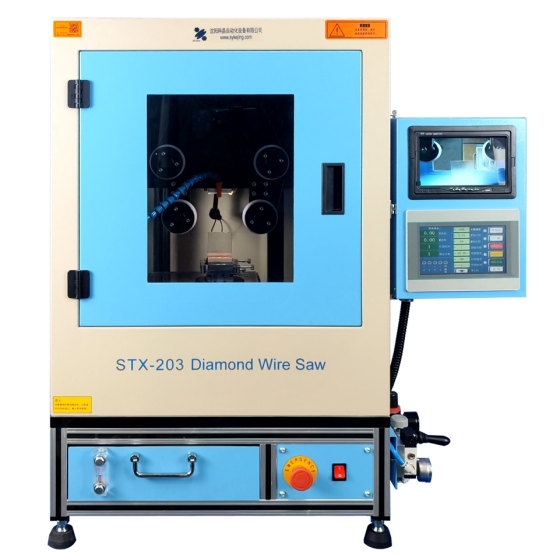

Diamond Wire Saw For Cutting Max. 600mm With Protective Cover

1.STX-2401B Ddiamond wire saw for cutting with protective cover is suitable for cutting samples of different hardness,

2.Diamond wire saw for cutting with protective cover is mainly used for processing larger precious metal materials, and the cutting size can reach 24 inches.

3.Diamond wire saw for cutting with protective cover has small cutting slits and excellent cutting blade quality, which greatly improves the utilization rate of materials.

- Shenyang Kejing

- Shenyang, China

- 22 working days

- 50 sets

- Information

Main Features Of Diamond Wire Saw With Protective Cover Cutting:

1. Diamond wire saw with protective cover cutting is suitable for cutting large samples, especially samples over 12", which is the best choice for slicing large samples.

2. Diamond wire saw with protective cover cutting drives the diamond wire to move downward at a constant speed, and the material is fixed on the workbench to ensure stable cutting.

3. The workbench of Diamond wire saw with protective cover cutting can be adjusted 360˚ manually or by program control.

4. Diamond wire saw for cutting with protective cover tools adopts a pneumatic tensioning system with imported pneumatic components, making the tensioning force more stable and reliable.

5. Diamond wire saw for cutting with protective cover tools PLC program control system, large-size touch screen, easy and fast operation.

6. Diamond wire saw for cutting with protective cover tools can design various matching tooling fixtures according to user needs.

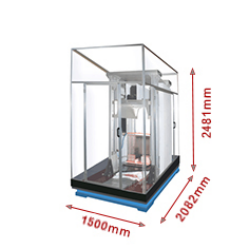

7. Diamond wire saw for cutting with protective cover tools is equipped with a full protective cover, which is safe, quiet and environmentally friendly.

Technical Parameters:

Product Name | STX-2401B Diamond wire saw with protective cover cutting | |

Product Model | STX-2401B | |

Mounting Conditions | 1. This equipment is required to be used at an altitude of 1000m or less, with a temperature of 25℃±15℃, and a humidity of 55%Rh±10%Rh. 2. Water: N/A 3. Electricity: AC220V, 50Hz 4. Gas: air source (0-1Mpa) 5. Workbench size: 1700mm×2200mm×2600mm 6. Ventilation: required | |

Major Parameters (Specifications) | 1. Power supply: 220V 50Hz 2. Total Power: 3.2 kW 3. Main Structure: Cast iron base + aluminum alloy frame (2401B with transparent enclosure) 4.Total length of cutting wire: ≤270m 5.Diameter of cutting wire: ≤0.45mm 6.Tensioning mode: pneumatic tensioning 7.tensioning air pressureAdjustment Range: 0.1–0.4 MPa 8.Spindle Cutting Rotation Mode: Reciprocating Rotation 9.Spindle Drive Motor Specifications: Servo Motor, IN 3φ AC 125V, 1.5 kW, 8.0 A 10.Cutting wire feeding speed: 0-8m/s adjustable 11.cutting speed setting range: 0.05~30mm/min 12.Return Speed: 1–150 mm/min 13.Z-axis travel distance: ≤680mm 14.Y-axis travel distance: ≤660mm 15.R-axis Rotary Worktable: Electric, Horizontal 0–360° 16.Z-axis and R-axis Drive Motors: Servo Motors 17.Y-axis Drive Motor: Precision Stepper Motor 18.Y-axis feeding indication accuracy: 0.01mm 19.Maximum Inner Distance Between Two Guide Wheels: ≤900 mm 20.Maximum Workpiece Diameter and Length: Φ600 mm × 650 mm 21.workbench size: 700mm×700mm 22.Workbench load: ≤600kg 23. Control system and control mode: PLC Controller + 7-inch Color Touchscreen 24.Display mode: digital display 25.Safety control device: automatic stop when disconnected, emergency stop switch | |

26.Dimension and Weight ·Dimension:2082mm×1500mm×2481mm ·Net weight: about 1600kg |  | |

| Functions and Applications | 1. Ceramic materials: aluminum oxide ceramics, zinc oxide ceramics, zirconium oxide ceramics, target ceramics, honeycomb ceramics, semiconductor ceramics, conductive ceramics, non-conductive ceramics, etc. 2. Crystal material: graphite, silicon crystal (solar polysilicon, single crystal silicon), sapphire, aluminum oxide crystal, infrared glass crystal, aluminum oxide crystal, silicon carbide crystal, cesium iodide crystal, etc. 3. Glass materials: chalcogenide glass, optical glass, quartz glass, infrared glass, glass tube, etc. 4. Metal materials: iron, aluminum, copper, titanium alloy, magnesium alloy and other metals and alloys, non-ferrous metals (zinc sulfide, ferrite), etc. 5. Composite materials: PVC board, carbon fiber composite material, glass fiber composite material, etc. 6. Rock material: precision cutting of natural rock, jade, meteorite, jadeite/emerald, agate, etc. Precise slices of various high-value materials; geological slices, geological slices (sedimentary rocks, magmatic rocks, metamorphic rocks, ore) and other square slices. 7. Thermoelectric materials: bismuth telluride, lead telluride, silicon germanium alloy, etc. 8. Infrared optical materials: zinc selenide, zinc sulfide, silicon, germanium and other crystals 9. Biomedical materials: Bioplasticized specimen slices (human and animal organs, combined sections of soft and hard jaw tissues, implant observation, dental crowns and bridges, teeth and other histological specimens); Orthopedic soft and hard tissue joint sections (femoral, hip, vertebral body and other fresh tissue and hard tissue, bone histological samples with implants, etc.); Cardiovascular and cerebrovascular stent slices, calculi slices and other medical tissue slices Note: Precision cutting can be performed for materials with hardness less than diamond wire. | |

Compliance | CE Certified, UL or CSA certification is available at extra cost. | |

Standard Accessories:

No. | name | qty | picture |

1 | Diamond Wire (2500m) | 1 pcs |

|

2 | Remote Control | 1 pcs |

|

3 | Circulating Coolant Tank | 1 pcs | Including water pump, hose and connector |

4 | Water-Protection Cover | 1 set | Used at both sides of the saw and at the spooler |

5 | Wire Installer | 1 set |

|

Optional Accessories

No. | name | functional type | picture |

1 | Diamond Cutting Wire (Ø0.145, Ø0.25, Ø0.35, Ø0.42mm) | (optional) |

|

2 | Cutting Oil | (optional) |

|

3 | Mute Oil-less Air Compressor | (optional) | |

4 | DX-100 Single Crystal Direction-Finder | (optional) | |

5 | Dust-Protection Cover | (optional) | |

Warranty:

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Company Profile:

Shenyang Kejing Automation Equipment Co., Ltd. was established in May 2000. Since the birth of the first SYJ-150 low-speed diamond cutting machine, Shenyang Kejing has begun its development process with the goal of surpassing foreign counterparts and leading the trend of material analysis equipment. To date, it has hundreds of products covering the fields of material cutting, grinding, polishing, coating, coating, mixing, rolling, sintering, analysis, and related consumables, which can meet the full set of needs for the preparation and analysis of crystals, ceramics, glass, petrographic phases, mineral samples, metal materials, refractory materials, and composite materials.