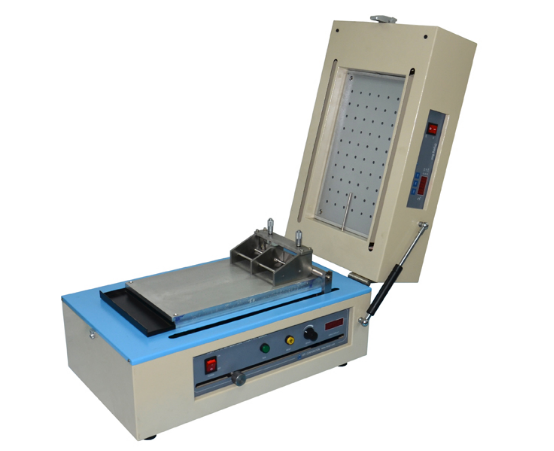

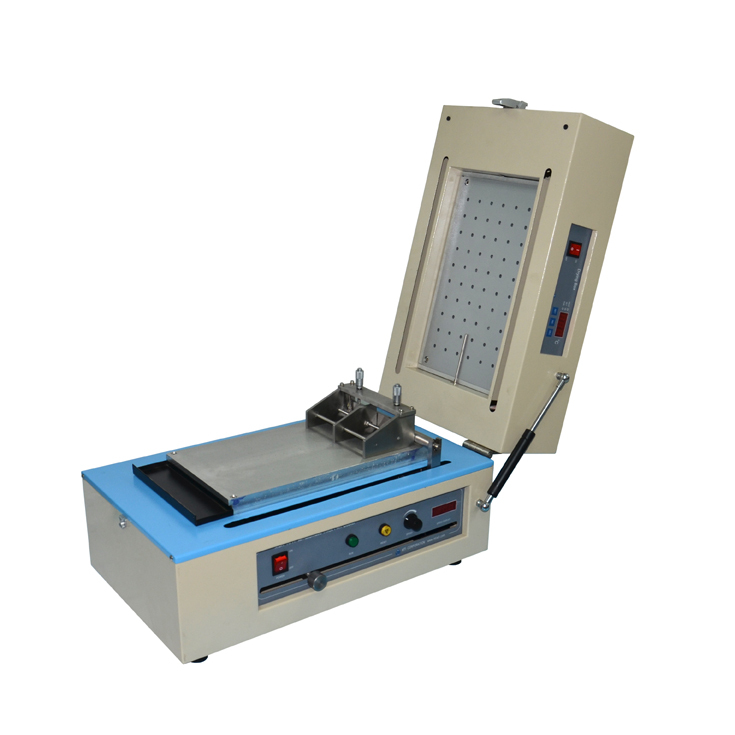

Compact Tape Casting Film Coater With Top Heating Cover -

MSK-AFA-III compact casting coater with automatic drying function achieves smooth and uniform coating effect by advancing/propelling/pushing the precision film applicator at a constant speed. After coating, the upper cover can heat and dry the film, and the temperature control accuracy is ±1°C.

- Information

Product Introduction

The MSK-AFA-III Small Automatic Casting and Drying Coater is widely used in various high-temperature coating studies, such as ceramic films, crystal films, battery material films, and special nanofilms, and is capable of meeting the development needs of future high-temperature film-forming technologies. The MSK-AFA-III achieves smooth and uniform coating by steadily advancing a precision casting applicator, with the advancement speed adjustable according to user requirements. Substrates are fixed using vacuum adsorption to prevent wrinkles during coating, ensuring a smooth application. After coating, the top cover can heat and dry the film with a temperature control accuracy of ±1°C. This machine is especially suitable for the preparation of solid electrolytes and lithium battery electrodes.

Main Features

1. With automatic drying function.

2. Vacuum adsorption is adopted to fix the substrate.

3. uniform coating

4. CE Certified

Technical Parameters

Product Name | MSK-AFA-III Compact Casting Coater | |

Product Model | MSK-AFA-Ⅲ | |

Installation Conditions | 1. Operating Environment: Humidity: 10–85% RH (at 25℃, non-condensing); Temperature: 0–45℃ 2. Power: Single-phase AC220V 50Hz, 10A 3. Gas: Vacuum negative pressure (vacuum pump) | |

Main Parameters (Specification) | 1. Power Interface: · Dual power supply: Lower: DC24V 3.75A (standard “power adapter”) · Upper heating: AC220V 50Hz 10A 2. Total Power: 1050W 3. Coating Base Suction Plate Material: Aluminum 4. Coating Base Size (L × W): 360mm × 200mm 5. Vacuum Adsorption Size (L × W): 300mm × 150mm 6. Coating Speed: 10–100mm/s (stepless adjustable) 7. Coating Length:0–300mm (adjustable) 8. Adjustable Coating Blade (Doctor Blade): KTQ150 type, width 150mm, film thickness adjustable 0–5000 µm 9. Heating Method: Upper heating 10. Maximum Heating Temperature: 120℃ 11. Temperature Control Accuracy: ±2℃ 12. UV Lamp Baking: Not available 13. Air Source: Vacuum negative pressure (oil-free vacuum pump) | |

14. Product Specifications · Outline dimensions: Closed state: 610mm (L) × 390mm (W) × 340mm (H) · Weight: 50kg | ||

Standard Accessories

No. | name | qty | picture |

1 | Traverse Pusher | 1 pcs | |

2 | Collection Box | 1 pcs | |

3 | 150mm Micrometer Grade Adjustable Film Applicator | 1 pcs | |

| 4 | Vacuum Pump | - | |

5 | Material Cup | 1 pcs |  |

Optional Accessories

No. | name | functional type | picture |

1 | Micrometer Grade Adjustable Film Applicator - 50mm | (optional) | |

2 | Micrometer Grade Adjustable Film Applicator - 100mm | (optional) |

|

3 | Vacuum Mixer | (optional) | |

4 | Viscosity Tester/Meter | (optional) |  |

5 | 4-Paths Precision Film Applicator (for preparing films of 4 types of thickness) Coating widths available: 80 mm and 100 mm | (optional) |  |

| 6 | HDS-150 Hybrid Film Applicator: 100 mm wide extrusion head, can be fixed on the scraper, coating thickness adjustable from 0.005 mm to 0.02 mm. (Other widths available upon request) | (optional) |  |

| 7 | Box Preparer/ Box Film Applicator | (optional) |  |

Logistics