Automatic Slurry Feeder for feeding polishing slurry

SKZD-3 Slurry Feeder is used in conjunction with UNIPOL series lapping machine. It is uniquely used for feeding of suspension polishing slurry (such as Silicon dioxide, diamond suspension).

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

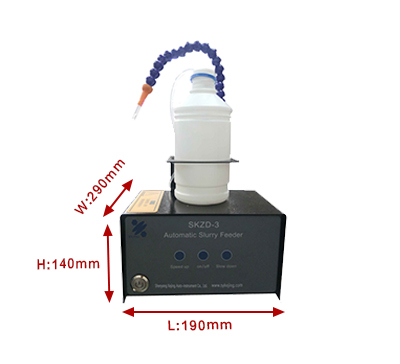

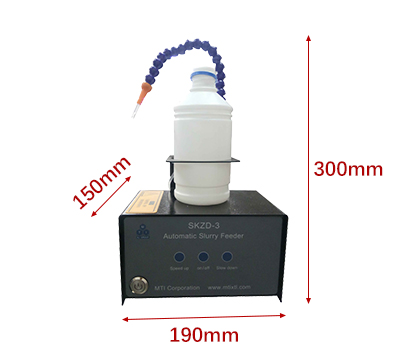

The SKZD-3 Drip Feeder is designed to be used in conjunction with the UNIPOL series grinding and polishing machines. Featuring a simple structure and compact size, it can be directly placed on the polishing machine to dispense abrasives. Since it does not include a stirring function, it is specifically intended for dispensing suspension-based polishing liquids such as silica or diamond suspensions.

The SKZD-3 Drip Feeder enables automatic control of polishing liquid dispensing during the polishing process, with a uniformly adjustable drip rate. This not only saves labor but also reduces polishing liquid consumption, ensuring the liquid is evenly distributed over the sample surface, thereby greatly improving polishing efficiency.

Main Features

1. The feeding speed of polishing slurry can be adjusted according to actual technological requirements.

2. It is uniquely used for feeding of suspension polishing slurry.

Technical Parameters

Product Name | SKZD-3 Slurry Feeder | |

Product Model | SKZD-3 | |

| Installation Requirements | 1. Temperature and Humidity: 10–85% RH (at 25℃, non-condensing); Temperature: 5–45℃. 2. The equipment should be placed in an environment free from strong vibrations and corrosive gases. 3. Power Supply: Single-phase AC100–240V, 50/60Hz, with a standard Chinese two-/three-pin socket, 10A (the socket must be equipped with a reliable safety ground). 4. Workbench: It is recommended to use on a stable workbench or tabletop. 5. Ventilation: A well-ventilated environment is required; no special ventilation system is needed. | |

Main Parameters (Specification) | 1. Equipment Power Port: DC12V 2A Standard Power Adapter: IN: AC100–240V, OUT: DC12V 2A 2. Dispensing Station (Dispensing Pump): 1 unit 3. Reservoir Bottle Capacity: 500 ml/bottle 4. Drive Method: Precision Stepper Motor + Peristaltic Pump 5. Dispensing Method: Peristaltic Quantitative Dispensing 6. Dispensing Type: Suspension 7. Silicone Tube Specifications: Outer Diameter: Ø3.2 mm; Inner Diameter: Ø1.6 mm 8. Suspension Flow Rate: 0.15–6 ml/min (adjustable range) | |

Product Dimension and Weight | Dimension: L190mm×W150mm×H300mm Weight: 2.5kg |

|

Warranty

· One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics