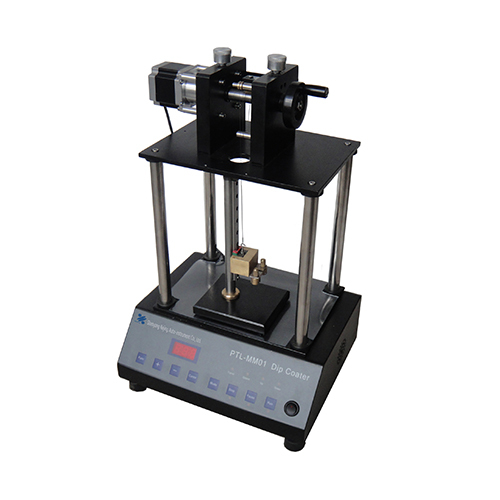

6 Position Millimeter Dip Coater With Speed 1-200 mm/min

1. Under the same external conditions, the dip coater can coat up to 6 samples at the same time.

2. The sample coating time, dipping time and drying time can be set through the dip coater program.

3. After one plating process is completed, the feeding cup is manually rotated to allow the sample to enter the next plating process. A constant temperature box is also provided.

- Shenyang Kejing

- Shenyang, China

- 10 working days

- 50 sets

- Information

Product Introduction

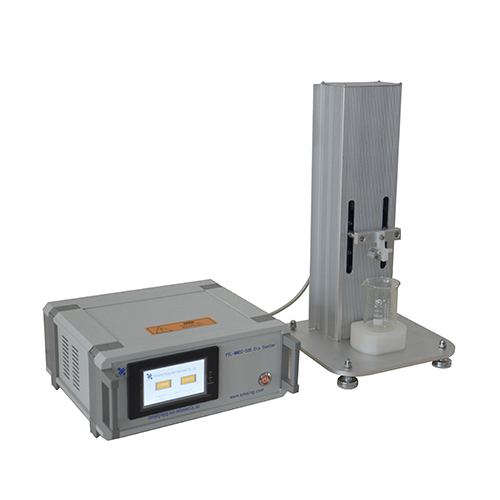

The PTL-OV6P Six-Position Dip Coater is a millimeter-scale multi-position precision dip-coating system with temperature control, specifically designed for research institutions and suitable for the preparation of solution-processed thin film materials. Featuring a compact structure, easy operation, and convenient portability, it has been widely adopted in universities, research institutes, and corporate laboratories.

Main Features of 6 Position Millimeter Dip Coater:

1. Multi-Position Switching: Equipped with six positions, allowing multiple samples to be dip-coated in one cycle. Manual switching between positions makes operation intuitive and convenient.

2. Working Environment: Integrated with a constant-temperature heating chamber, the system can operate at room temperature or under preset heating conditions, meeting the requirements of temperature-sensitive processes.

3. User-Friendly Operation: A 4.3-inch color touchscreen provides a clean and intuitive interface, enabling beginners to operate the system with ease.

4. High-Precision Control: A PLC program combined with suspended wire-drive technology effectively minimizes vibration interference.

5. Space Optimization: Compact design with high cost-effectiveness, saving valuable laboratory space.

Technical Parameters of 6 Position Millimeter Dip Coater:

Product Name | PTL-OV6P 6-Position Millimeter Dip Coater | |

Product Model | PTL-OV6P | |

Installation Conditions | 1. Power supply: AC220V, 50/60Hz. 2. Site environment: Temperature 25℃ ±15℃, humidity 55%Rh ±10%Rh; free of dust, vibration, flammable, explosive, and corrosive gases. | |

Main Parameters (Specification) | 1. Lifting main unit working voltage: DC24V 3.75A (Standard configuration: AC100~240V power adapter) 2. Lifting main unit power: 50W 3. Type: Program-controlled – Constant temperature model (with heating chamber) 4. Drive motor: High-precision stepper motor 5. Speed setting range: 1–200 mm/min 6. Dwell time: 1–999 s 7. Drying time: 1–999 s 8. Lifting stroke: 1–75 mm 9. Number of lifting cycles: 1–20 times 10. Lifting stations: 6 11. Effective dipping depth: ≤60 mm 12. Sample substrate size range: (L: ≤95 mm, >40 mm) × (W: ≤50 mm) × (t ≤3.5 mm) 13. Maximum total lifting load: ≤300 g 14. Beaker specification: Φ60, 150 ml 15. Beaker tray load capacity: Total ≤3000 g (≤500 g per station) 16. Display & control: 4.3-inch color touchscreen 17. Overall dimensions: 455 mm (L) × 500 mm (W) × 1050 mm (H) 18. Equipment weight: ≈45 kg (including heating chamber) 19. Heating chamber specifications: · Temperature range: RT (room temperature) ~ +100℃ · Temperature control/setting: Dual 7-segment digital display PID / 4-button touch setting · Heating timer: 0–9999 minutes or hours · Rated heating power: 0.8 kW · Rated current: 3.6 A · Operating voltage: AC220V 50/60Hz · Internal dimensions (capacity): 310 mm × 310 mm × 310 mm (30 L) · External dimensions: 455 mm (L) × 500 mm (W) × 723 mm (H) | |

Standard Accessories

| No. | Name | Quantity | Image |

| 1 | Coating Fixture | 1 set | - |

| 2 | Material Cups | 6 pcs | - |

| 3 | Lifting Wires | 3 pcs | - |

Optional Accessories

| No. | Name | Function Category | Image |

| 1 | Multiple Fixtures | Optional | - |

Warranty

One year limited with lifetime support (not including rusted parts due to inadequate storage conditions)

Logistics

Why choose our Programmable Dip Coater:

1. Our 6 Position Millimeter Dip Coaters use advanced nano-coating technology to provide efficient coating speed and precise coating thickness control to meet high-end application requirements.

2. We are committed to every detail of the product, and each device has passed rigorous inspection and testing to reach the industry-leading level.

3. The 6 Position Millimeter Dip Coater is equipped with a precise adjustment system, the coating speed can be adjusted in a wide range, and the coating quality is consistent and controllable each time.

4. The product supports the coating of a variety of materials, including different types of nanomaterials and films, and flexibly adapts to different experimental needs.

5. The efficient coating speed and multi-station design can greatly improve production efficiency, reduce waiting time in experiments and production, and thus reduce overall costs.

6. Made of high-quality materials, the equipment structure is stable and there will be no performance degradation after long-term use.

7. Provide comprehensive technical support and after-sales service, including equipment installation, commissioning, operation training and maintenance services, to ensure that every customer's needs are responded to in a timely manner.

8. Our Programmable Dip Coaters have market-competitive prices while ensuring high performance and high quality, helping customers achieve higher output value at a lower cost.